Electromagnetic system of clapper type magnetic latching relay, and assembly method thereof

A technology of magnetic latching relays and electromagnetic systems, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problem that the operation effect of electromagnetic system relays is not reliable, the connection mode of the impact-resistant structure is not prominent, and the electromagnetic system is not suitable for various Specific issues such as low power consumption, strong anti-vibration ability, and high reliability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

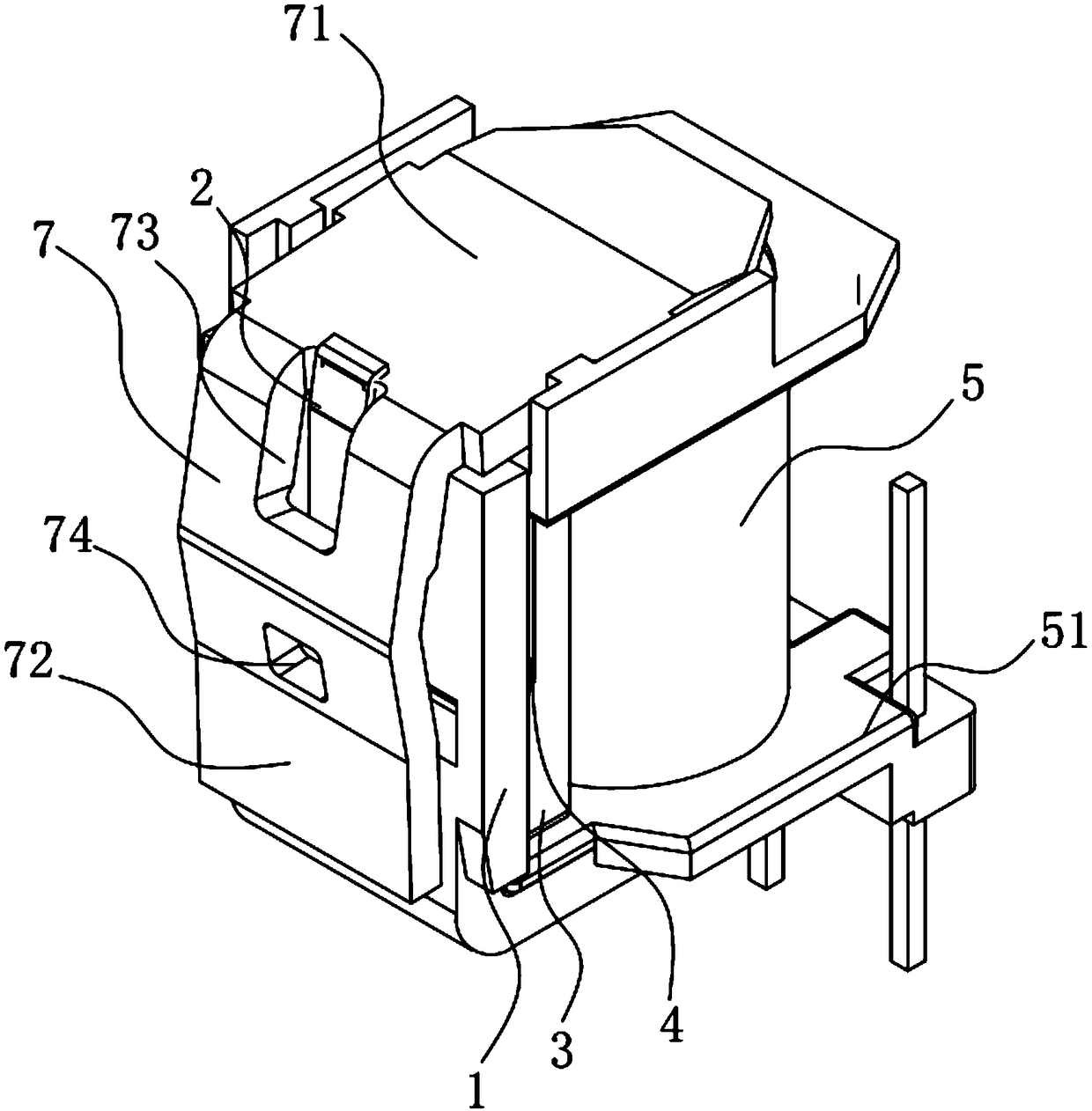

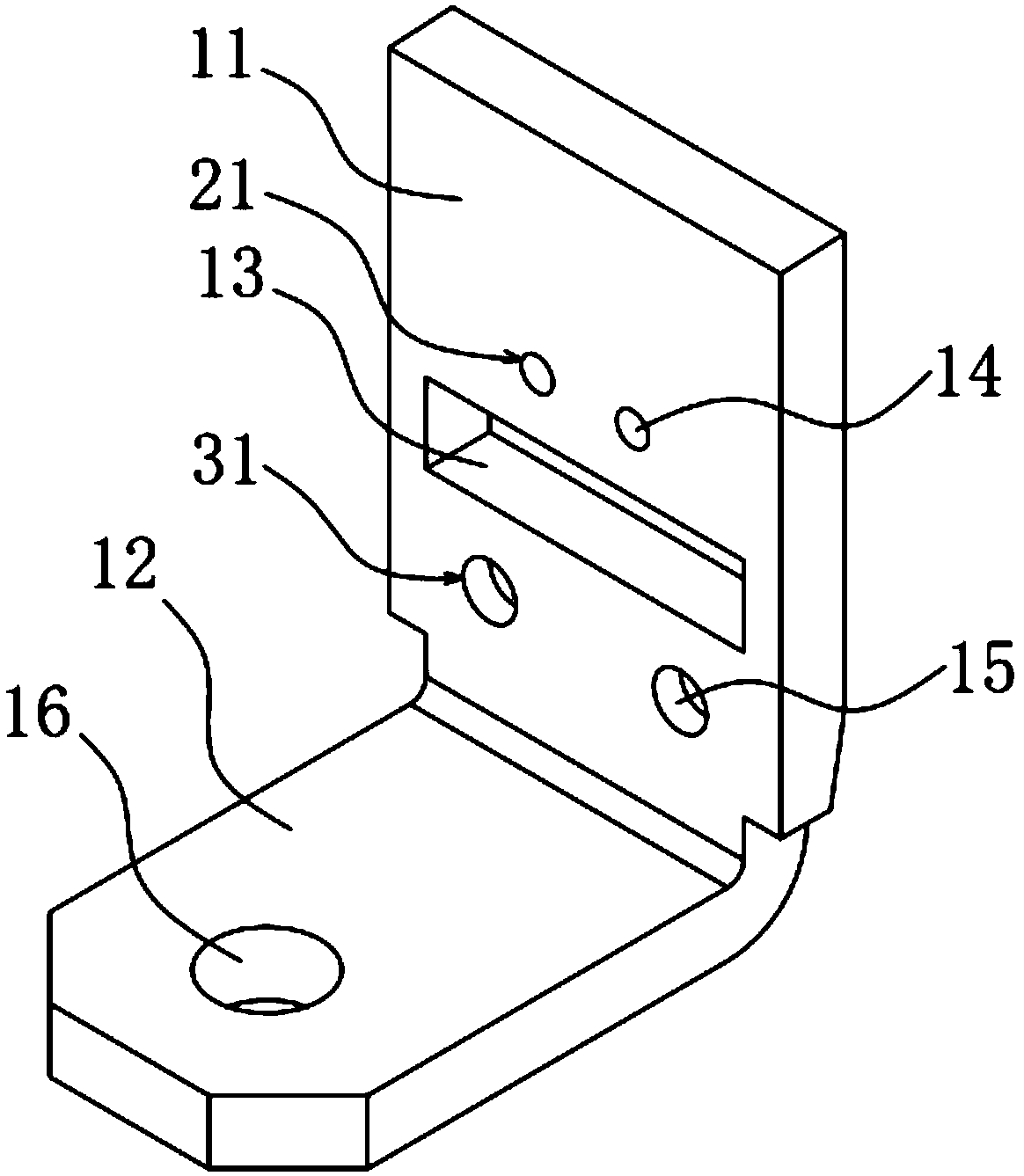

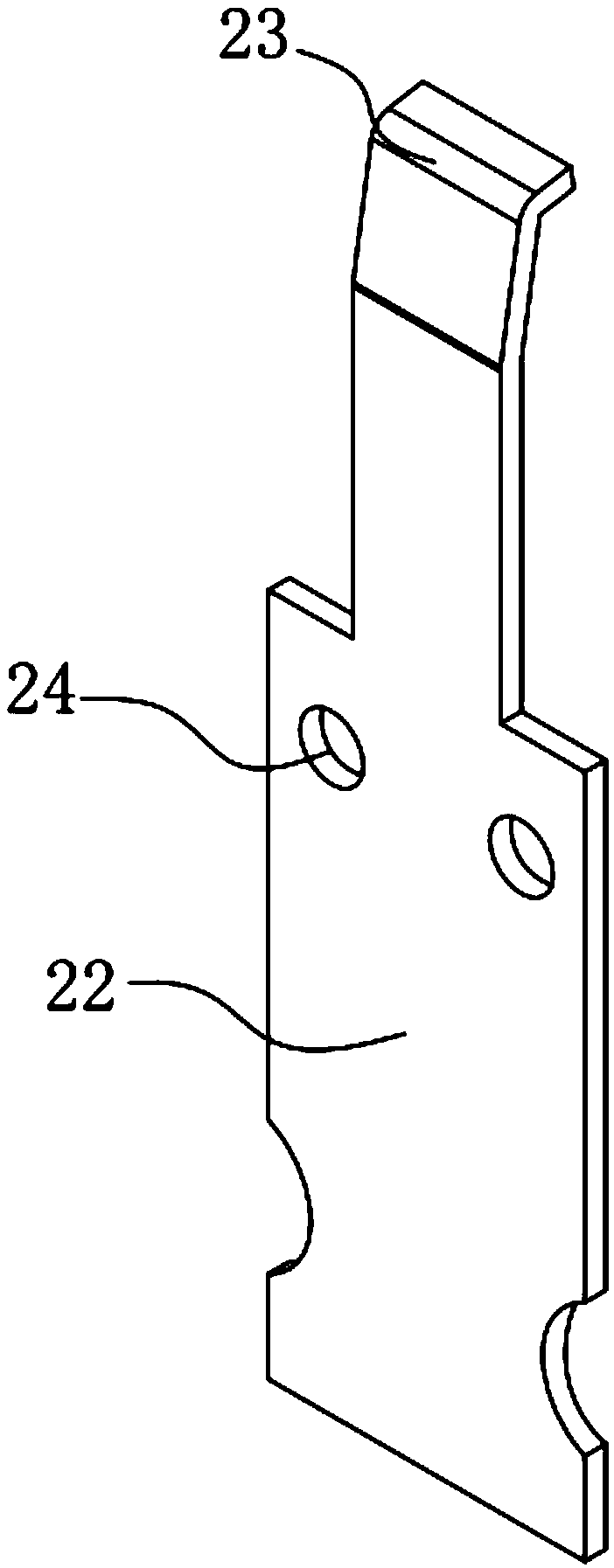

[0033] Such as Figure 1-7 As shown, the clapping-type magnetic latching relay electromagnetic system includes an electromagnetic part and a yoke assembly. The yoke assembly includes an L-shaped yoke 1 having a vertical portion 11 and a horizontal portion 12. The vertical portion 11 of the yoke 1 The outer side is provided with a compression spring 2, the inner side is provided with a magnetic conduction block 3, and the vertical part 11 of the yoke 1 is provided with a rectangular hole 13 which can connect the compression spring 2 and the magnetic conduction block 3, and the compression spring 2 and the magnetic conduction block The blocks 3 are all connected to the yoke 1 through the first riveting structure, and a magnetic steel 4 is provided between the vertical part 11 of the yoke 1 and the magnetic block 3, and the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com