Proximity sensor

A technology of proximity sensors and potentiometers, applied in the field of proximity sensors, can solve problems such as low production efficiency, poor reliability, and cumbersome production processes, and achieve the effects of improving measurement accuracy, stability, and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

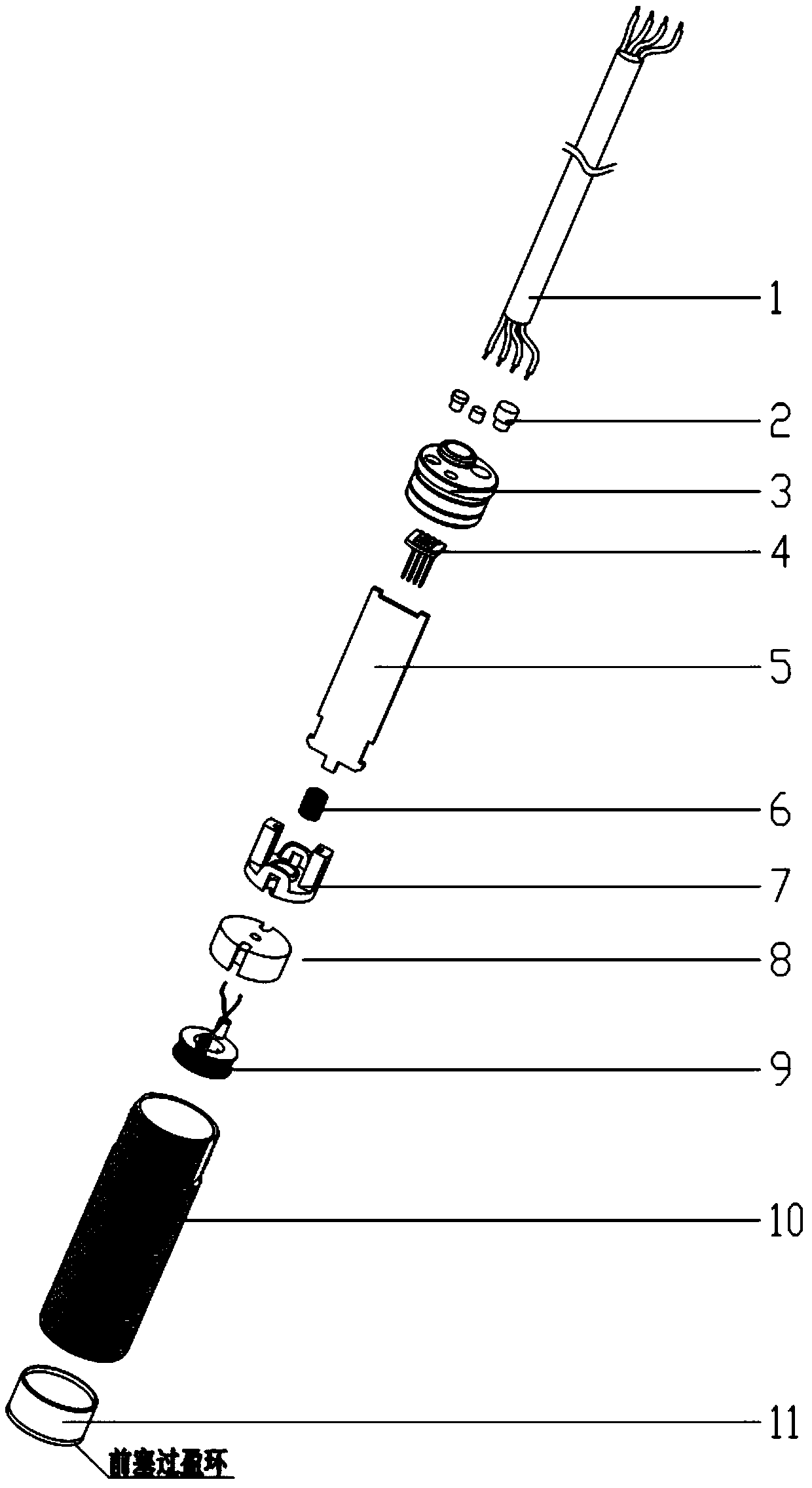

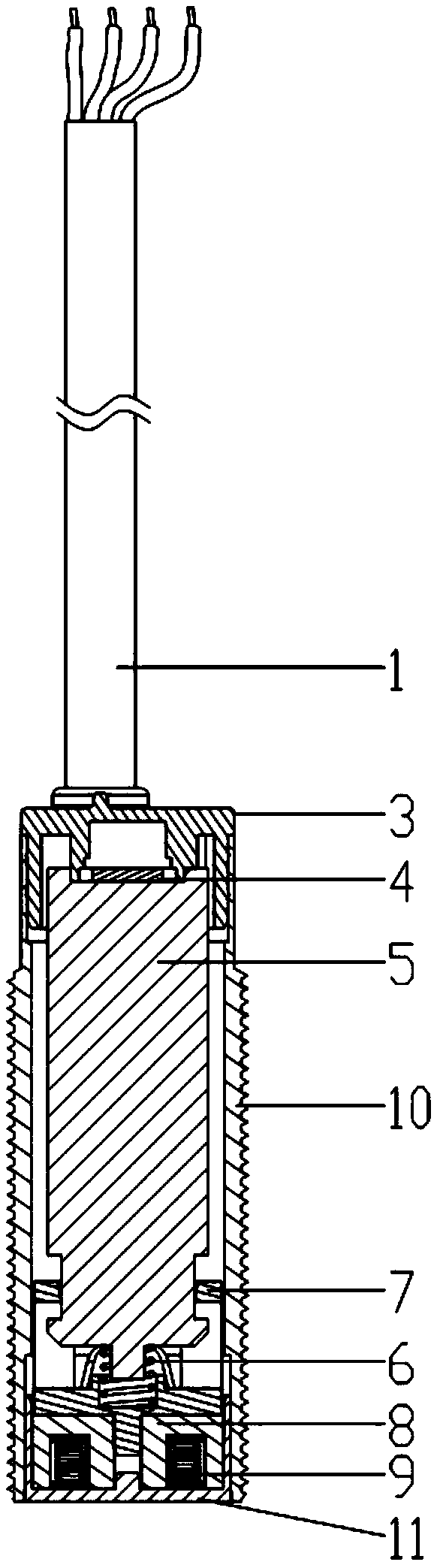

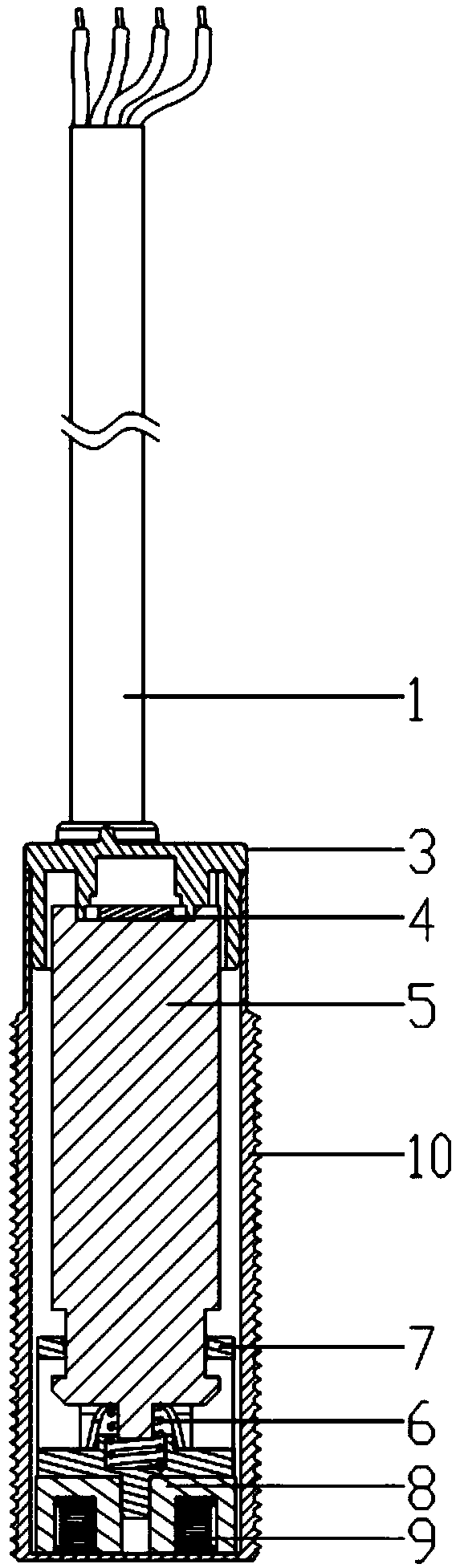

[0015] Such as figure 1 , figure 2 , Figure 4 as shown, figure 1 It is a schematic diagram of the overall assembly of the plastic front plug and the metal casing of the present invention; figure 2 It is a schematic diagram of the cross-sectional structure of the plastic front plug+metal shell of the present invention; Figure 4 It is a schematic diagram of the structure of semi-finished products assembled with internal components of the present invention; this embodiment provides a proximity sensor, including: four-core wire 1, sealing plug 2 and rear plug 3, LED small PCBA 4, main board PCBA 5, spring 6, magnetic core bracket 7. The magnetic core 8, the coil bobbin 9, and the metal shell 10, the coil bobbin 9 is packed into the magnetic core 8 with interference, the magnetic core support 7 is connected with the magnetic core 8 and the coil bobbin 9, and the spring 6 Put it into the positioning hole of the magnetic core bracket 7, the main board PCBA 5 is snapped into t...

Embodiment 2

[0027] Such as image 3 Shown is a schematic cross-sectional structure diagram of the all-metal shell of the present invention; on the basis of embodiment 1, this embodiment adds a front plug 11, and the front plug 11 and the metal shell 10 have an interference fit, and the interference ring is designed in the front plug induction The face-section outer ring can not only play a tight fit to prevent glue leakage, but also not affect the installation of the magnetic core and cause the magnetic core to be crushed; by changing the position of the interference ring of the front plug 11, the risk of crushing the magnetic core 8 is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com