Full-automated preparation device for brush with annular handle

A preparation device, a fully automatic technology, applied in the direction of brushes, brush bodies, household appliances, etc., can solve the problems of fully automatic production of ring handles and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

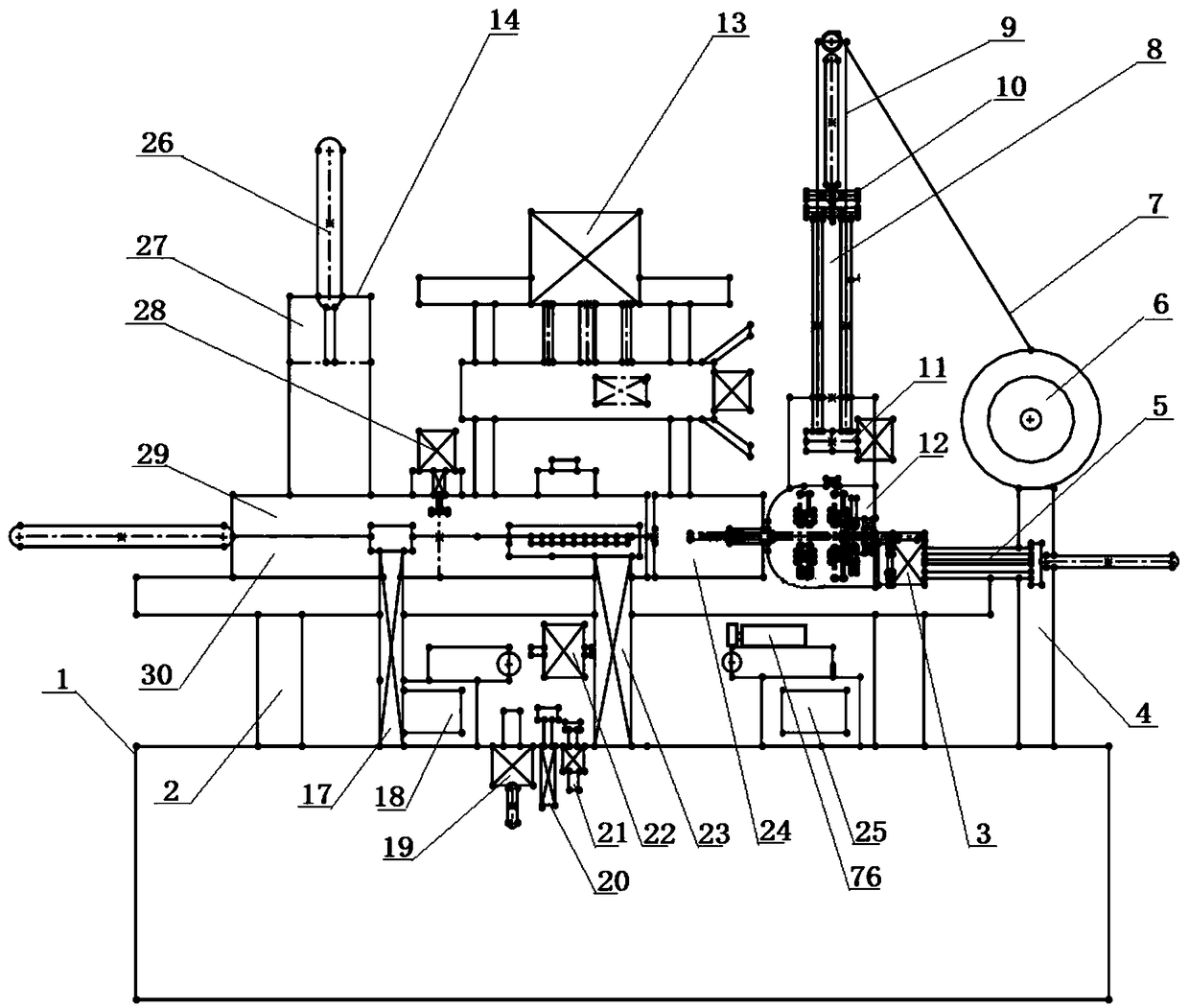

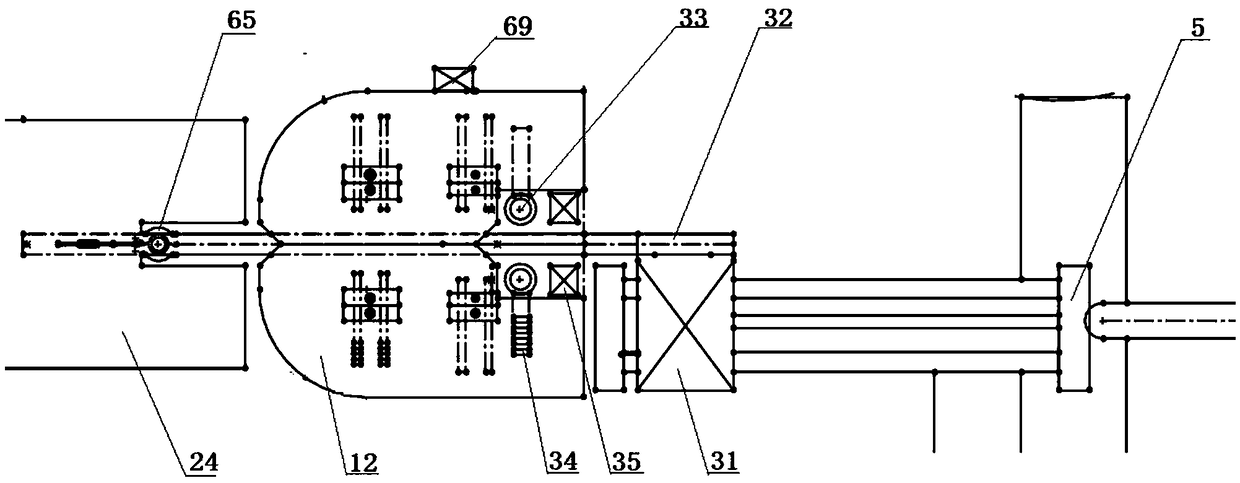

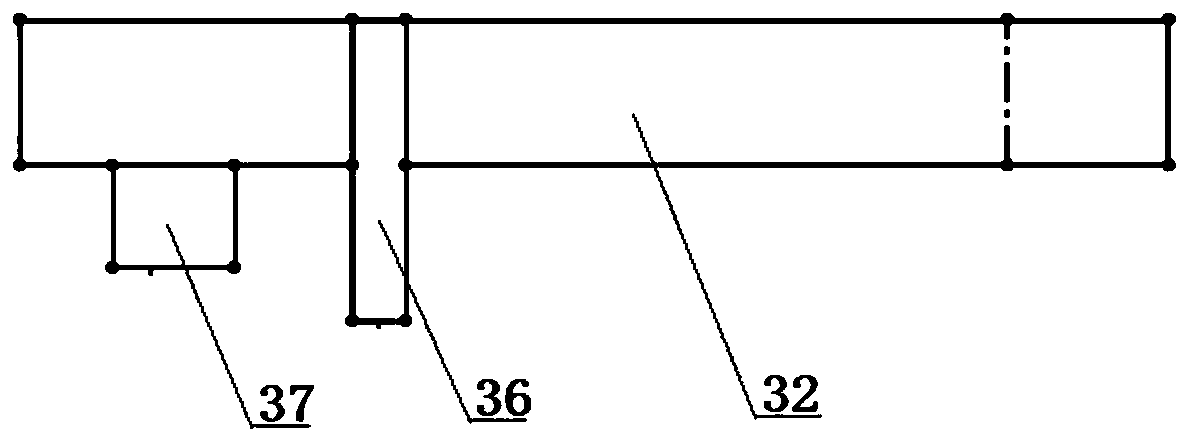

[0046]The full-automatic ring-handle brush preparation device involved in this embodiment has a main structure including a base 1, a base 2, a wire-folding plate 3, a coil support 4, a wire-folding rail 5, a coil 6, an iron wire 7, a wire drawing device 8, Wire drawing rail 9, wire drawing plate 10, wire cutting part 11, wire splint 12, movable guide rail 13, hair feeding device 14, movable rail sensor 15, hair groove 16, first manipulator 17, wire clamping servo motor 18, cutter 19 , sliding table baffle 20, finished product sliding table 21, hair cutting knife 22, second manipulator 23, wire baffle 24, clamp ring servo motor 25, hair pusher 26, hair storage cavity 27, hair plate opener 28, Upper wool board 29, lower wool board 30, pull plate 31, pull rod 32, ring forming roller 33, roller spring 34, ring forming fixing fixture 35, ring forming column 36, wire dividing sheet 37, splint slider 38, splint Slide rail 39, slider spring 40, clamping plate 41, clamping plate openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com