Magnesite Gazebo

A magnesite pavilion and magnesia cement technology, which are applied to buildings, small buildings, special buildings, etc., can solve the problems of heavy weight and high preparation cost, and achieve convenient demoulding operation, high preparation efficiency, and improved preparation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

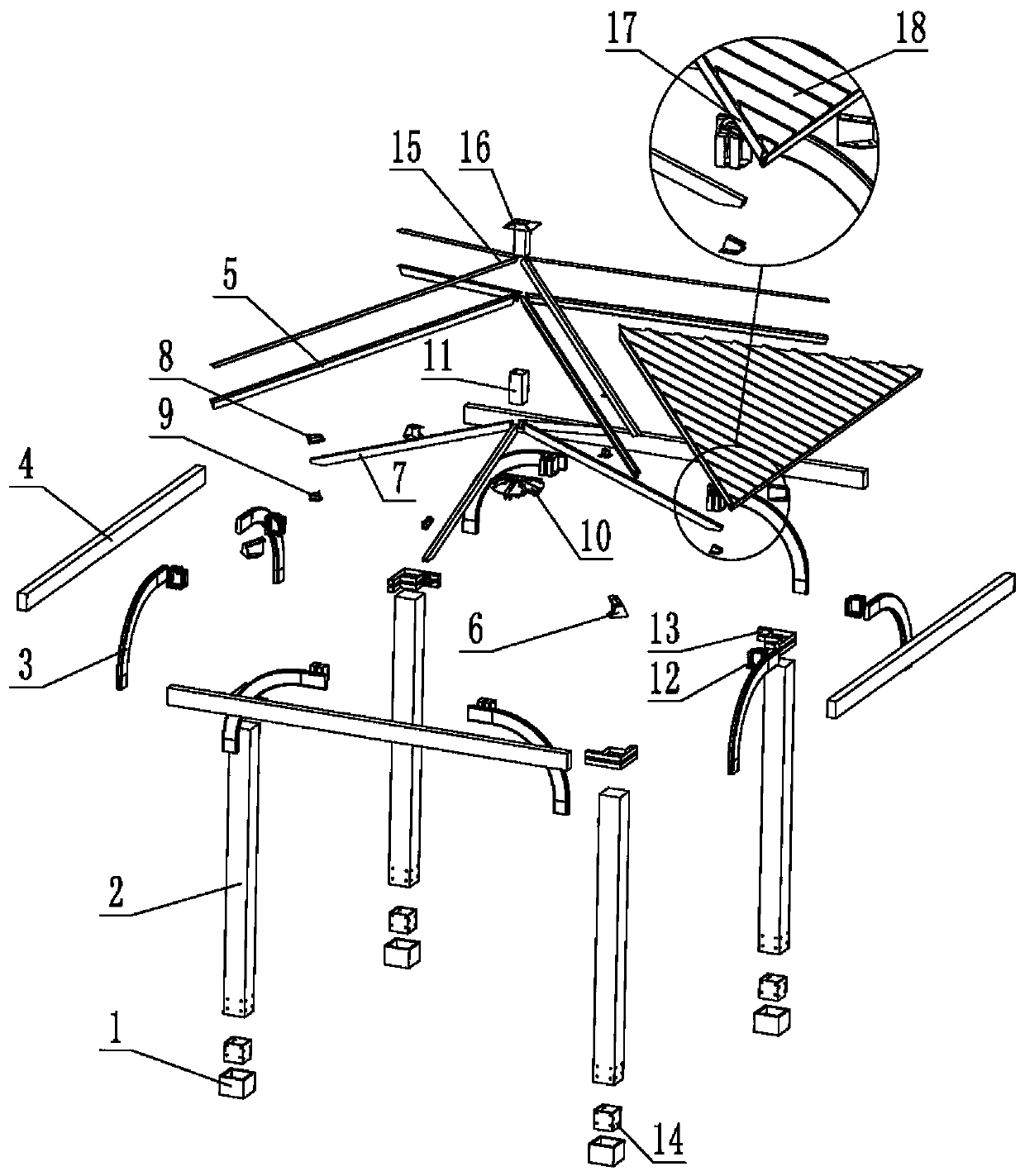

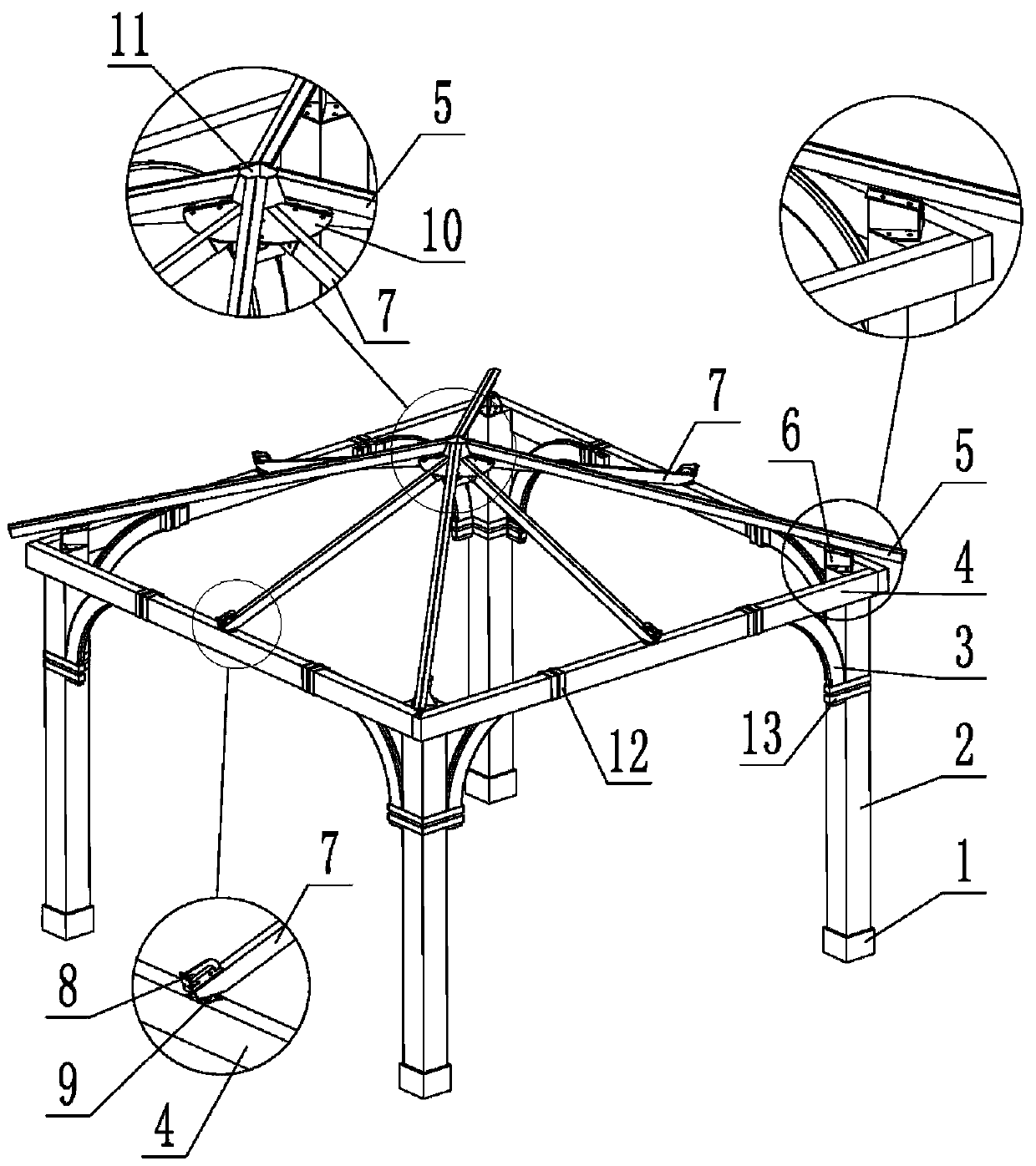

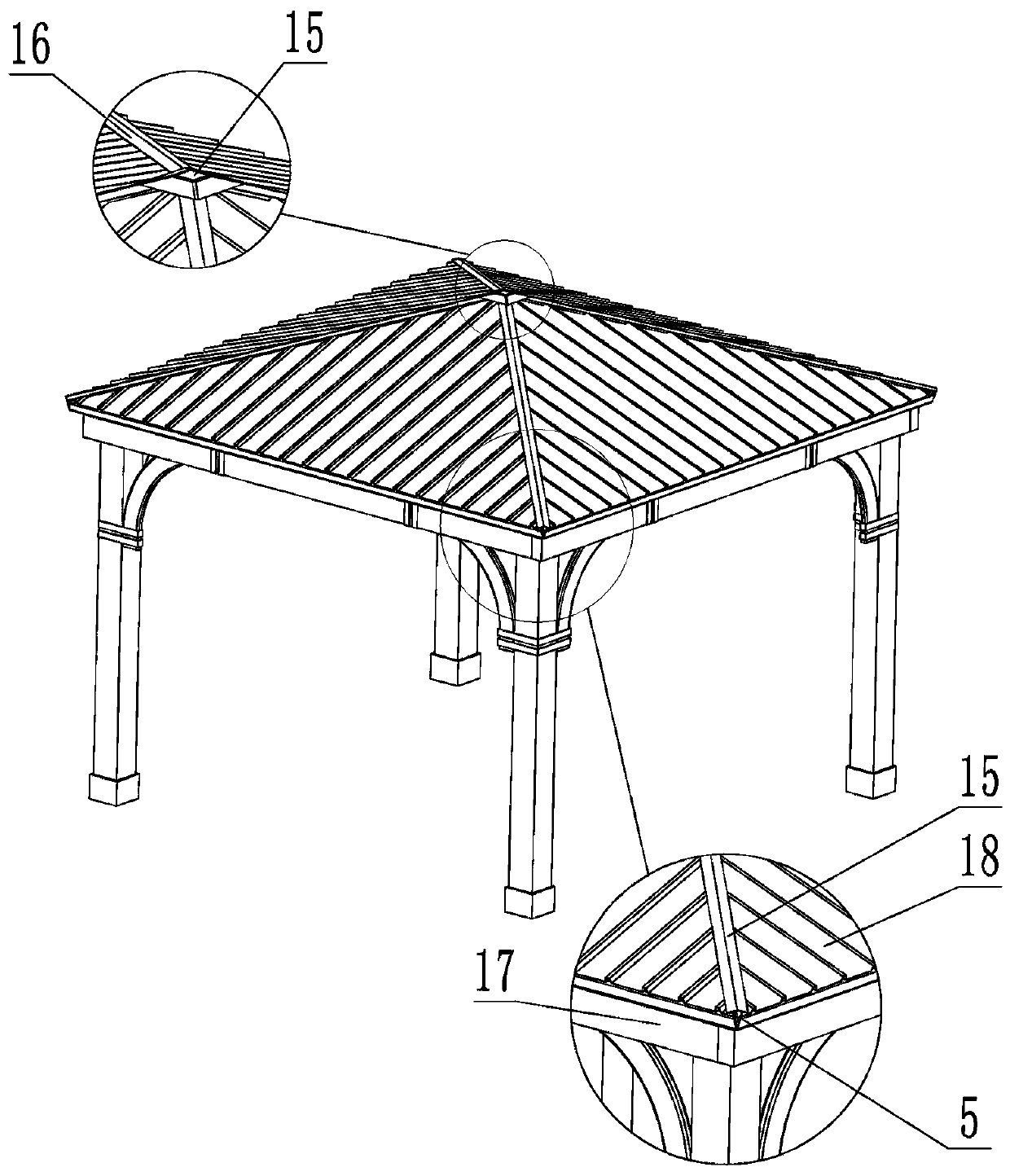

[0054] Its preparation method comprises the following steps:

[0055] Step 1) Prefabricate the fiberglass mesh, cut the aluminum plate to make the room panel, make the column or beam mold or the roof beam mold, the corner connector mold, make four foot linings or / and four jackets or / and eight seals with stainless steel Strips or / and central square tubes or / and four sealing covers or / and roof covers or / and eight central connectors or / and beam iron hoops or / and column iron hoops;

[0056] The column or beam mold or roof beam mold includes side panels I and II oppositely arranged, a bottom panel between side panel I 21 and side panel II 23 and an L-shaped top panel 24 . Between the side plate I and the bottom plate, between the side plate II and the bottom plate, between the L-shaped top plate and the side plate II, there are respectively a pair of corner fittings I 19 and corner fittings II 20 that cooperate with each other and are relatively rotatable. The side plate I, the bo...

Embodiment 2

[0071] In step c) of step 2), 0.2 kg of glass fiber filaments of 5-8 mm, 0.5 kg of sodium carboxymethyl cellulose, and 0.2 kg of sawdust, and 0.3 kg of 20-mesh crushed rice husks were replaced by 0.4 kg of crushed reeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com