Crank and sliding block-based train decoupling equipment

A crank slider and train technology, which is applied to railway car body components, railway vehicle coupling accessories, railway couplings, etc., can solve the problems of high work intensity, low reliability, low efficiency, etc., and achieve convenient operation, Strong reliability and high degree of action completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

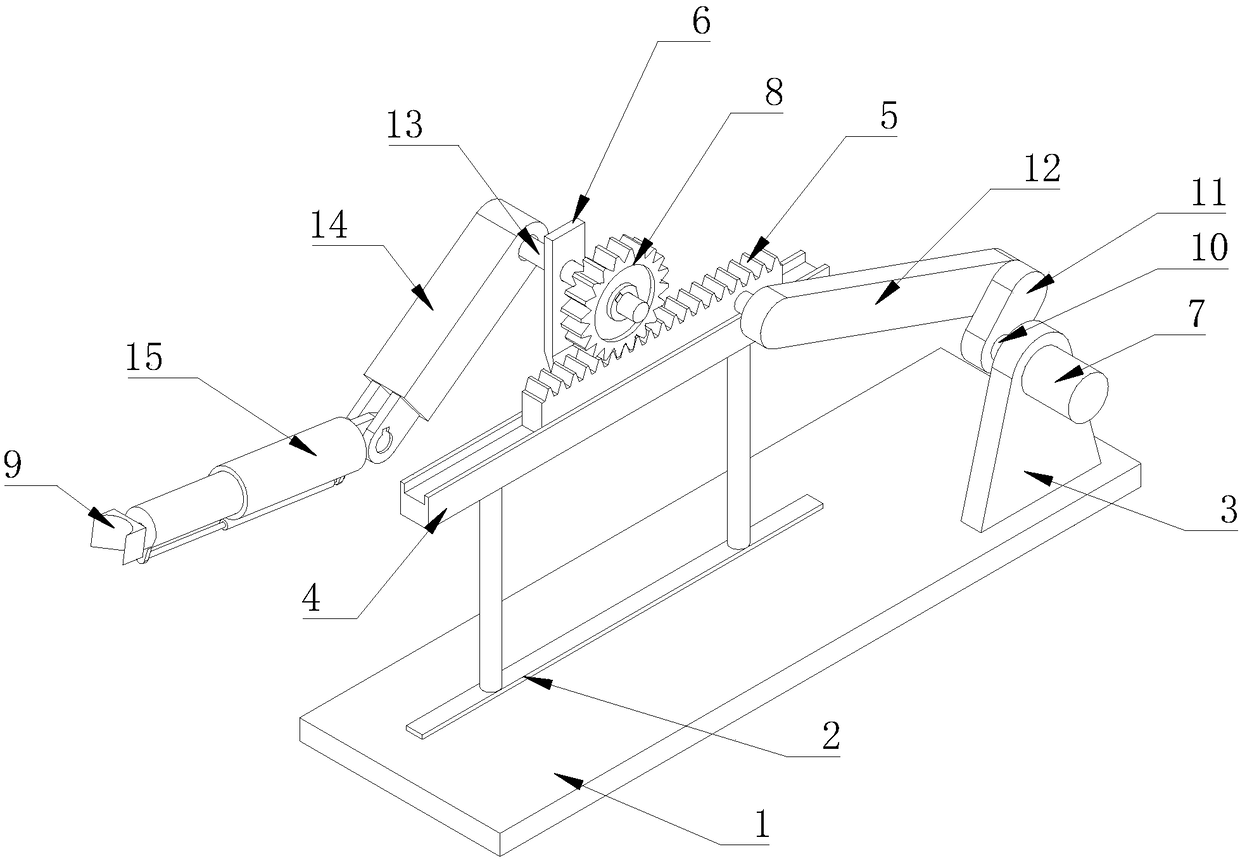

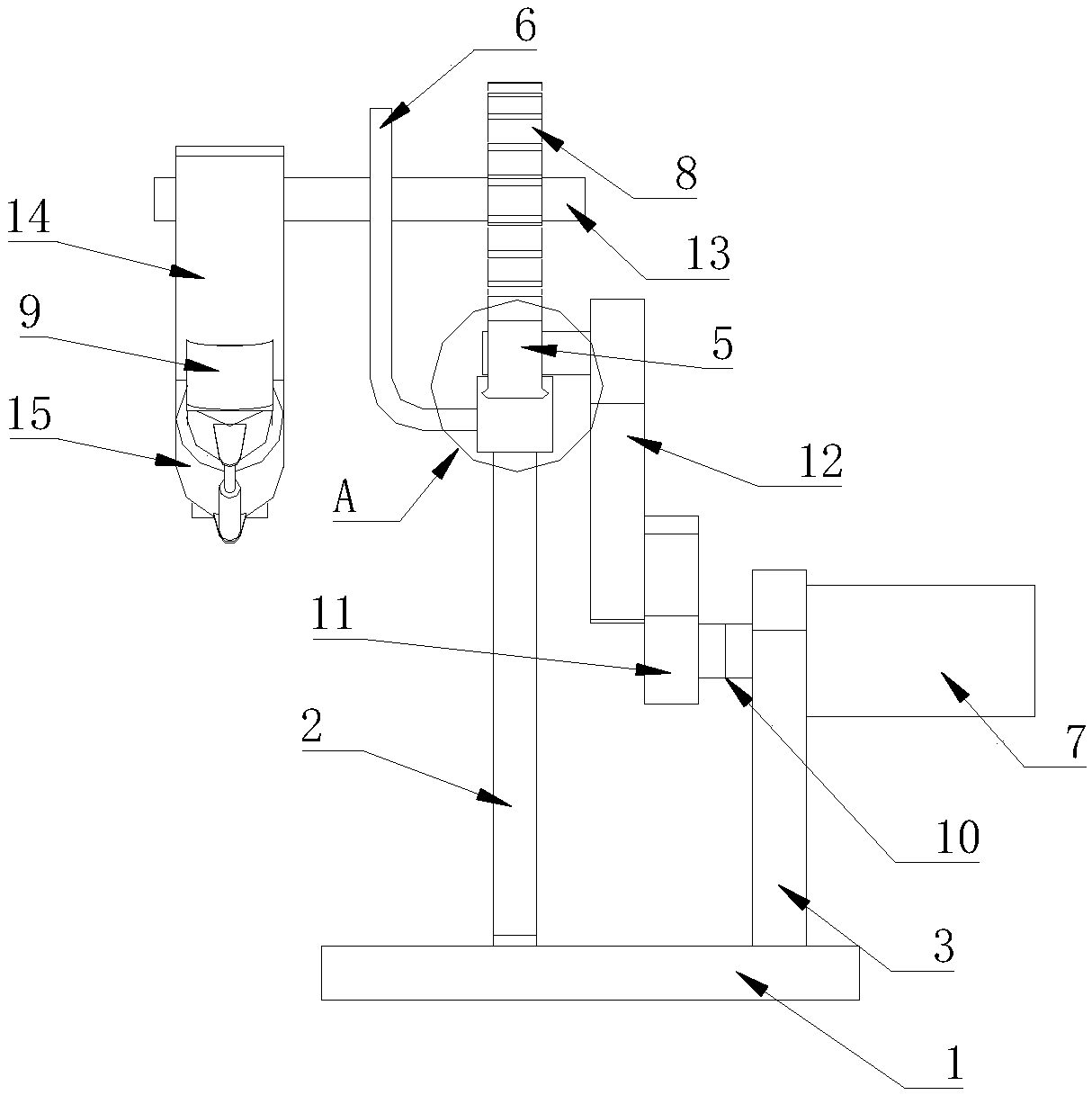

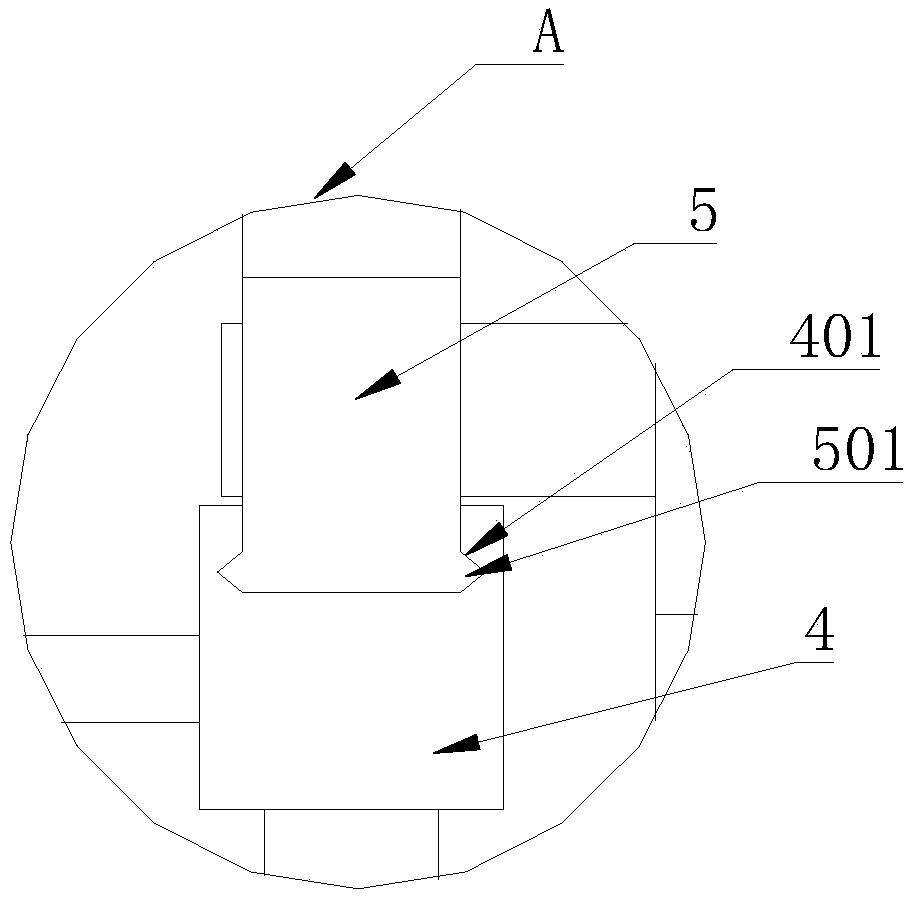

[0026] Please refer to figure 1 , figure 2 and image 3 , the present invention provides a train decoupling device based on a crank slider, comprising a base 1, a bracket 2 and a fixed support plate 3, the bracket 2 can be two poles arranged parallel to the length direction of the base 1, and the The fixed support plate 3 and the support 2 are all vertically fixed on the base 1, and a horizontal chute 4 is fixed on the top of the support 2, and a tooth along the length direction is respectively provided on both sides of the horizontal chute 4. Tooth groove 401, a slidable rack 5 is installed in the horizontal chute 4, a pair of teeth 501 that can be engaged with the tooth groove 401 are provided at the bottom of the rack 5, and the tooth rack 5 can use teeth The movement of 501 in the tooth groove 401 realizes the movement in the horizontal chute 4 without breaking away from the horizontal chute 4; a fixed frame 6 is fixed on the side of the horizontal chute 4 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com