Wiring terminal storage clip and wiring clamp with storage clip

A technology of wiring terminals and wire clamps, applied in the field of wire clamps, can solve the problems of forgetting to carry, inconvenient, and small in size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

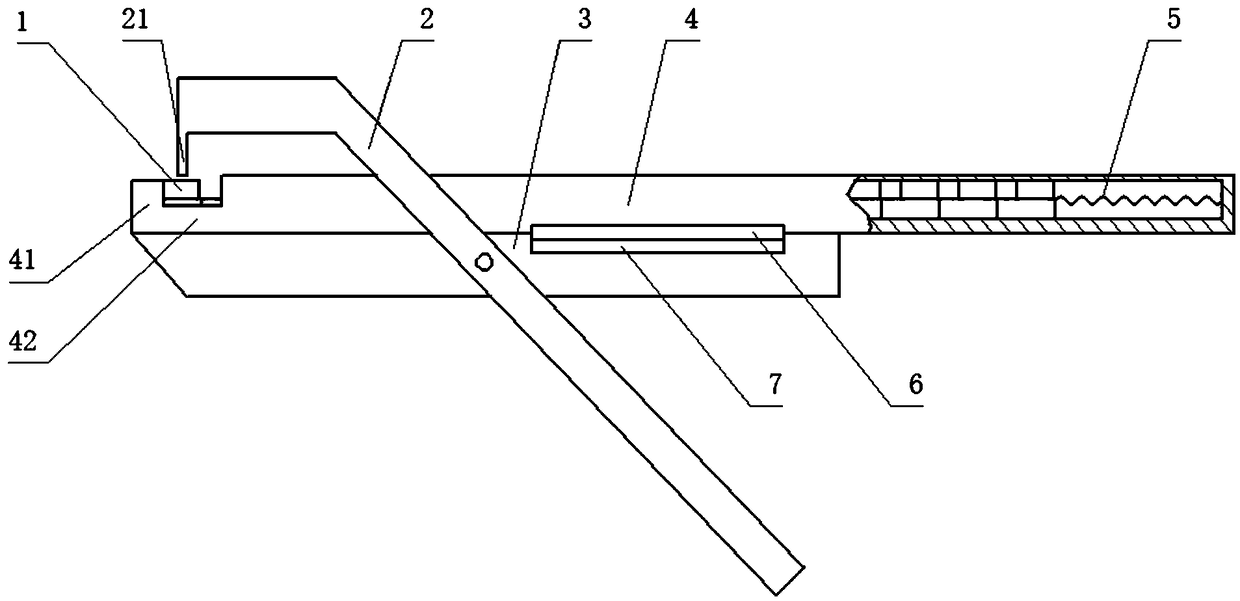

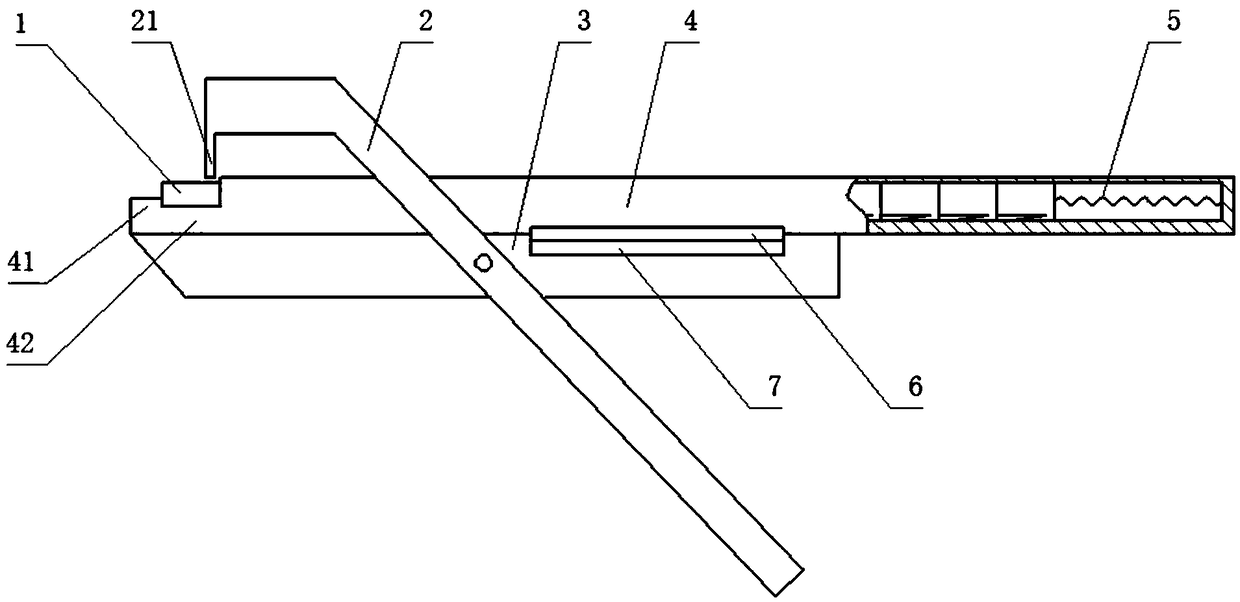

[0037] Such as figure 1 As shown, a wiring pliers used for the terminal 1, the terminal 1 is a 3M brand terminal, such as the K2 model. The storage clip 4 is connected to the body of the second pliers handle 3 . In fact, the two can be fixedly connected.

[0038] refer to figure 2 , The storage clip 4 includes a top wall, a bottom wall and side walls connecting the top wall and the bottom wall, and a long storage space is enclosed inside. figure 1 The left section is the jaw section 42, and the jaw section 42 removes the top wall as the jaw. The length of the jaws is sufficient for the terminal 1 to be pressed into the storage space from the outside.

[0039] The right section is a storage section, in which a spring 5 is arranged, and the terminal 1 that is pressed into the storage section successively squeezes the spring 5 continuously, and is pushed into the jaw section 42 by the thrust of the spring 5 at the same time. A stopper 41 is provided at the left end of the ja...

Embodiment 2

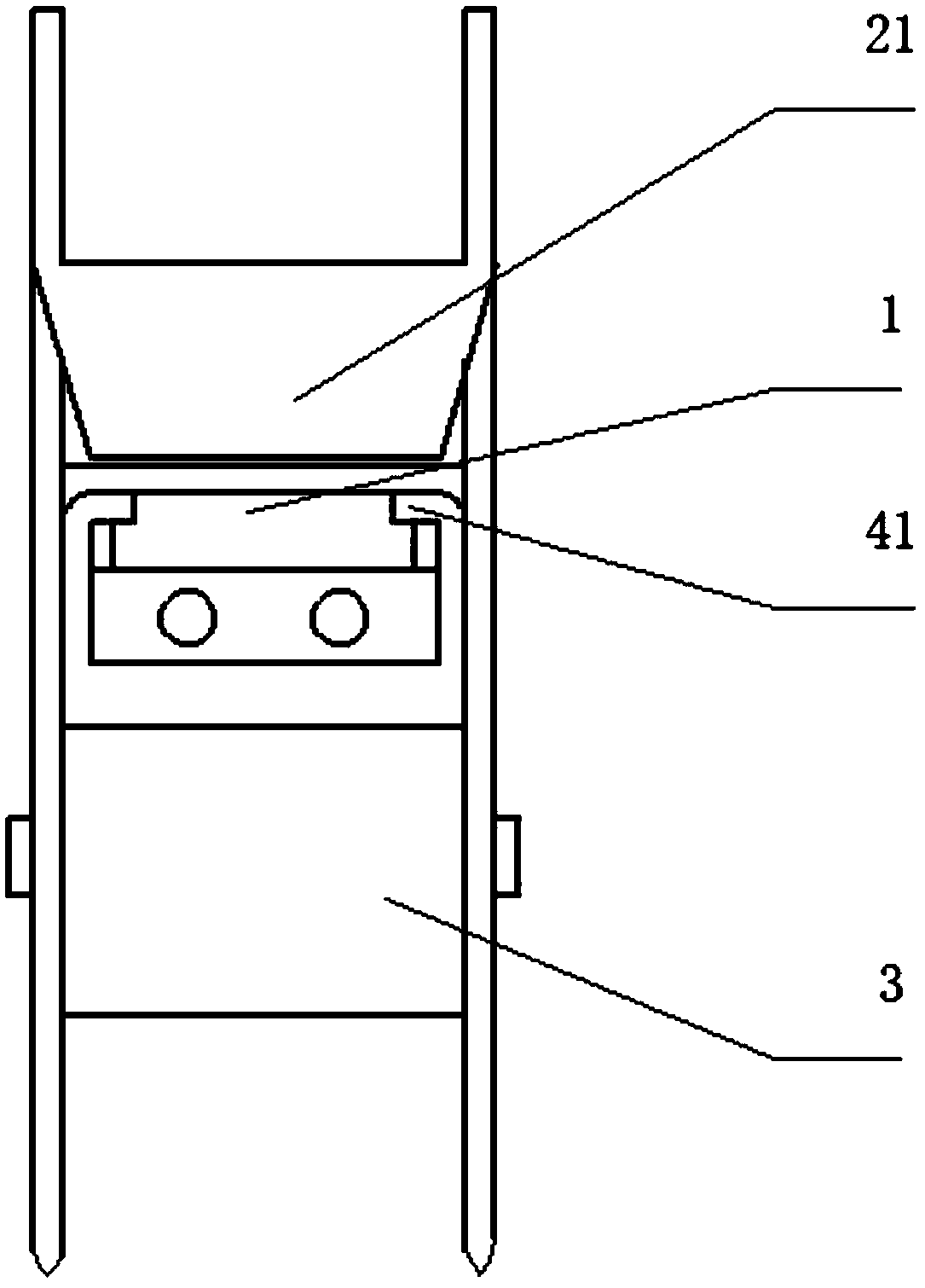

[0046] Such as image 3 , Figure 4 As shown, the connector 1 is a crystal head used for a telephone line or a network cable. The overall dimension does not change when it is pressed.

[0047] The connectors 1 are arranged sequentially in the storage clip 4 , and the interface direction is from the jaw section 42 to the outside. The jaw section 42 has no top wall and the position of the stopper 41 is lower. The line is connected to the terminal 1, and after crimping, the crimped wire end is taken out from the top of the jaw section 42 .

Embodiment 3

[0049] Such as Figure 5 As shown, the storage clip 4 is arranged transversely to the first pliers handle 2 . The side wall of the jaw section 42 is provided with an outlet through which the connecting wire is inserted into the terminal 1 and taken out as a whole.

[0050] can also be in image 3 To improve on the basis of image 3 The middle and transverse pressure plate 21 can be arranged in the same direction as the storage folder 4 . The side wall of the jaw section 42 is provided with an outlet, and the terminals 1 are pre-installed in the storage folder 4 in sequence in a horizontal direction, and the interface faces the outlet of the side wall. The terminal block 1 times block 41 retaining column of the front, after wiring, the whole end of thread is taken out from outlet.

[0051] can also be as figure 1Improved on the basis of the above, the terminal 1 is horizontally arranged in the storage folder 4, and a terminal opening is opened on the side wall, but after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com