Assembly quality detection system and method based on frequency-response function

A quality inspection method and frequency response function technology, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as visual occlusion and poor light in the working environment, and save manpower, reduce workload, Solve the effect of visual occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

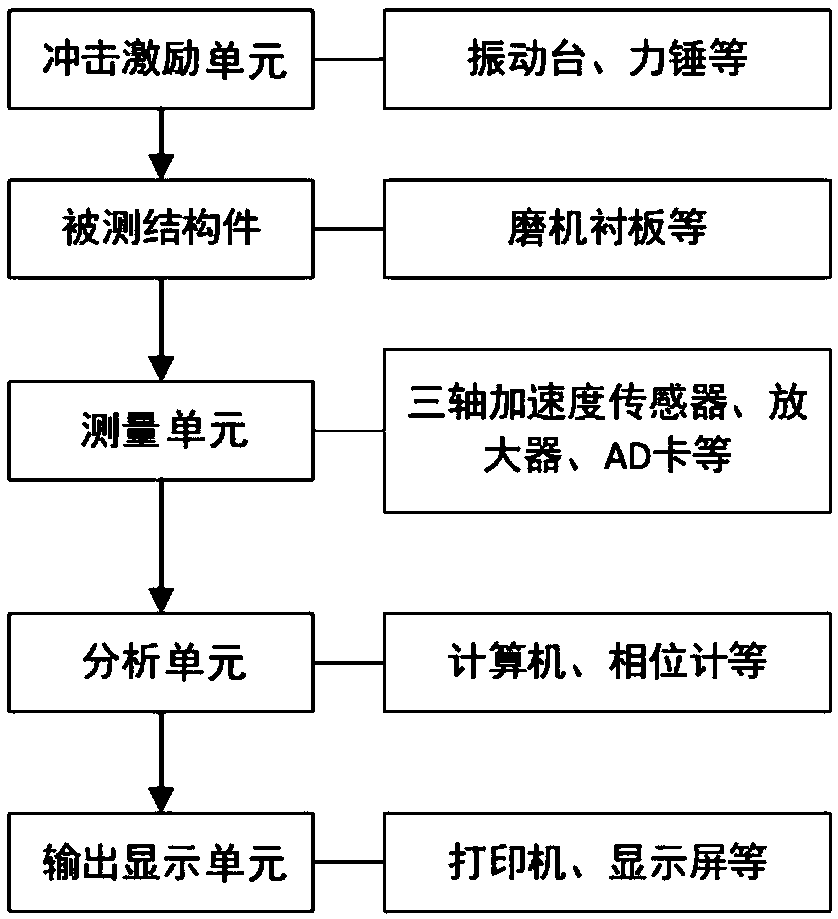

[0059] An assembly quality detection system based on a frequency response function disclosed in one or more embodiments, such as figure 1 As shown, it includes: the impact excitation unit, the structure to be tested, the measurement unit, the analysis unit and the output display unit.

[0060] Among them, the impact excitation unit mainly generates vibration signals through hammers or vibration tables;

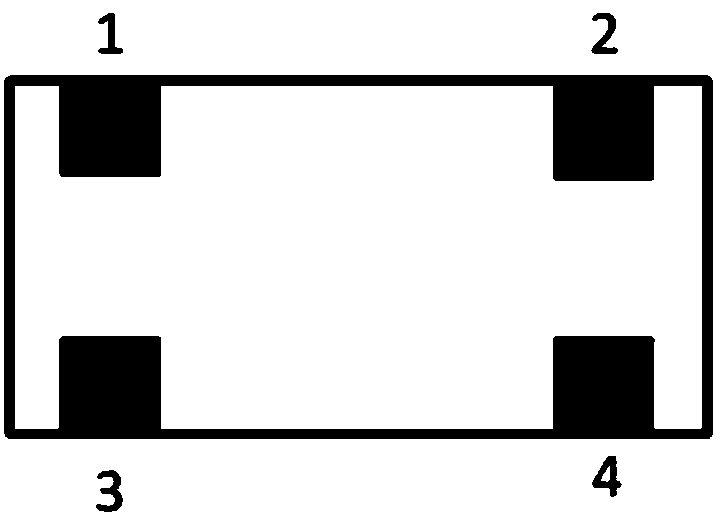

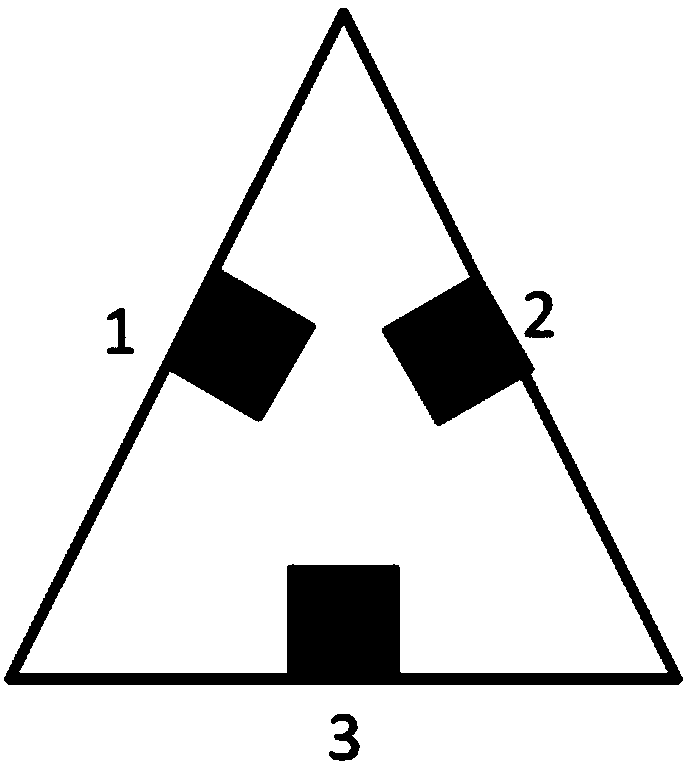

[0061] The structure to be tested is the mill liner, including rectangular and triangular models, as shown in Fig. The selection of points is based on the principle of reflecting the configuration of the structural member to be tested. The shock excitation unit generates shock excitation signals at each measuring point.

[0062] The measurement unit is mainly composed of a sensor and a conditioning circuit; the sensor is a three-axis acceleration sensor, which is set at each measuring point; the conditioning circuit includes a signal amplification circuit and an AD conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com