Shading mechanism of test lamp box

A technology for testing light boxes and shading cloths, applied in shading, optics, nonlinear optics, etc., can solve problems such as complex structure of shading mechanism, influence on test results, troublesome operation, etc., and achieve the effect of simple structure, improved precision, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

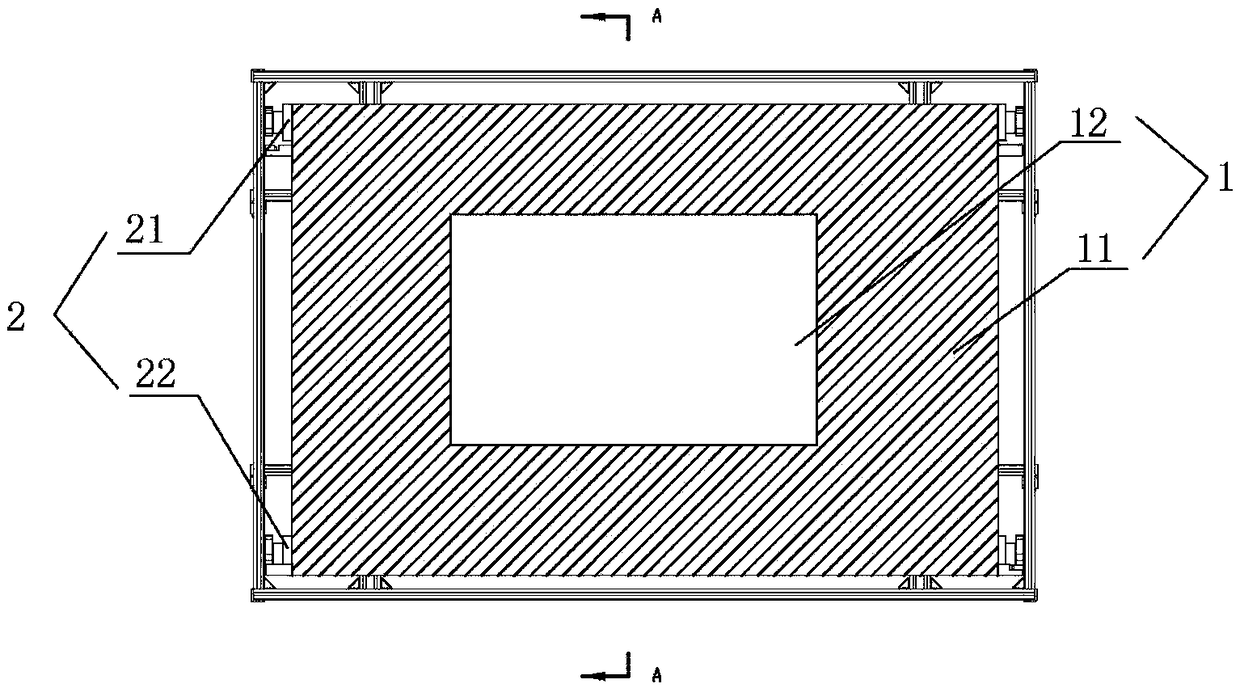

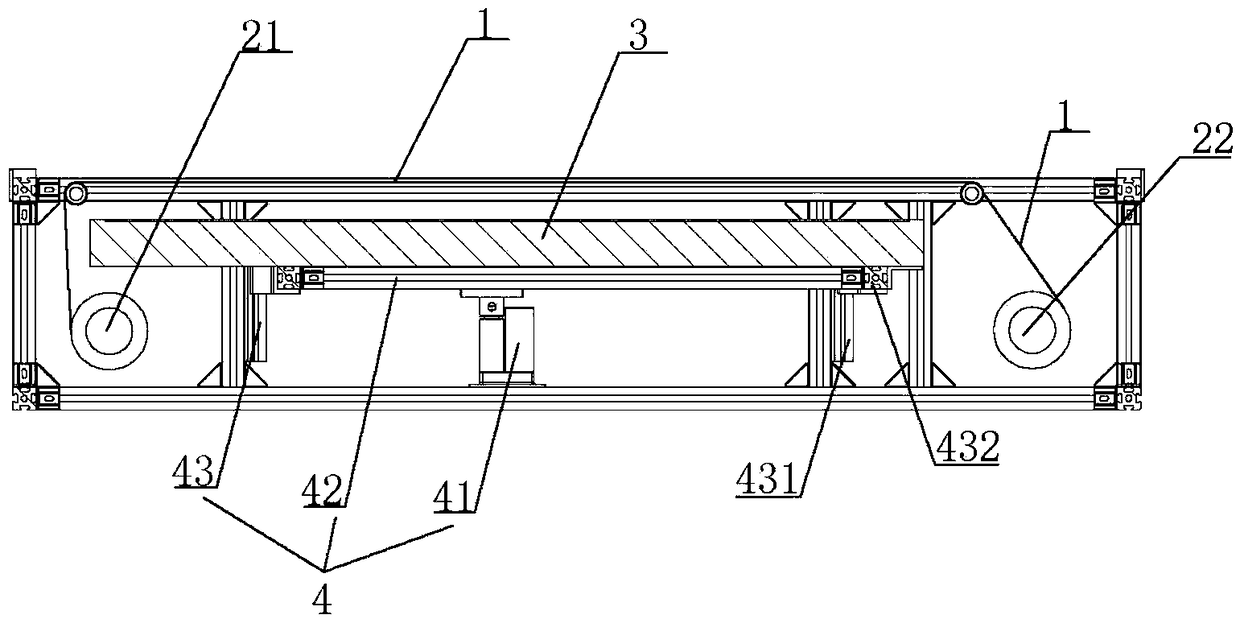

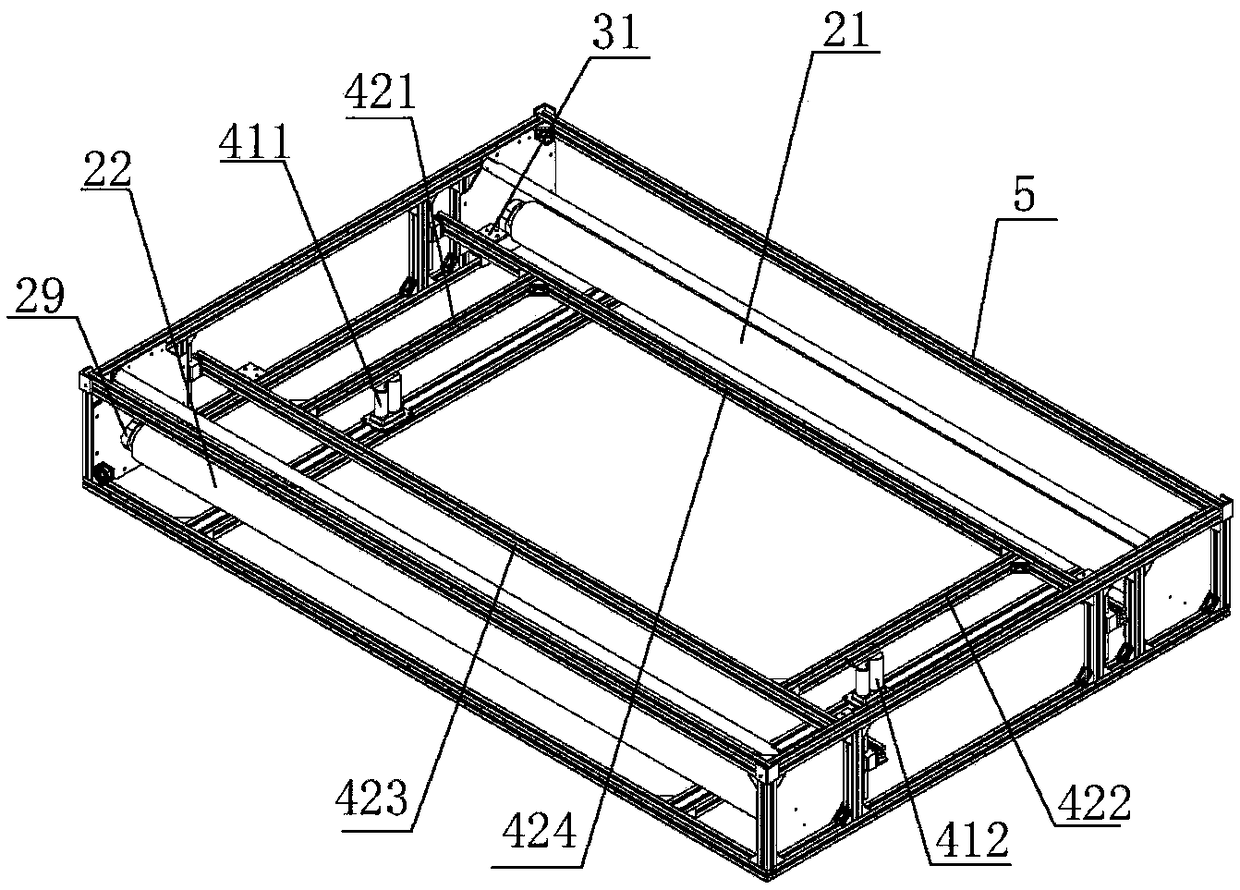

[0026] Test the light box's shading mechanism, such as Figures 1 to 3 As shown, it includes a shade cloth 1, a rolling device 2 and a lifting device 4.

[0027] The shading cloth 1 is provided with a shading area 11 and more than one light-transmitting area 12. The shading cloth 1 is made of a tensile and opaque material. The opaque part is the shading area 11.

[0028] The rolling device 2 includes a first roller 21 and a second roller 22, the first roller 21 and the second roller 22 are respectively arranged on both sides inside the test lamp box, and are fixed on the test lamp box frame 5 by a roller connector 29 Above, the first roller 21 and the second roller 22 are arranged in parallel.

[0029] Both ends of the shade cloth 1 are respectively fixed on the first roller 21 and the second roller 22 , and the shade cloth is wound on the first roller 21 and the second roller 22 .

[0030] Lifting device 4 is arranged on the below of shading cloth 1, comprises driving elem...

Embodiment 2

[0037] A shading mechanism for testing light boxes such as Figure 4 As shown, the shading mechanism includes a shading cloth 1 and a rolling device. At the same time, a light source unit 3 is arranged in the test light box. The light-transmitting area 12 is hollowed out on the light-shielding cloth 1 during production, and the surrounding opaque parts are the light-shielding areas 11, and each light-transmitting area 12 corresponds to a product size of a type.

[0038] The rolling device 2 includes a first roller 21 and a second roller 22, the first roller 21 and the second roller 22 are respectively arranged on both sides inside the test lamp box, and are fixed on the test lamp box frame 5 by a roller connector 29 Above, the first roller 21 and the second roller 22 are arranged in parallel, the shading cloth 1 is connected end to end, and the side is ring-shaped, and is wound on the first roller 21 and the second roller 22. At this time, the light source unit 3 is placed in...

Embodiment 3

[0041] A shading mechanism for testing light boxes such as Figures 5 to 6 As shown, the shading mechanism includes a shading cloth 1 and a rolling device 2. At the same time, a light source unit 3 is arranged in the test light box. Made of drawn, opaque material, the light-transmitting area 12 is hollowed out on the light-shielding cloth 1 during production, and the surrounding opaque parts are the light-shielding areas 11, and each light-transmitting area 12 corresponds to a product size of a model .

[0042] The rolling device 2 comprises a first rack 23, a second rack 24, a first gear 25, a second gear 26, a third gear 27 and a fourth gear 28, and the first rack 23 and the second rack 24 are respectively arranged on The back of the shading cloth 1 is fixedly connected to the two sides of the shading cloth 1, the first rack 23 and the second rack 24 are arranged in parallel, the first gear 25 and the third gear 27 mesh with the first rack 23, and the second gear 26 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com