Exhausting back pressure valve

A technology of exhaust back pressure and valve body, applied in the direction of exhaust device, muffler device, engine components, etc., can solve problems such as failure of back pressure valve, and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

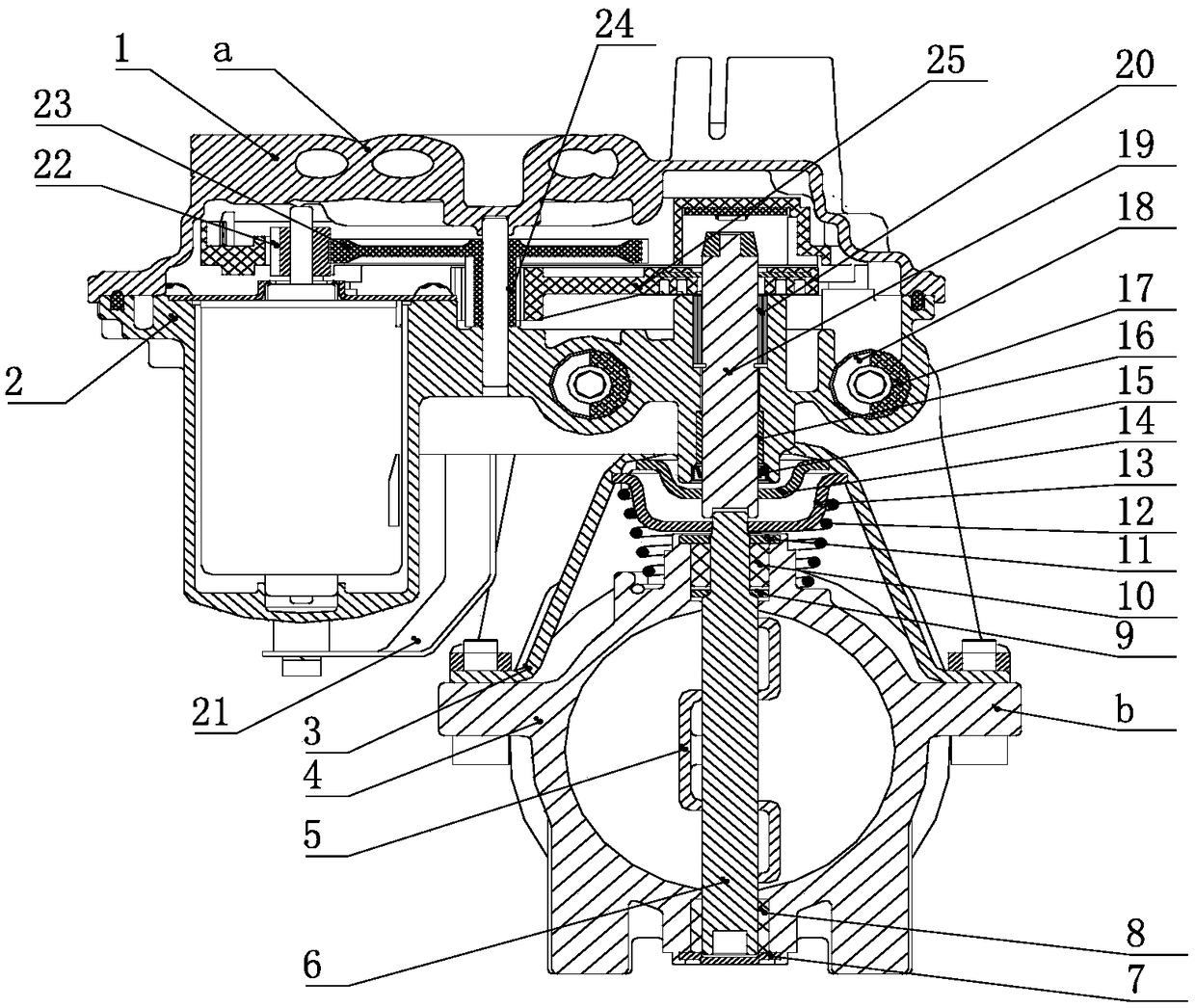

[0033] This embodiment provides an exhaust back pressure valve, which includes a motor control assembly, a valve body assembly, and a bracket connecting the motor control assembly and the valve body assembly.

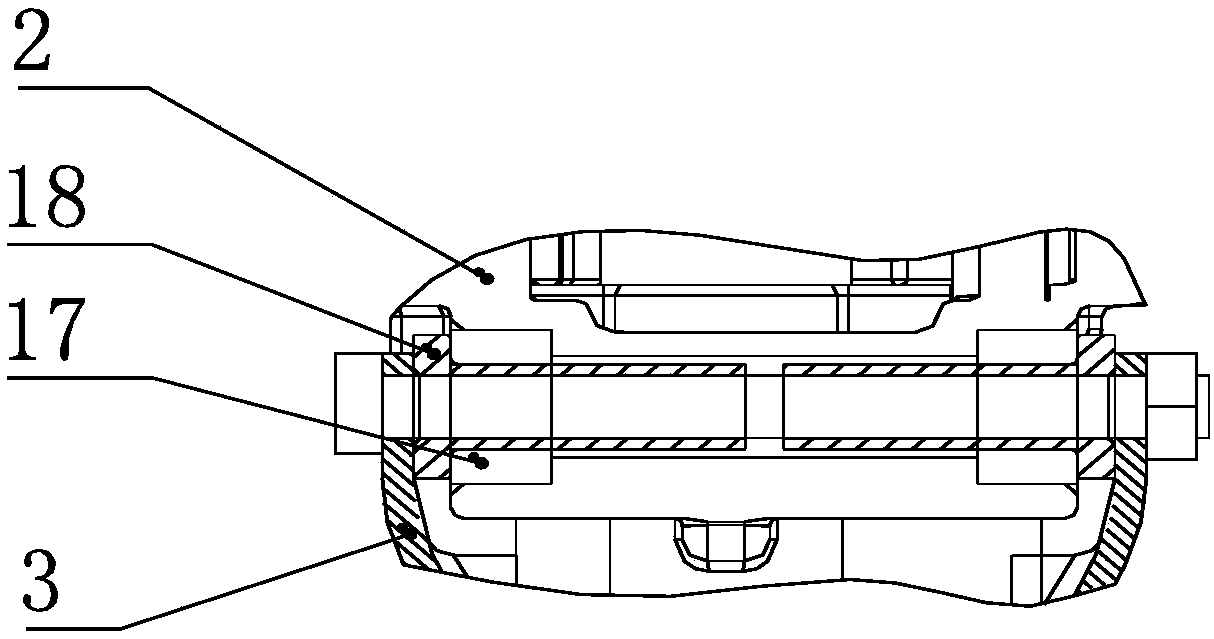

[0034] Wherein, the motor control assembly includes an upper casing 1 and a lower casing 2, and an accommodation cavity is formed between the upper casing 1 and the lower casing 2, and a motor and a reducer are arranged in the accommodation cavity. In this embodiment , the motor is arranged in the cavity formed by the lower housing 2; the reducer includes a first driving gear, a first driven gear, a second driving wheel, a second driven wheel, an intermediate shaft and an output shaft .

[0035] The output shaft of the motor is coaxially fixed with a first driving gear; the first driven gear is rotatably arranged on the intermediate shaft and meshes with the first driving gear; the second driving gear The wheel is rotatably arranged on the intermediate shaft, and is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com