Method for Electromodifying Lithium Titanate in Molten Salt

A technology of lithium titanate and molten salt, applied in the direction of electrolytic components, electrolytic process, etc., to achieve the effect of reducing size, improving electrochemical performance, and improving battery uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

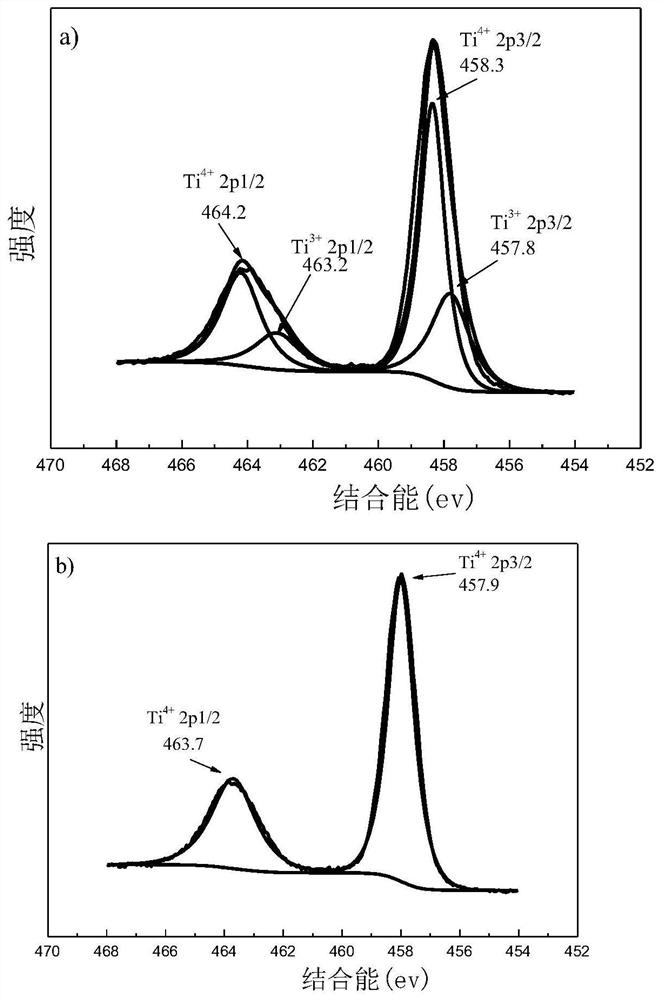

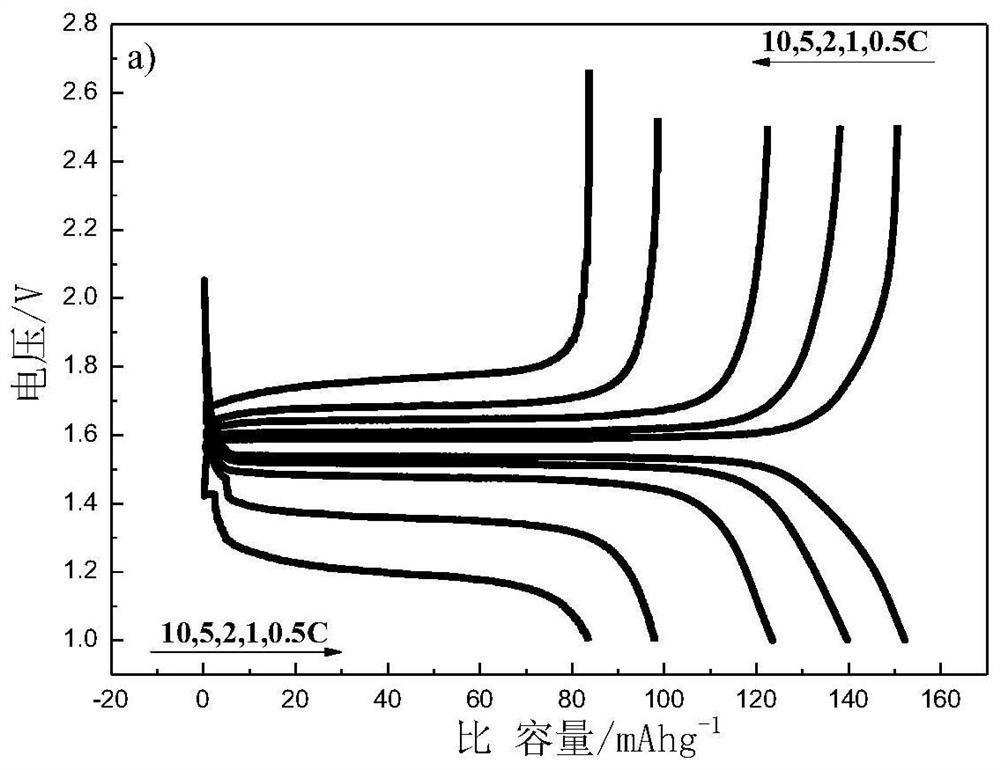

[0031] Weigh 2.93g TiO according to the molar ratio Ti:Li=5:4.5 2 as titanium source and 1.22gLi 2 CO 3 As a lithium source, put it into a mortar and grind it for 10 minutes and mix it evenly, then weigh 10g of NaCl-KCl mixed molten salt with a molar ratio of 1:1, and mix it evenly again with a mortar. Put the mixture of molten salt and precursor into a Ф6cm graphite crucible. In order to carry out the subsequent molten salt electric modification step, a graphite rod is placed on the side wall of the graphite crucible as an electrode, and the entire crucible is placed on a Ф10cm. 1:1 NaCl-KCl mixed molten salt corundum crucible, then put the corundum crucible with graphite crucible into a vertical single temperature zone vacuum atmosphere tube furnace, enter Ar gas as a protective atmosphere, heat treatment at 800 °C 6h.

[0032] After the specified reaction time, the temperature of the furnace body remains unchanged. Under high temperature conditions, a graphite rod is ins...

Embodiment 2

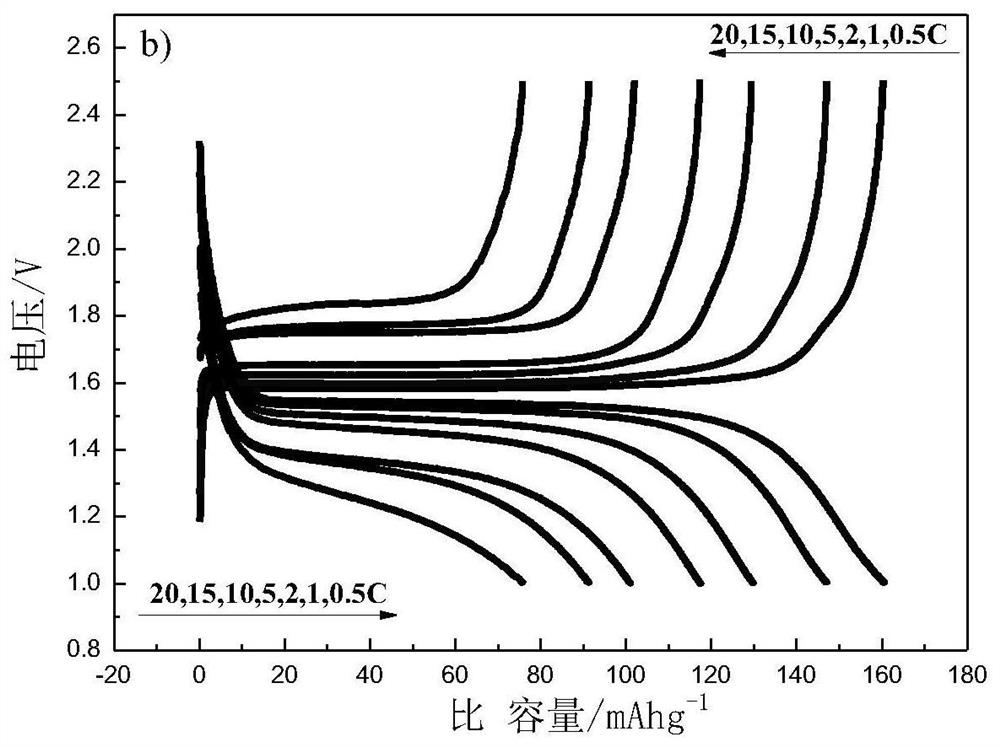

[0035] Weigh 2.93g TiO according to the molar ratio Ti:Li=5:4.5 2 as titanium source and 1.22gLi 2 CO 3 As a lithium source, put it into a mortar and grind it for 10 minutes and mix it evenly, then weigh 10g of NaCl-KCl mixed molten salt with a molar ratio of 1:1, and mix it evenly again with a mortar. Put the mixture of molten salt and precursor into a Ф6cm graphite crucible. In order to carry out the subsequent molten salt electric modification step, a graphite rod is placed on the side wall of the graphite crucible as an electrode, and the entire crucible is placed on a Ф10cm. 1:1 NaCl-KCl mixed molten salt in a corundum crucible, then put the corundum crucible with graphite crucible into a vertical single temperature zone vacuum atmosphere tube furnace, pass in Ar gas as a protective atmosphere, heat treatment at 850°C 4h.

[0036] After the specified reaction time, the temperature of the furnace body remains unchanged. Under high temperature conditions, a graphite rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com