Advanced monitoring and early warning device and construction method for leakage of concrete construction joints in underground structures

An underground structure, monitoring and early warning technology, applied in the direction of basic structure engineering, protection devices, basic structure tests, etc., can solve the problems of weakened structural anti-seepage performance, anti-seepage and anti-leakage reactions, hidden risks, etc., to achieve long service period, Small influence, effect of improving impermeability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the invention will be further described below in conjunction with the accompanying drawings.

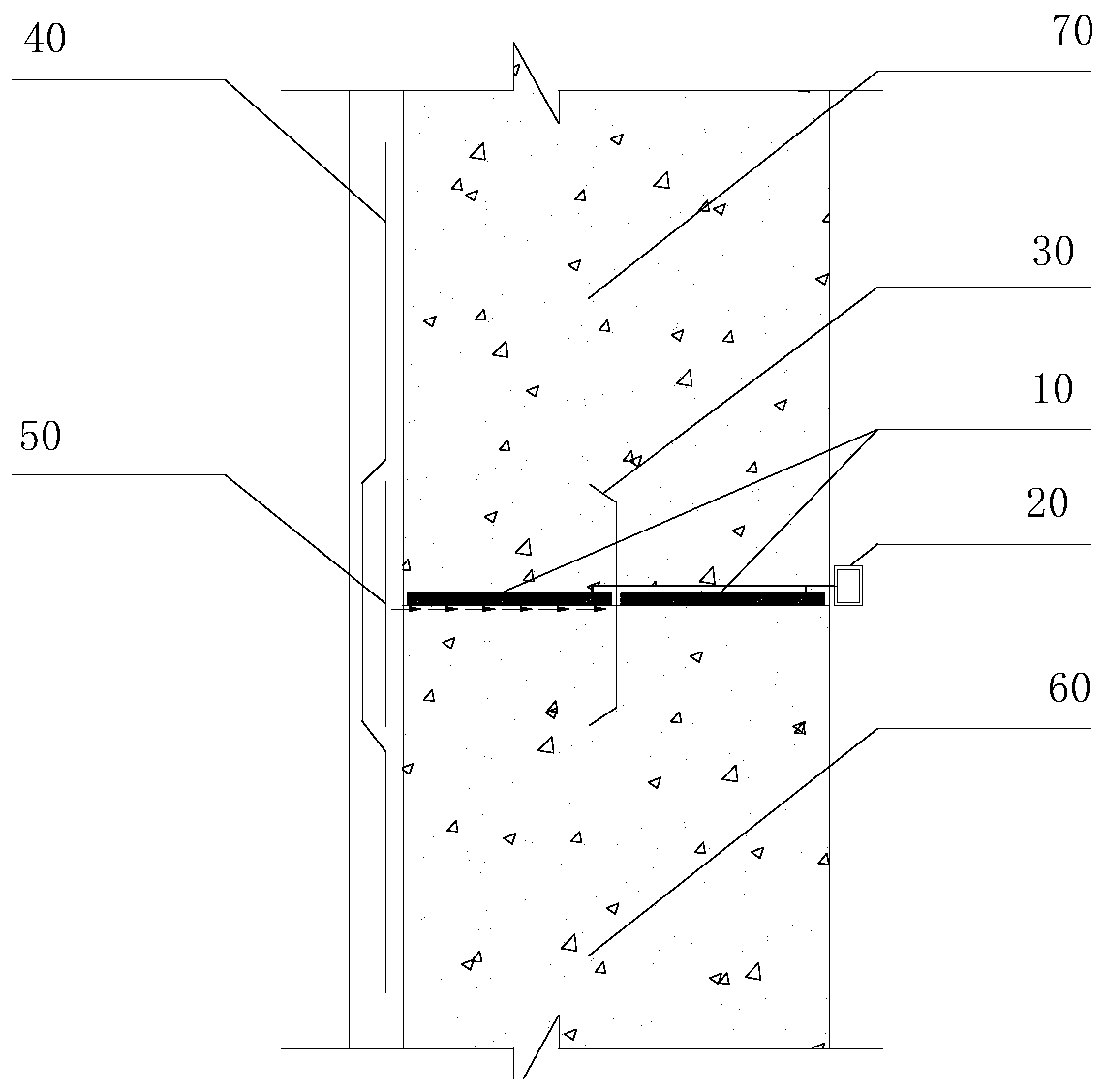

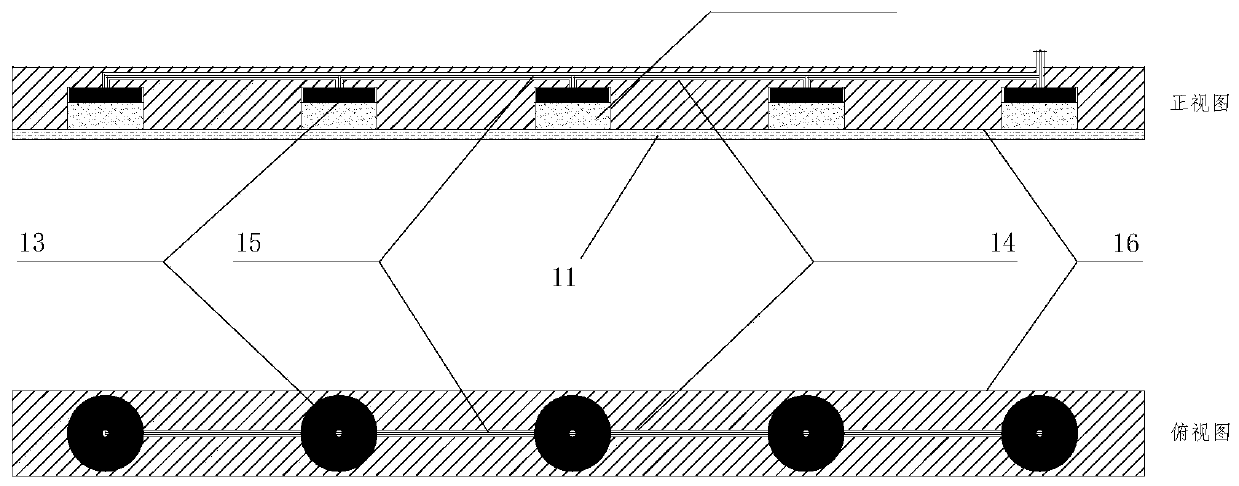

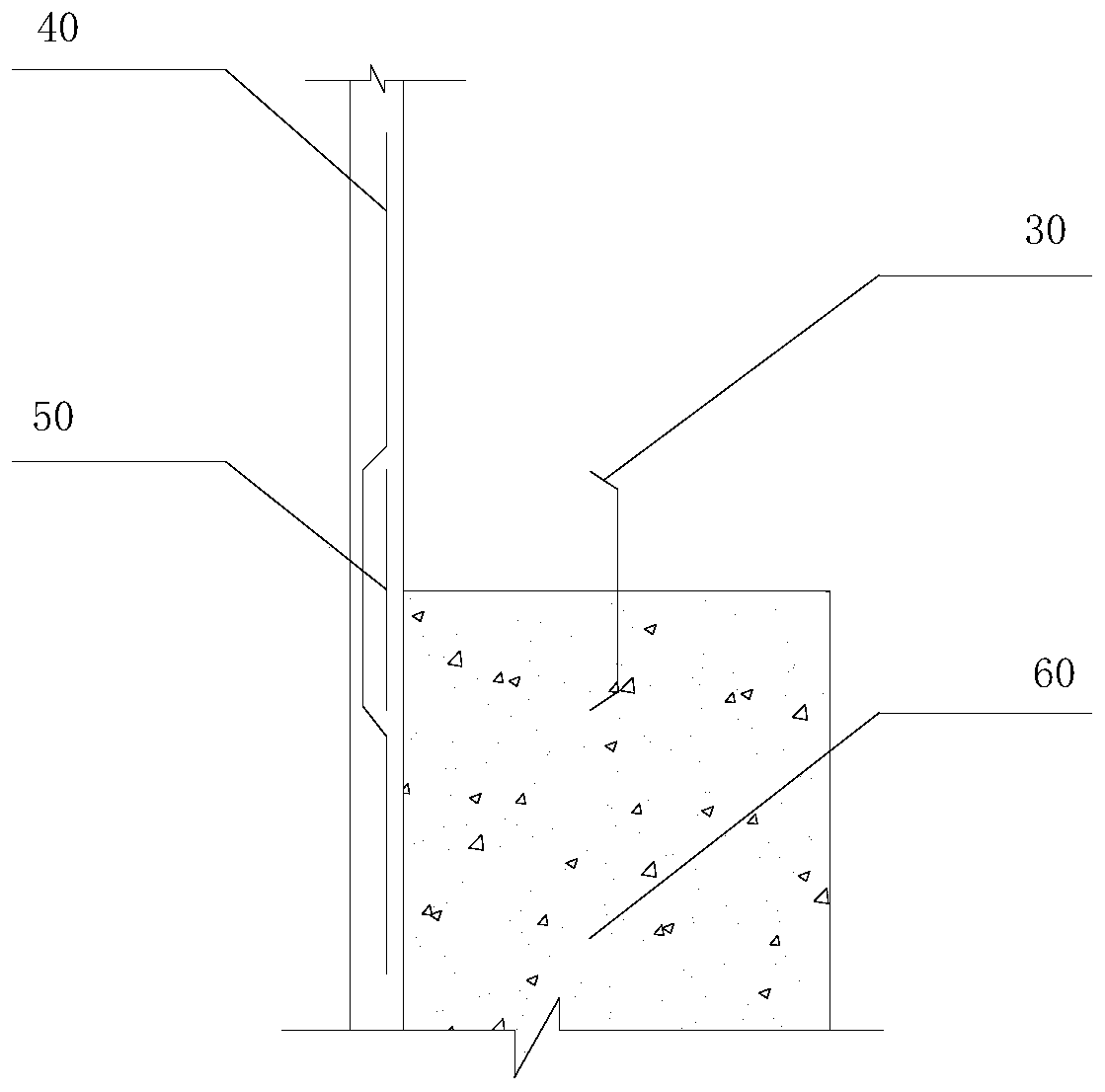

[0036] Such as figure 1 and figure 2 As shown, a kind of underground structure concrete construction joint leakage advanced monitoring and early warning device, including detection device 10, data acquisition instrument 20, computer terminal; further as figure 2 As shown, the detection device 10 includes a moisture-proof layer 11, a water-swellable rubber 12, a miniature pressure box 13, a pressure box lead pipe 14, a pressure box lead 15, and a steel shell 16; the water-swellable rubber 12 is arranged on the moisture-proof layer 11, And the bottom of the water-swellable rubber 12 is closely attached to the moisture-proof layer 11, the top of the water-swellable rubber 12 is closely attached to the miniature pressure box 13, and the volume of the water-swellable rubber 12 will expand when encountering leakage water, and then the micro-pressure box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com