LED free-form surface lens array device for uniform illumination of inclined surfaces

A curved lens, uniform lighting technology, applied in optical components, optics, instruments, etc., can solve the problems of energy waste, deviation of actual light distribution, non-coaxial oblique lighting, etc., to promote application, high energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

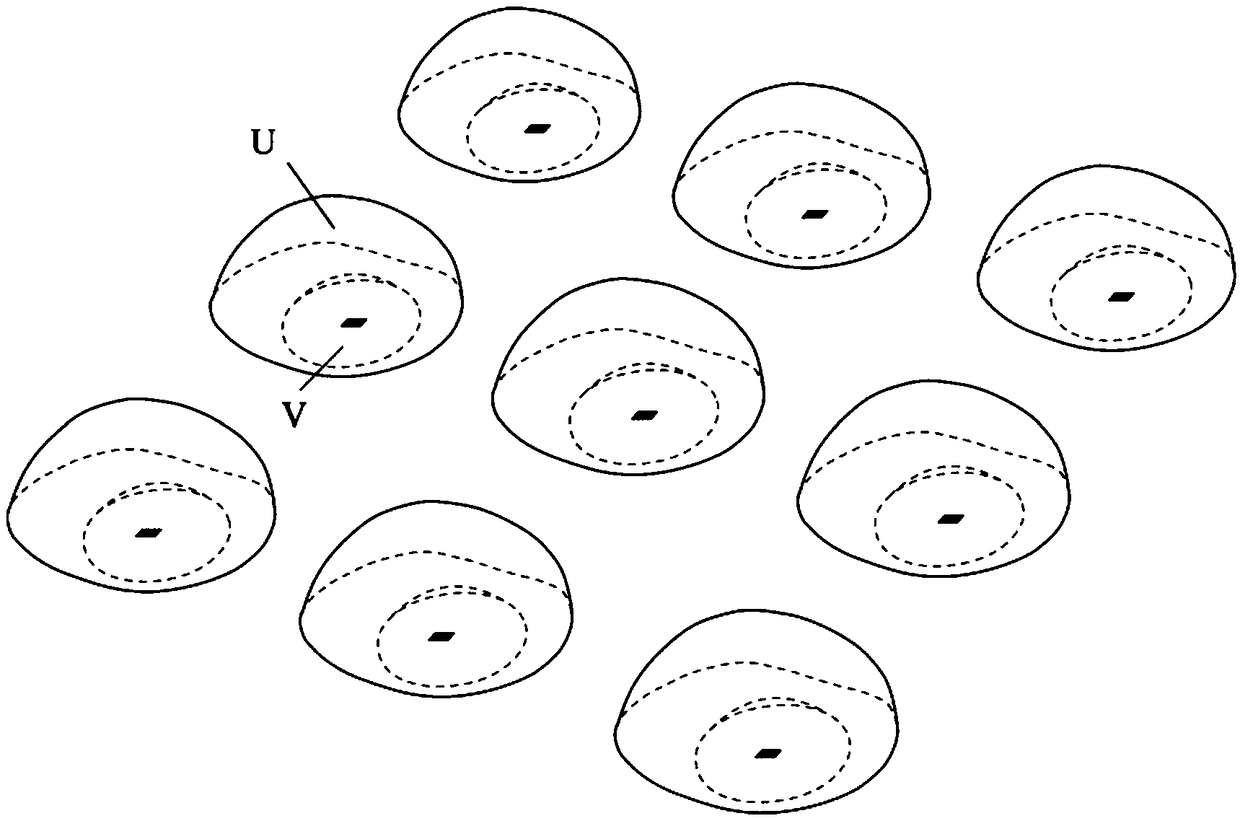

[0041] The LED free-form surface lens array device for uniform illumination on inclined surfaces includes an LED free-form surface lens array composed of free-form surface lens units U uniformly arranged in rows and columns, see attached figure 1 ; Each free-form surface lens unit has the same shape, and each LED light source unit (V) is also the same, and the number of free-form surface lens units (U) and LED light source units (V) is the same, and they are in one-to-one correspondence; The corresponding free-form surface lens unit deflects to produce a predetermined uniform light distribution on the inclined lighting surface; the specific design steps of the free-form surface lens unit are as follows:

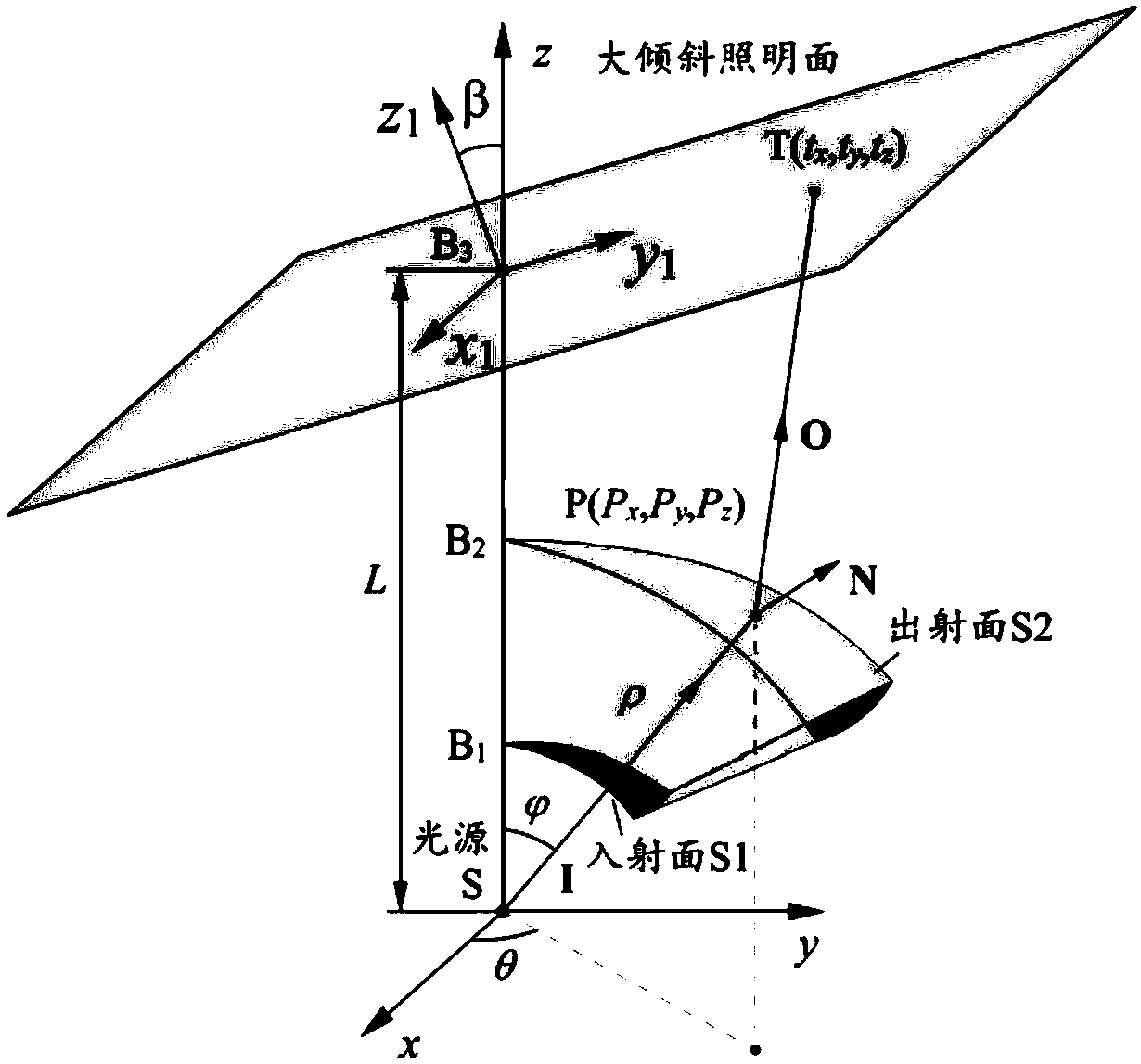

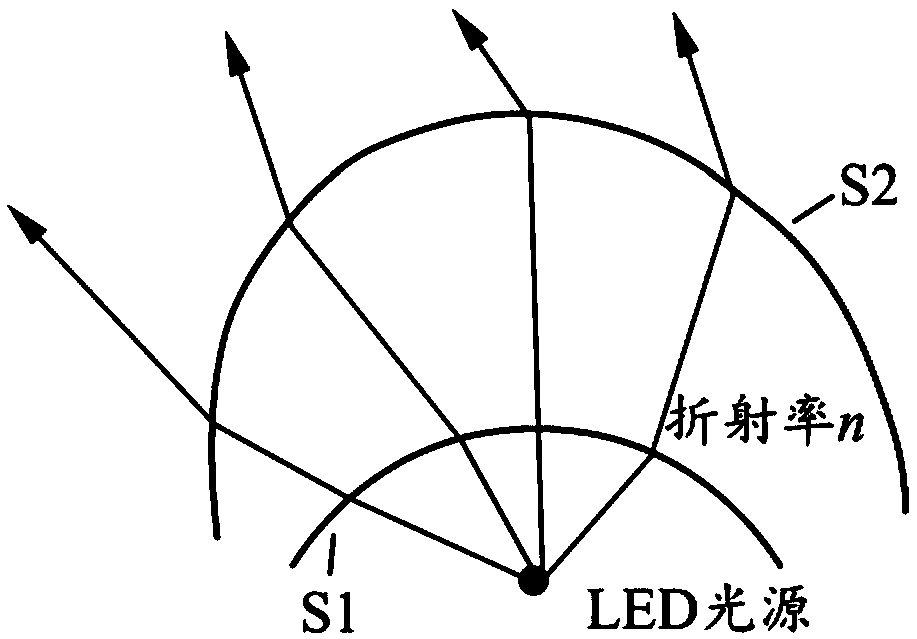

[0042] (1) The optical path structure of the free-form surface lens ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap