Aircraft fuel oil conveying structure

A technology for aircraft and fuel, which is applied in the direction of turbine/propulsion fuel delivery system, fuel tank of power plant, engine components, etc. It can solve the problems of airborne equipment accessibility restrictions, connection joint leakage, limited space, etc., and achieve installation and maintenance Increased space, simple fuel system, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

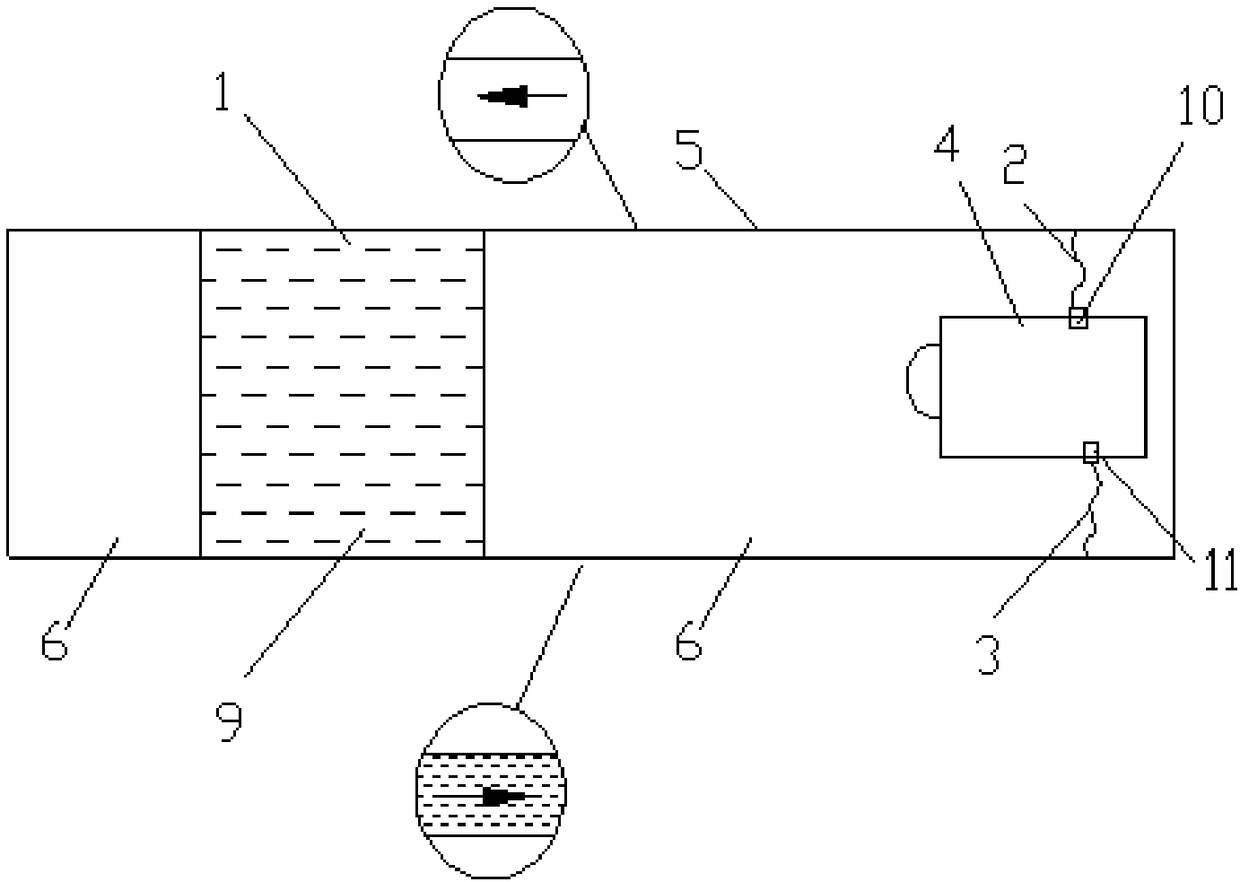

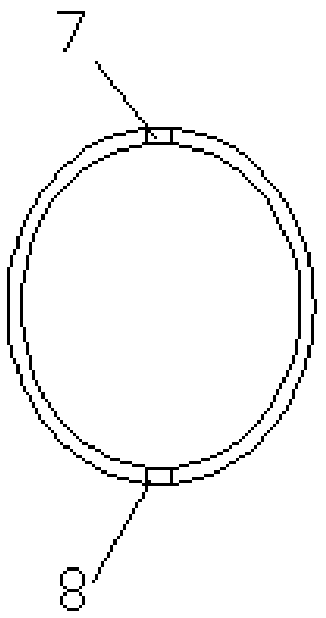

[0019] Such as figure 1 As shown, the top of the aircraft body structure 5 is provided with a first passage 7, and one end of the first passage 7 communicates with the hose I2, and the hose I2 communicates with the engine gas outlet 10; the other end of the first passage 7 communicates with the fuel tank compartment 1 connected at the top.

[0020] The bottom of the aircraft body structure 5 is provided with a second passage 8, and one end of the second passage 8 communicates with the hose 3, and the hose II 3 communicates with the engine fuel inlet 11; the other end of the second passage 8 communicates with the bottom of the fuel tank compartment 1 .

[0021] The engine pressurized gas enters the hose I2 from the engine gas outlet 10, then enters the first channel 7, and enters the top of the fuel tank compartment 1 along this channel, and then, the fuel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com