Temperature compensation system and method for lithium battery capacity measurement, and storage medium

A temperature compensation and lithium battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as high temperature control requirements, and achieve the effect of simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

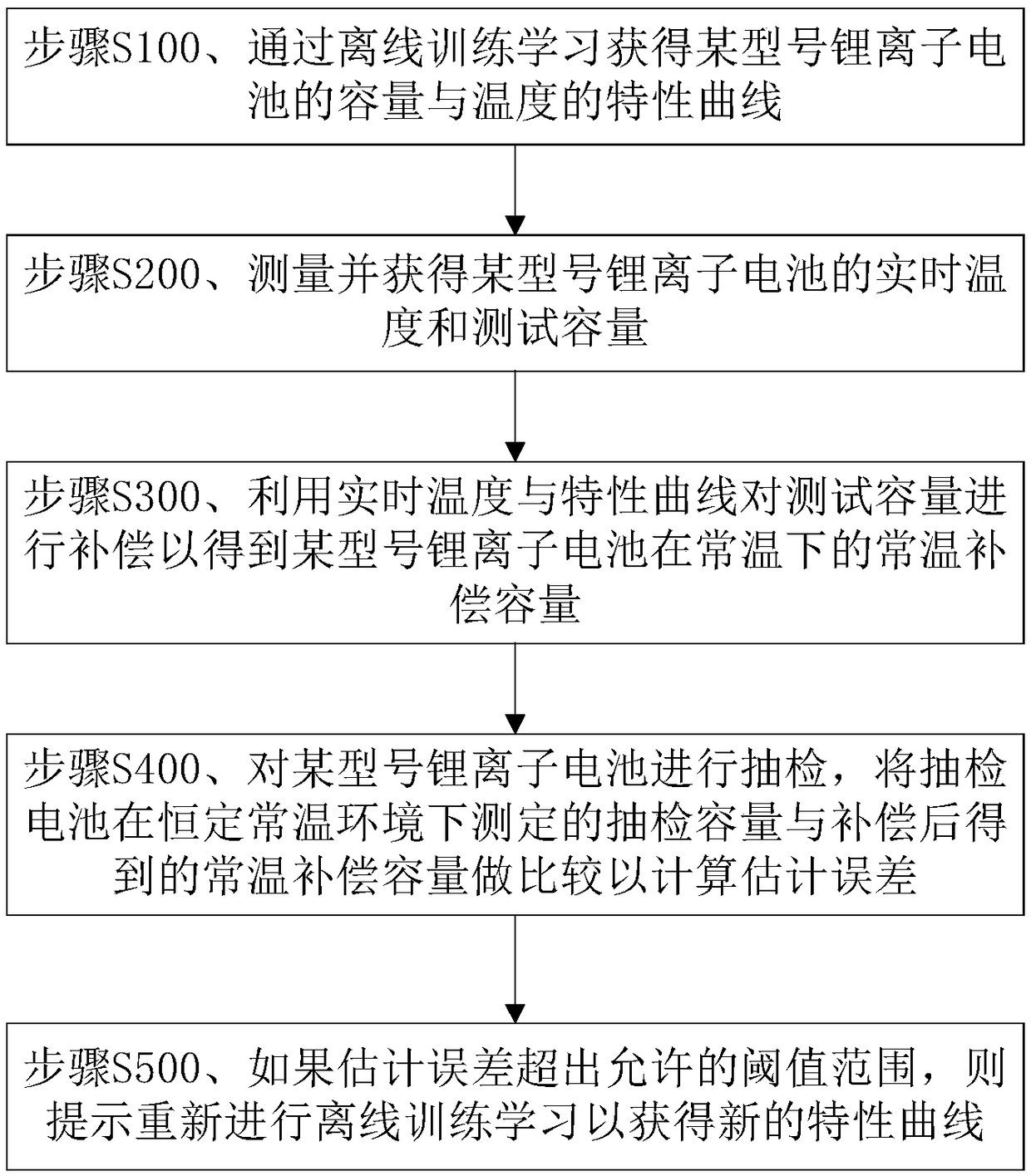

[0022] refer to Figure 1 to Figure 4 , the embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

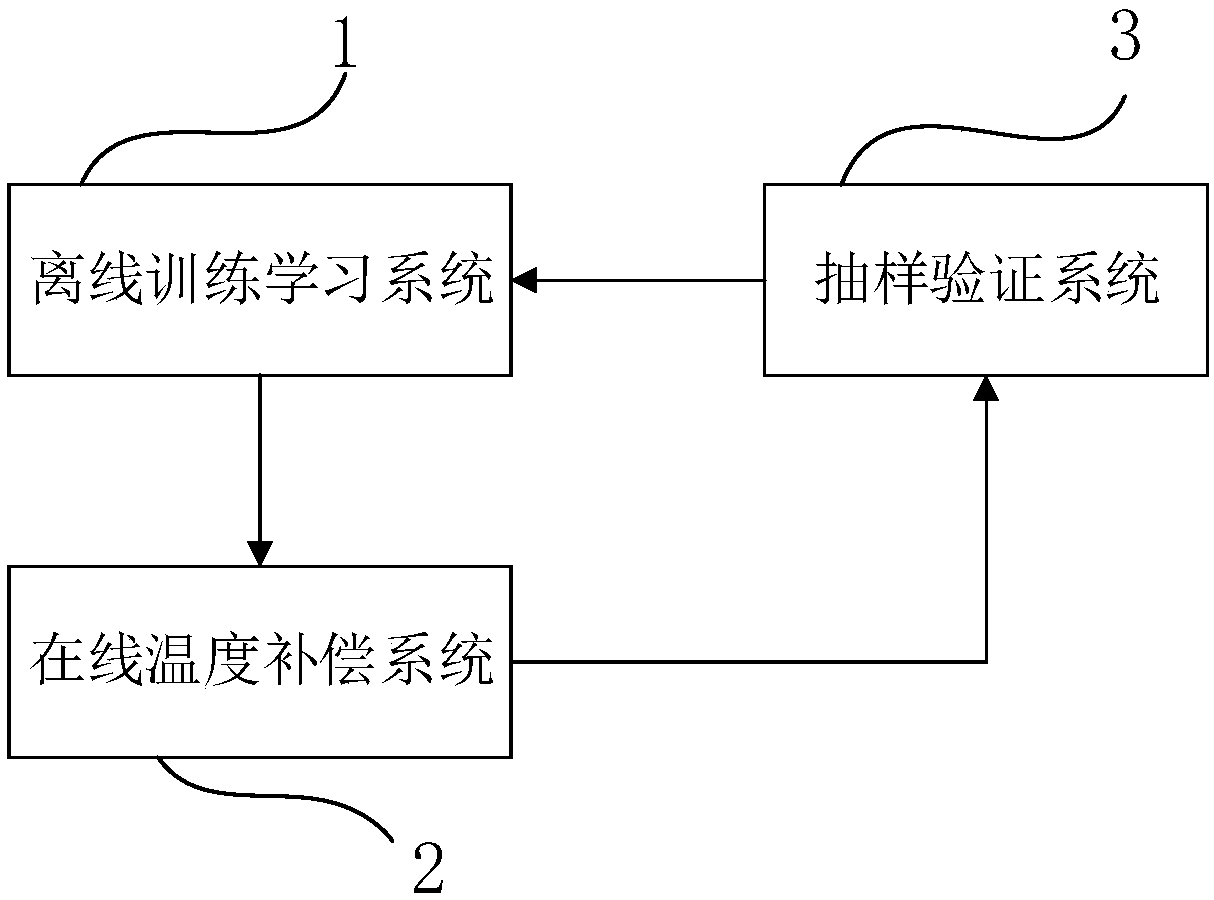

[0023] The temperature compensation system used for lithium battery capacity measurement is a set of intelligent capacity distribution system, refer to figure 1 , which includes an offline training and learning system 1 , an online temperature compensation system 2 and a sampling verification system 3 .

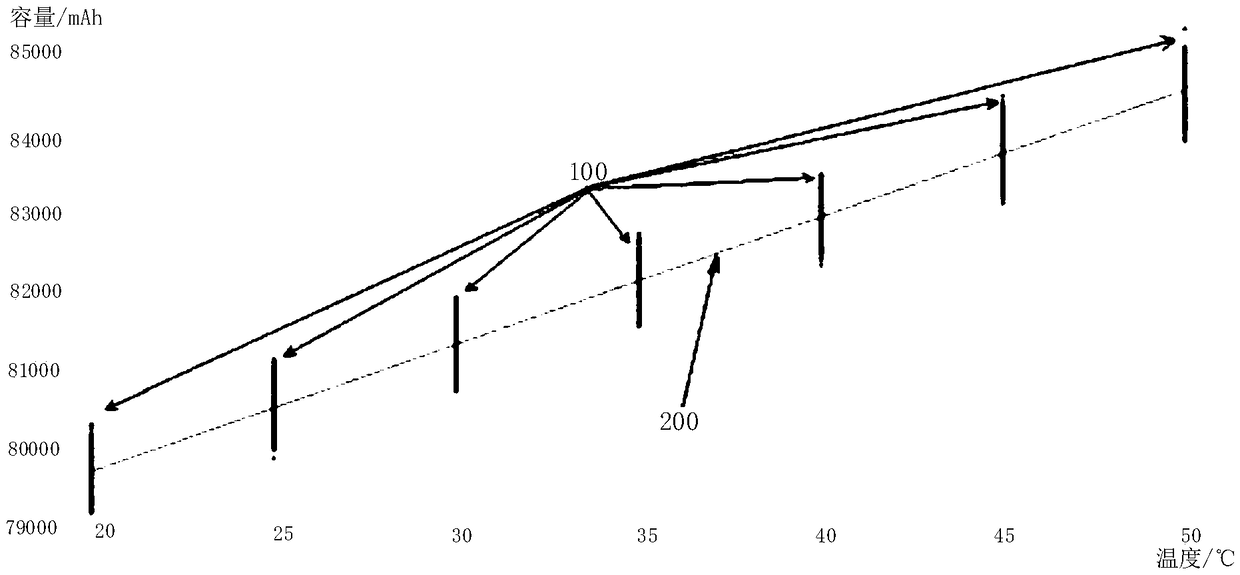

[0024] The off-line training and learning system 1 is used to obtain the characteristic curve of capacity and temperature of a certain type of lithium-ion battery. A certain type of lithium-ion battery refers to a certain type of lithium-ion battery in the production process. The number can be determined according to the actual situation. In order to ensure the accuracy of the data, it is recommended to use more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com