Defrosting system and defrosting control method of air conditioner, and air conditioner

A control method and technology for an air conditioner, which are applied in the directions of control input involving air characteristics, space heating and ventilation control input, space heating and ventilation, etc., can solve the problems of high condensation pressure and temperature of the evaporator, and improve user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

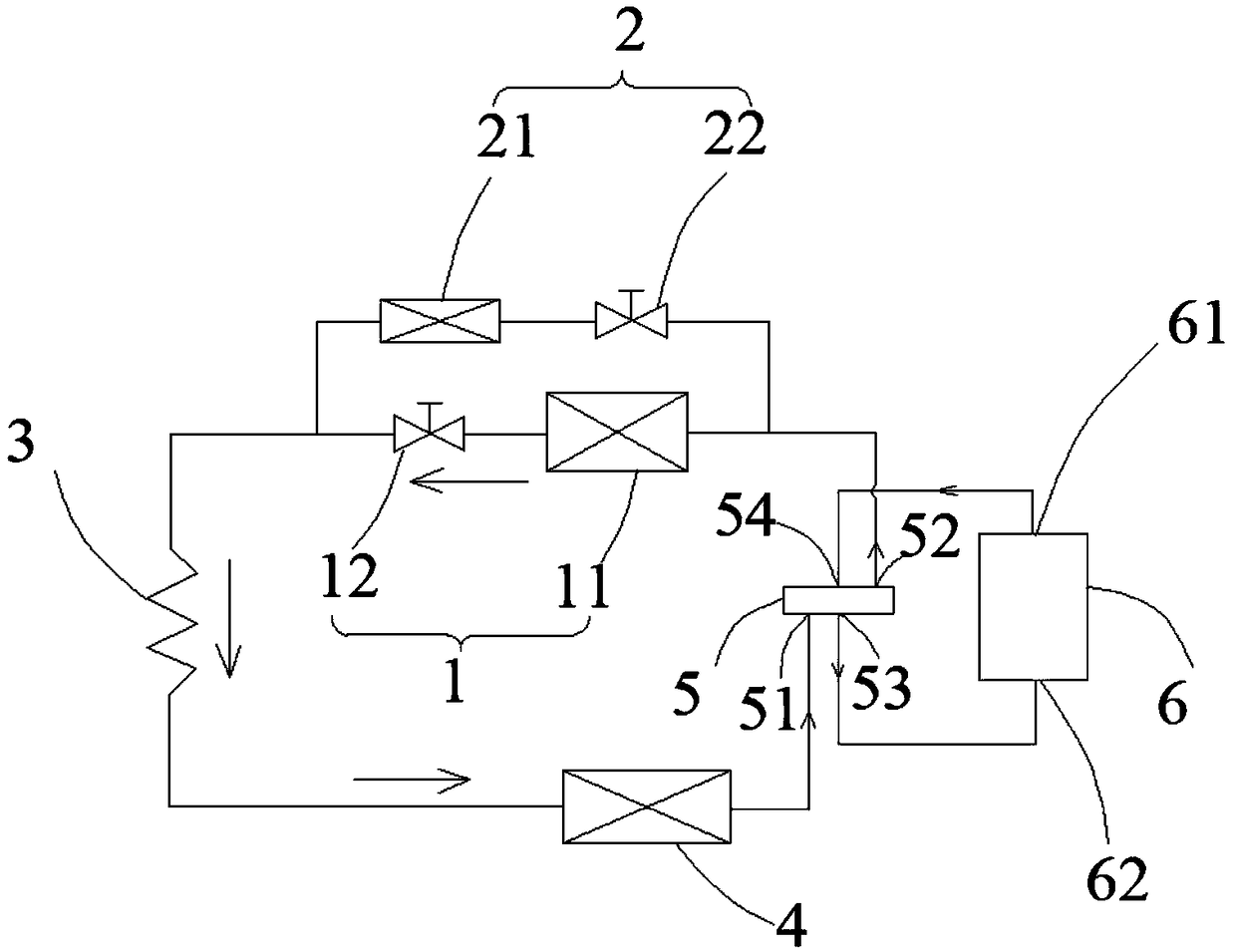

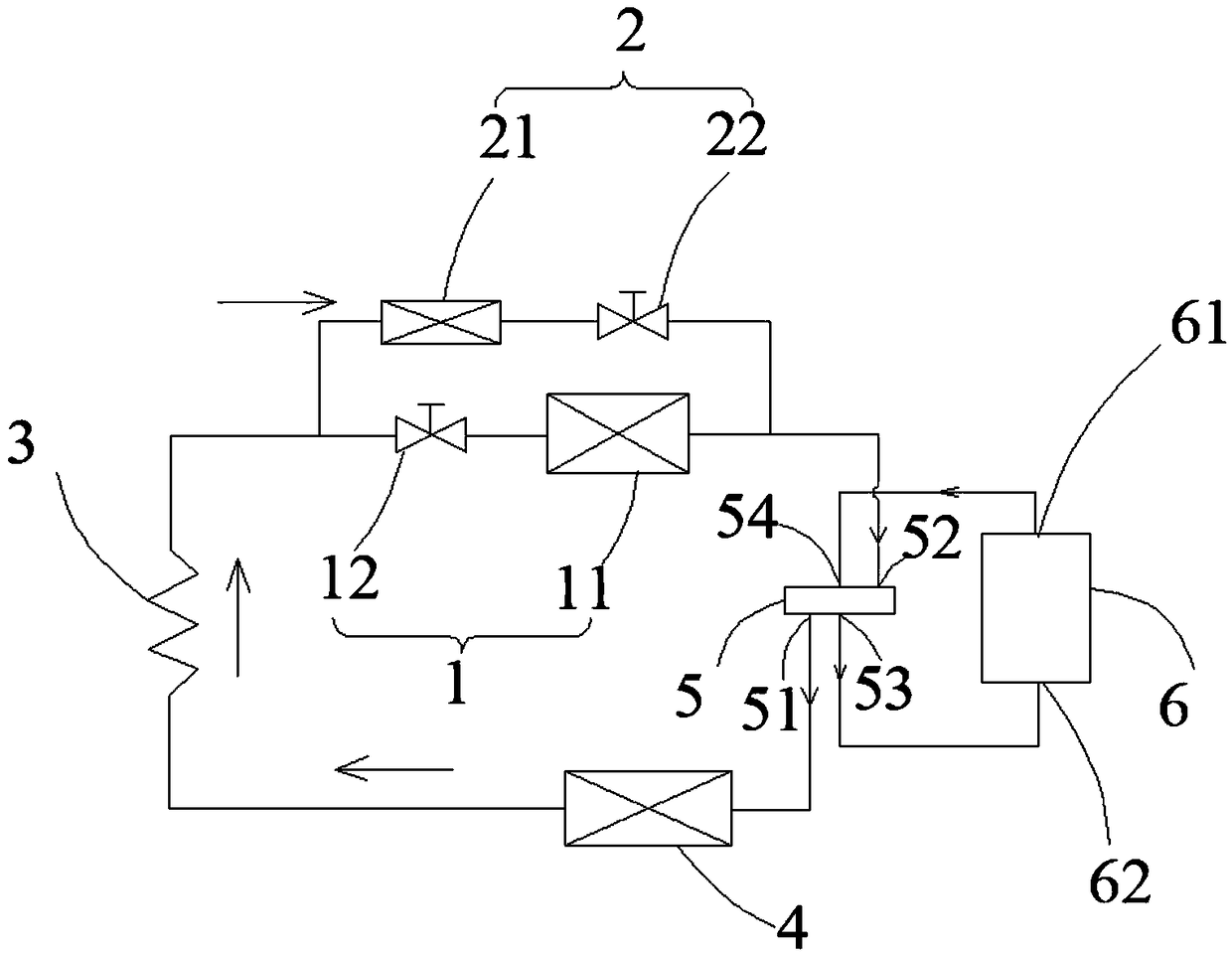

[0043] combine figure 1 with figure 2 As shown, the defrosting system of the air conditioner in this embodiment includes a condensation branch 1 and a defrosting branch 2; the condensation branch 1 is provided with a first condenser 11 and a first solenoid valve 12 connected in series; the defrosting branch Road 2 is provided with a second condenser 21 and a second solenoid valve 22 connected in series; the first solenoid valve 12 is connected to the throttle mechanism 3, the evaporator 4 and the evaporator end 51 of the four-way valve 5 in sequence; the first condenser 11 Connected to the condenser end 52 of the four-way valve 5; the second solenoid valve 22 is connected to the condenser end 52 of the four-way valve 5; the second condenser 21 is connected to the throttle mechanism 3, the evaporator 4 and the four-way valve 5 in sequence Evaporator end 51. Wherein, the throttling mechanism 3 is one of a capillary tube and an electronic expansion valve, and in order to compr...

Embodiment 2

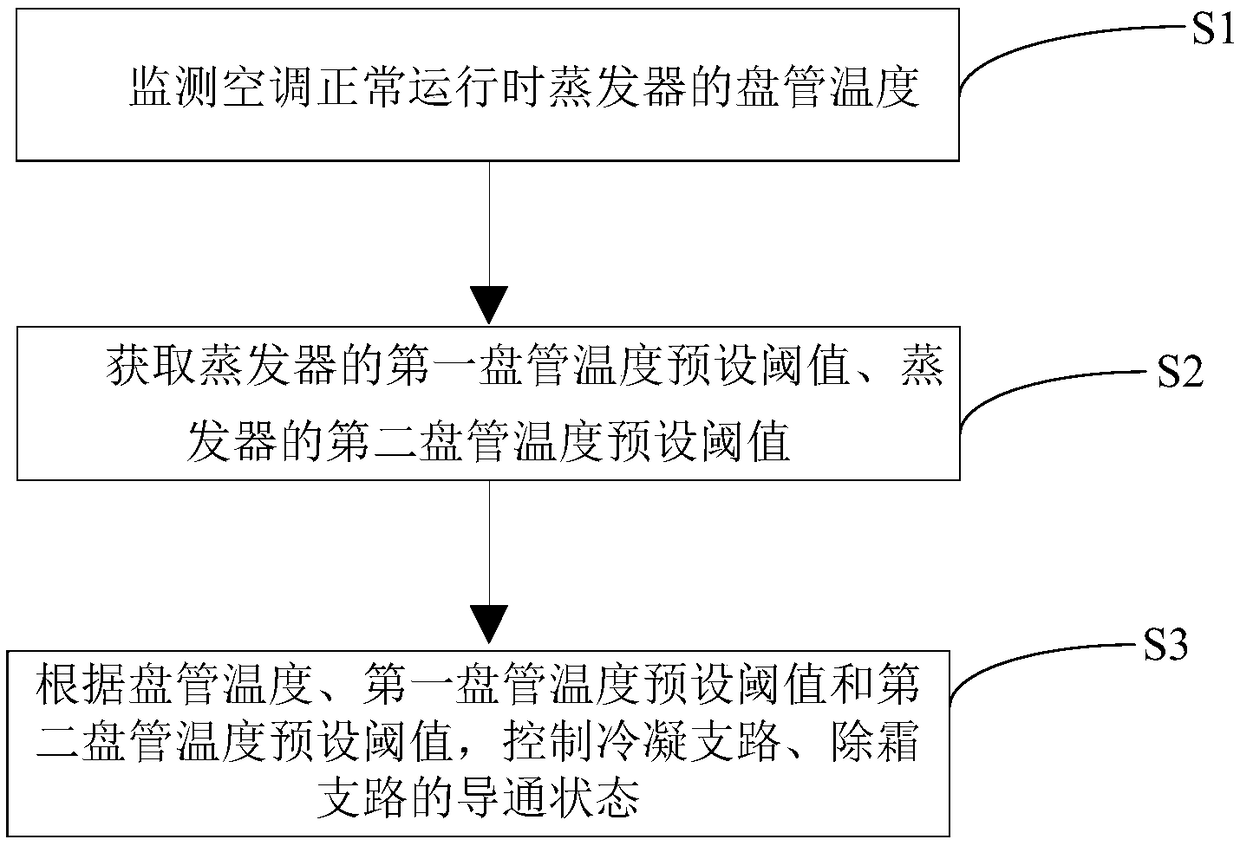

[0052] combine image 3 As shown, a defrosting control method of an air conditioner, wherein the air conditioner includes a condensation branch 1, a defrosting branch 2, wherein the defrosting control method includes:

[0053] S1, monitoring the coil temperature of the evaporator 4 when the air conditioner is in normal operation;

[0054] S2. Obtain the first coil temperature preset threshold of the evaporator 4 and the second coil temperature preset threshold of the evaporator 4;

[0055] S3. Control the conduction states of the condensation branch 1 and the defrosting branch 2 according to the coil temperature, the first coil temperature preset threshold, and the second coil temperature preset threshold.

[0056] The defrosting control method of the air conditioner of the present embodiment uses the coil temperature of the evaporator 4 as the monitoring parameter, because it can intuitively reflect the frosting state of the evaporator 4, so that the defrosting control metho...

Embodiment 3

[0062] An air conditioner, comprising the above-mentioned defrosting system of the air conditioner.

[0063] The air conditioner of this embodiment adopts the above-mentioned defrosting system of the air conditioner, which separates air conditioning refrigeration and defrosting by setting the condensation branch 1 and the defrosting branch 2, and controls the flow rate of the refrigerant in the defrosting branch 2. Defrost, to prevent the defrosting of the condenser in the original condensing system of the air conditioner, because the condenser in the original condensing system is too large, and its heat exchange capacity is large, causing the evaporation pressure on the condenser side to be too high, which in turn leads to evaporator 4 The condensing pressure and temperature on the side of the evaporator are too high, resulting in high pressure protection, and avoid the high temperature on the 4 side of the evaporator, which will cause the temperature inside the evaporator to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com