Blast-furnace hot blast stove pressure-stabilizing stove changing system applied to metallurgy

A technology of hot blast stove and blast furnace, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc. It can solve the problems of blast furnace slippage and wind pressure fluctuation, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

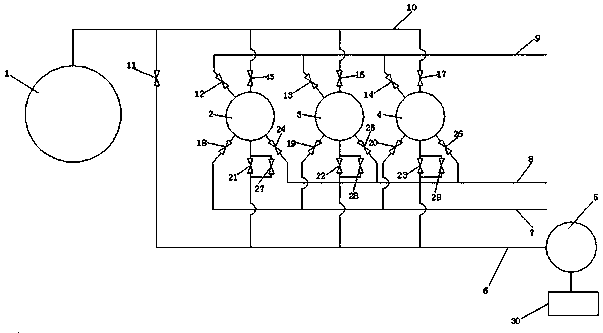

[0023] Such as figure 1 as shown in figure 1 As shown, a blast furnace hot blast stove voltage stabilization system applied to metallurgy includes blast furnace 1, first hot blast stove 2, second hot blast stove 3, third hot blast stove 4, main fan 5, air delivery pipe 6, combustion air Pipe 7, gas pipe 8, waste gas pipe 9, hot blast pipe 10 and controller 30, the main fan 5 is respectively connected with the first hot blast stove 2, the second hot blast stove 3, the third hot blast stove 4 and the hot blast through the air delivery pipe 6 Tube 10 communicates. The combustion air pipes 7 communicate with the first hot blast stove 2 , the second hot blast stove 3 and the third hot blast stove 4 respectively. The gas pipes 8 communicate with the first hot blast stove 2 , the second hot blast stove 3 and the third hot blast stove 4 respectively. The waste gas pipe 9 communicates with the first hot blast stove 2 , the second hot blast stove 3 and the third hot blast stove 4 res...

Embodiment 2

[0026] Based on Embodiment 1, a control valve 11 is provided at the connection between the air delivery pipe 6 and the hot air pipe 10 .

[0027] In use, through the set control valve, the controller can control the opening and closing of the control valve, so as to adjust the air volume from the air delivery pipe into the hot air pipe, so as to stabilize the furnace pressure.

Embodiment 3

[0029] Based on Embodiment 2, a first cold air valve 21 is provided at the connection between the air delivery pipe 6 and the first hot blast stove 2, and a first pressure equalizing valve 27 is connected in parallel on the first cold air valve 21, and the air delivery pipe 6 and the second hot blast stove 3. A second cold air valve 22 is provided at the connection, and a second pressure equalizing valve 28 is connected in parallel to the second cold air valve 22. A third cold air valve 23 is provided at the connection between the air delivery pipe 6 and the third hot blast stove 4, and the third A third pressure equalizing valve 29 is connected in parallel with the cold air valve 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com