User-defined printing device

A custom and printing technology, applied in printing, printing machines, transfer printing, etc., can solve the problems affecting the aesthetics of clothing and changes in the shape of clothing, and achieve the effect of satisfying randomness and maintaining aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

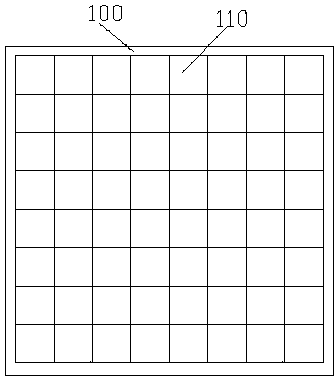

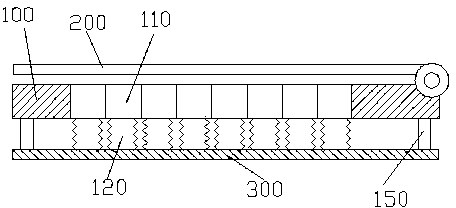

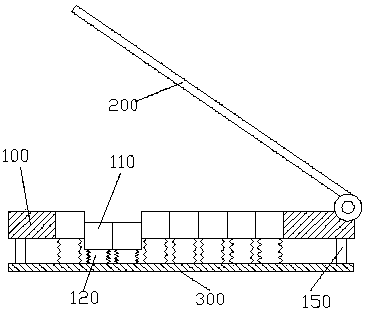

[0015] refer to figure 1 , figure 2 , in this embodiment, the custom printing device includes an upper platen 200 and a lower platen 100, the upper platen 200 is a touch screen, the touch screen 200 is hinged to one side of the lower platen 100, and the lower platen 100 includes a row Square pressing blocks 110 in a rectangular array and a rectangular frame for accommodating the rectangular array, the square pressing blocks 110 are movably connected to each other, that is, the square pressing blocks 110 can move up and down on the plane of the lower pressing plate 100, The bottom of the lower platen 100 is fixed with a base plate 300 through the column 150, and the air column 120 corresponding to the square briquetting block 110 is evenly distributed on the base plate 300, and the air column 120 is connected to the corresponding square briquetting block 110. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com