Nut automatic feeding and marking die

An automatic feeding and mold technology, applied in typewriters, printing and other directions, can solve the problems of low marking efficiency, product deformation, and too deep marking, and achieve the effect of smooth and bright surface, preventing product deformation, and facilitating material feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings are for illustrative purposes only and cannot be construed as limiting the patent;

[0031] In order to better illustrate this embodiment, some parts in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product;

[0032] For those skilled in the art, it is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

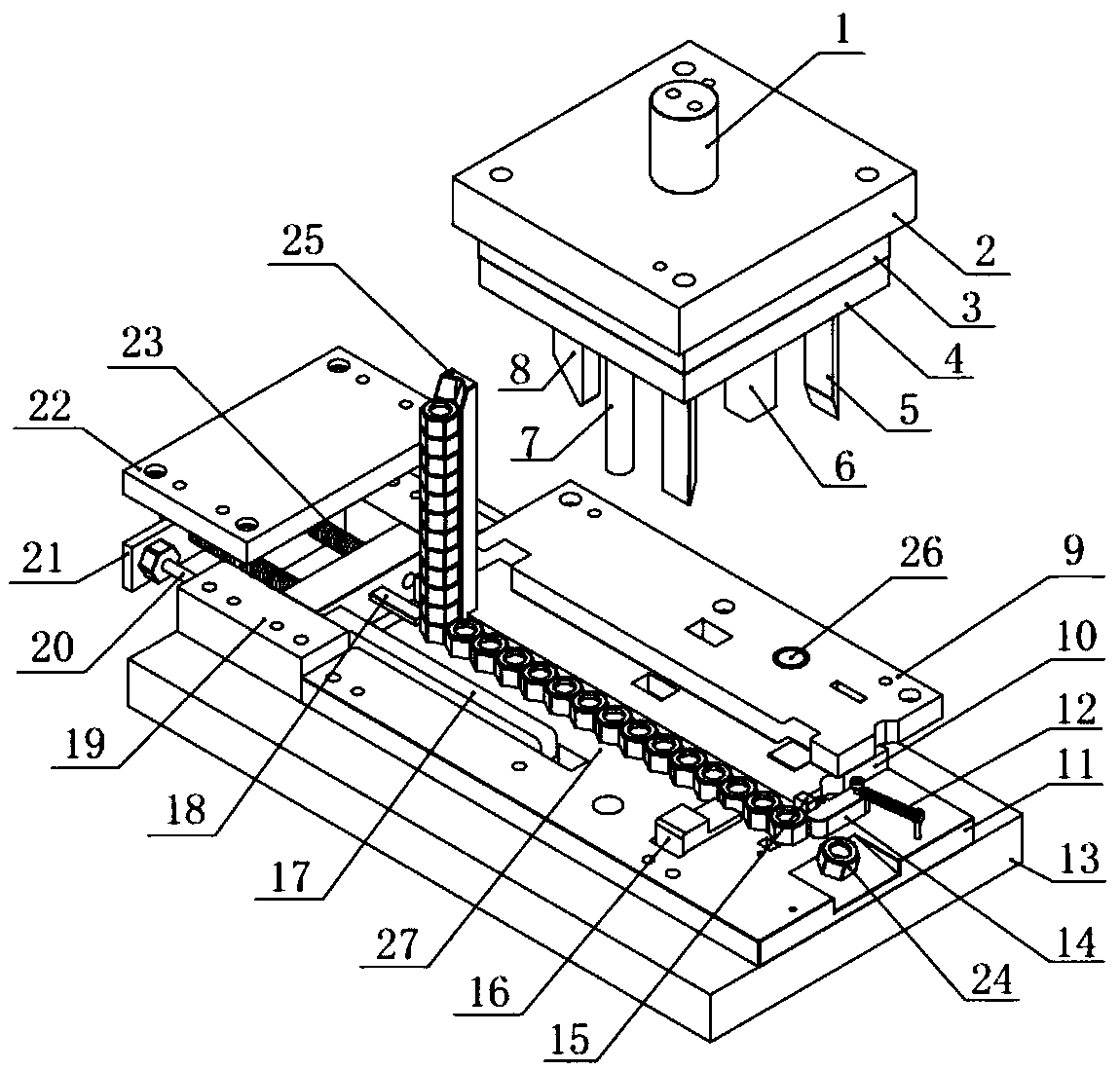

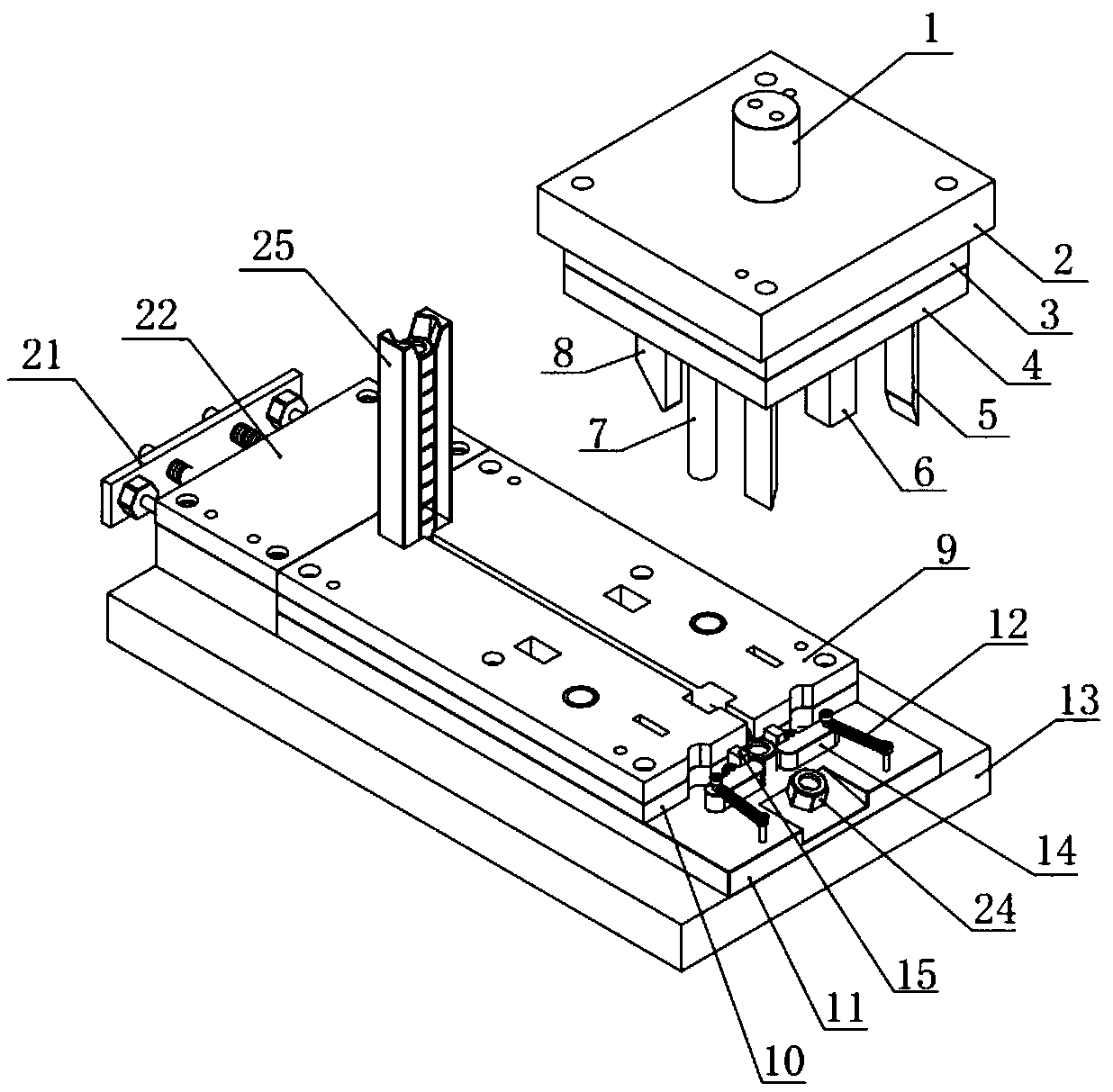

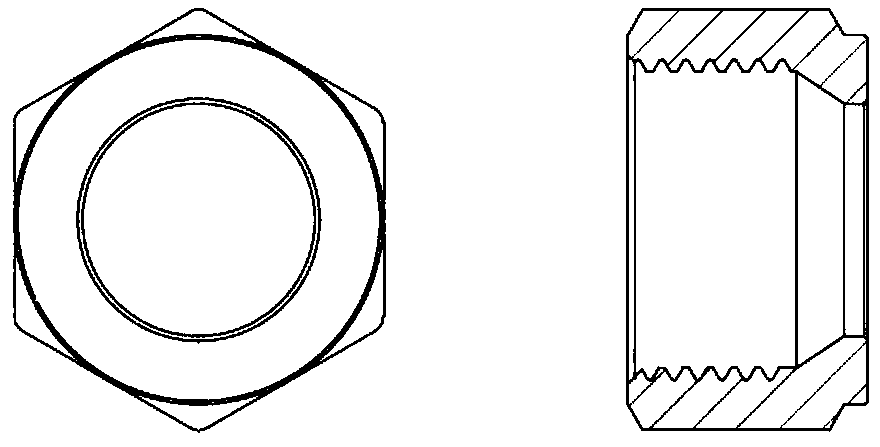

[0034] Such as Figure 1-6 As shown, this embodiment provides a nut automatic feeding marking mold including: upper mold base 2, clamping wedge 5, marking punch 6, long guide post 7, retracting wedge 8, positioning block 10, slide plate 11 , Lower mold base 13, clamping block 16, rear push rod 17, sliding push block 18, side sliding block 19, rear baffle plate 21, linear spring 23, material r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com