A method for designing and realizing a color lampshade with complex structure suitable for 3D printing

A complex structure, 3D printing technology, applied in the field of industrial design and manufacturing, computer-aided design, can solve the problems of small number of color 3D printers, limited application of colored lampshades, high price, etc., achieve color types and colors adjustable, easy to manufacture, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

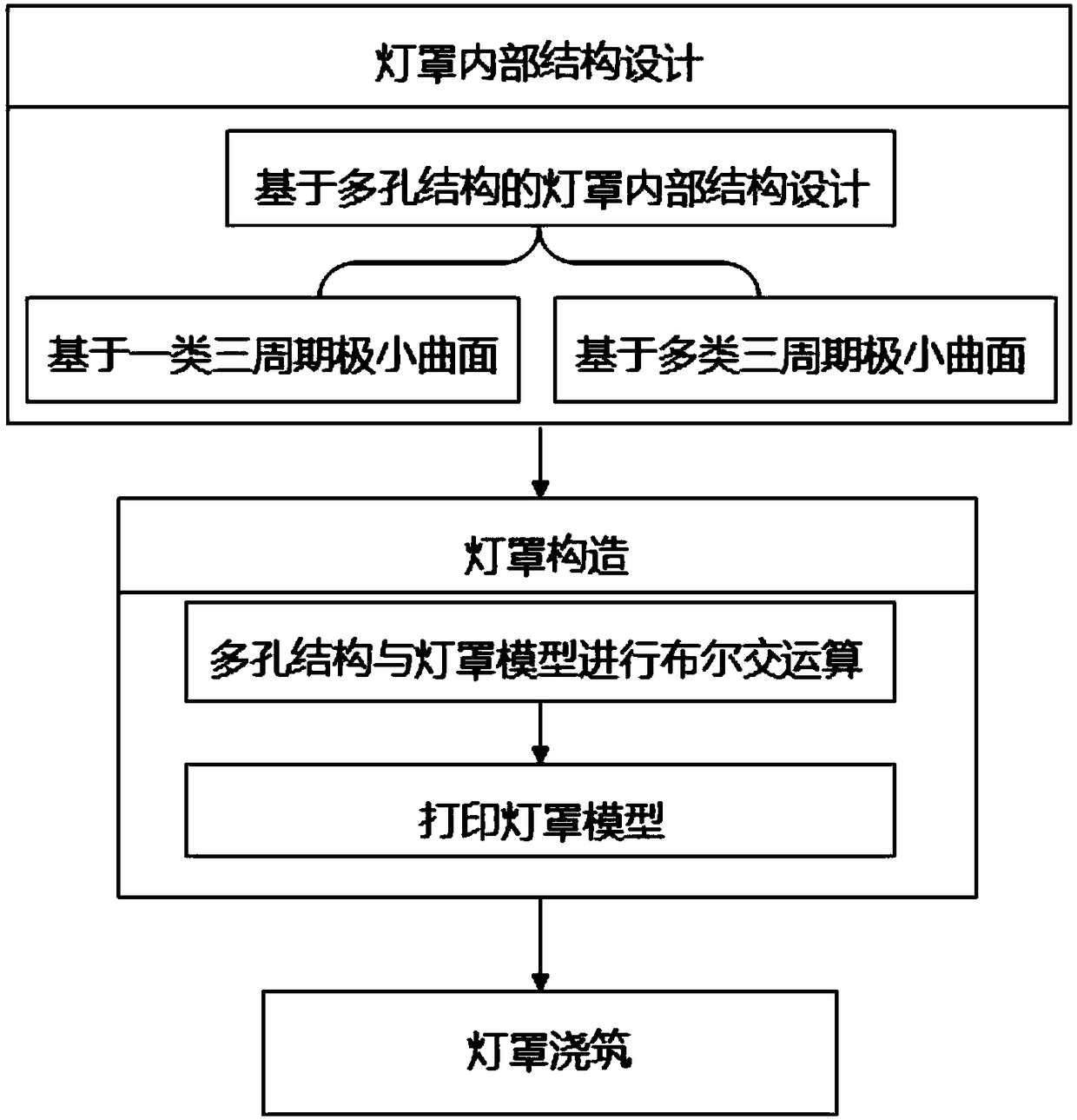

[0043] A method for designing and implementing a complex-structured colored lampshade suitable for 3D printing, which can be divided into several main steps: designing the porous shell structure inside the lampshade, constructing the lampshade, printing the base structure of the lampshade, and pouring the colored solution:

[0044] (1) Porous shell structure design inside the lampshade

[0045] Taking the G surface as an example, there are many

[0046] Porous shell structure, first construct multi-scale three-period minimal surface:

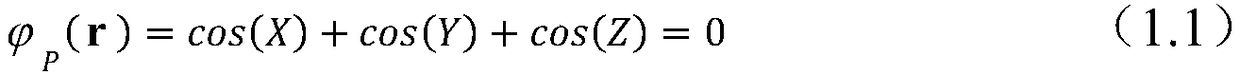

[0047]

[0048] Among them, r is a three-dimensional vector, X=2tπx, Y=2tπy, Z=2tπz, x, y, z are the corresponding coordinates, and t is the period control parameter (the value interval is [0.5,2]).

[0049] Next, the porous shell structure of two color spaces is constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com