Rigid parachute bag

A technology of drag parachute and umbrella bag, which is applied in the direction of parachute, transportation and packaging, emergency equipment, etc. It can solve the problems that affect the installation of drag parachute, grounding for maintenance, and the inability to arrange the umbrella sleeves side by side closely, so as to improve the utilization rate of aircraft space , Easy to use and maintain, and simplify the structure design of the aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

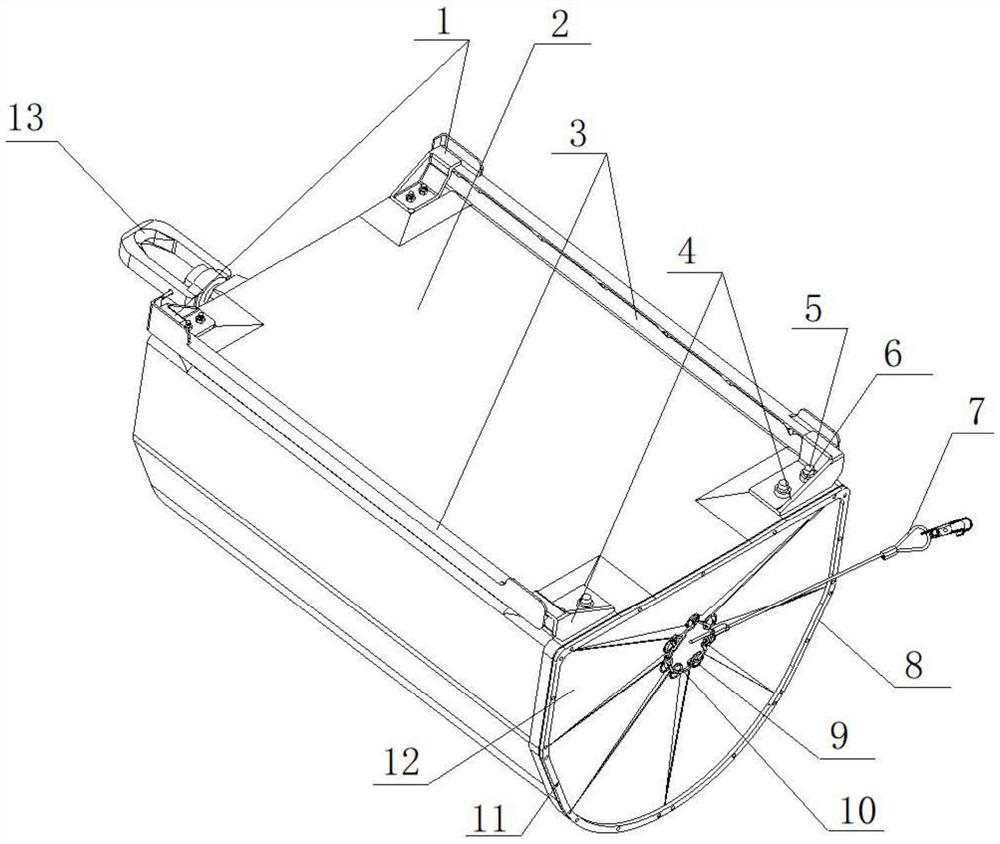

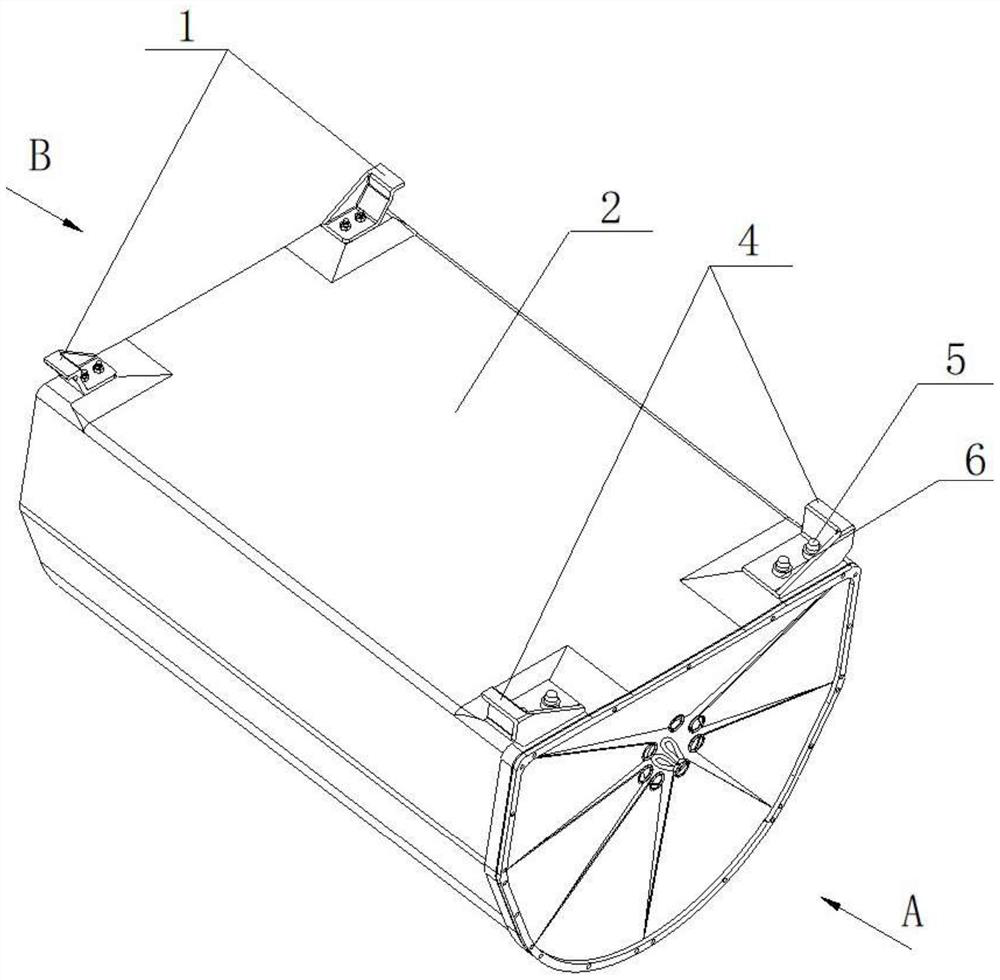

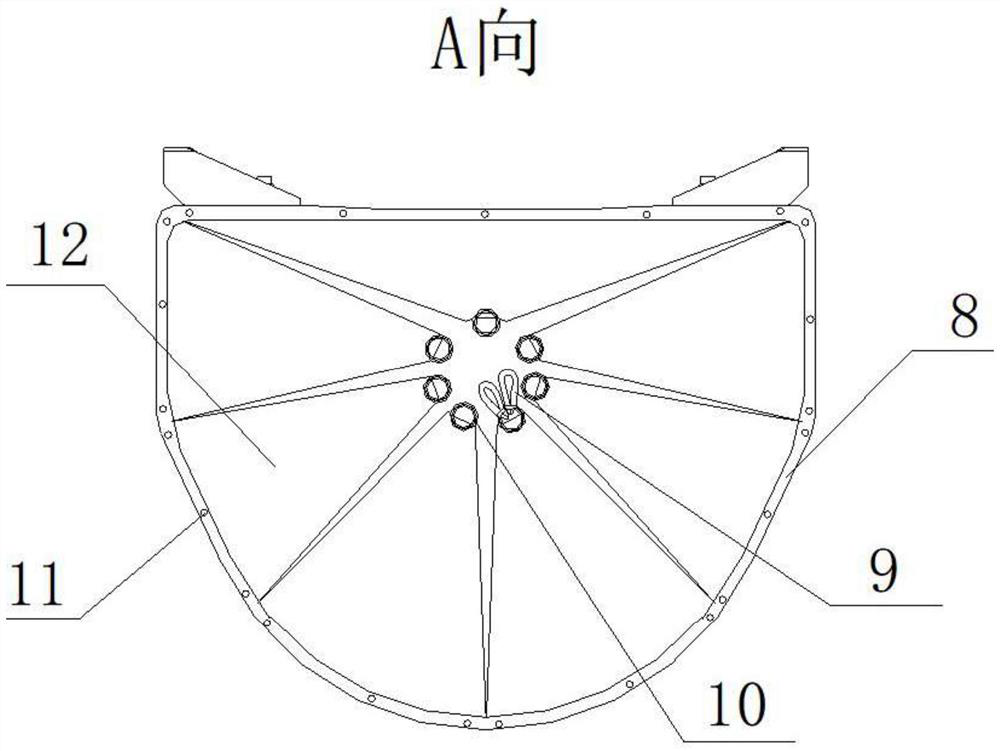

[0019] Such as Figure 1 to Figure 4 As shown, a hard type resistance parachute umbrella bag includes a hard cylinder body 2, the top of the cylinder body 2 is slidably hung on the sky rail 3 in the umbrella cabin, and the front end surface of the cylinder body 2 is provided with a connection for passing through the resistance parachute. The through hole of the hanging ring 13 (detachment when the parachute is convenient), the rear end surface of the cylinder body 2 is an opening and the opening is sealed by the bag buckle 10, the bag pull cord 7 and several soft bag blades 12, and the root of the bag blade 12 is fixed on the opening The edge and movable end are provided with rings 9, and one end of the package drawstring 7 is provided with pins, and the other end is provided with elastic buckles; Insert, and the elastic clasp is hung on the umbrella d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com