Anti-oscillation drying tank with compact structure

A technology with compact structure and anti-vibration, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of coalescing filter 2 particle clogging, increase and decrease the size of the drying cylinder, and achieve accurate opening pressure and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

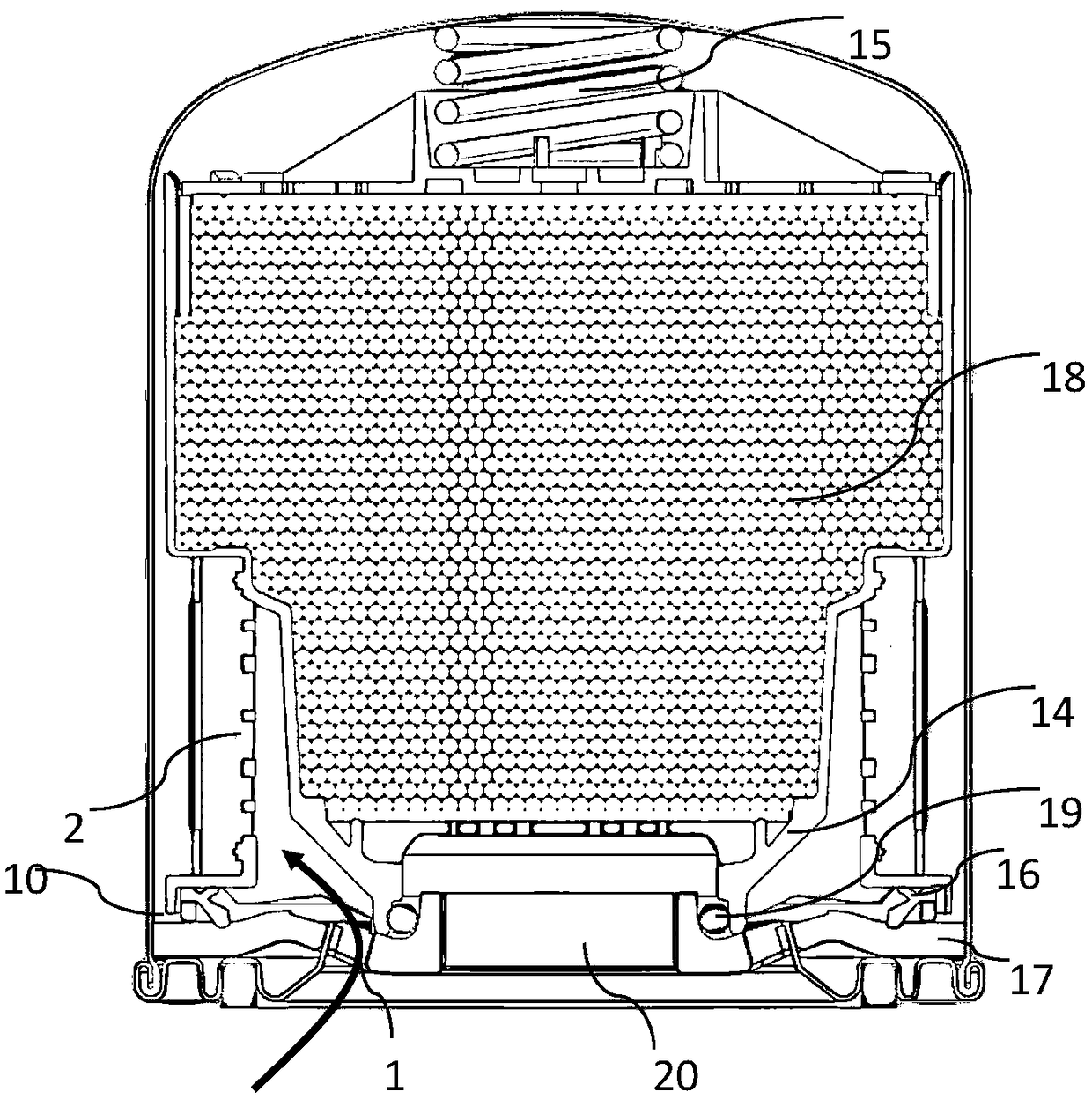

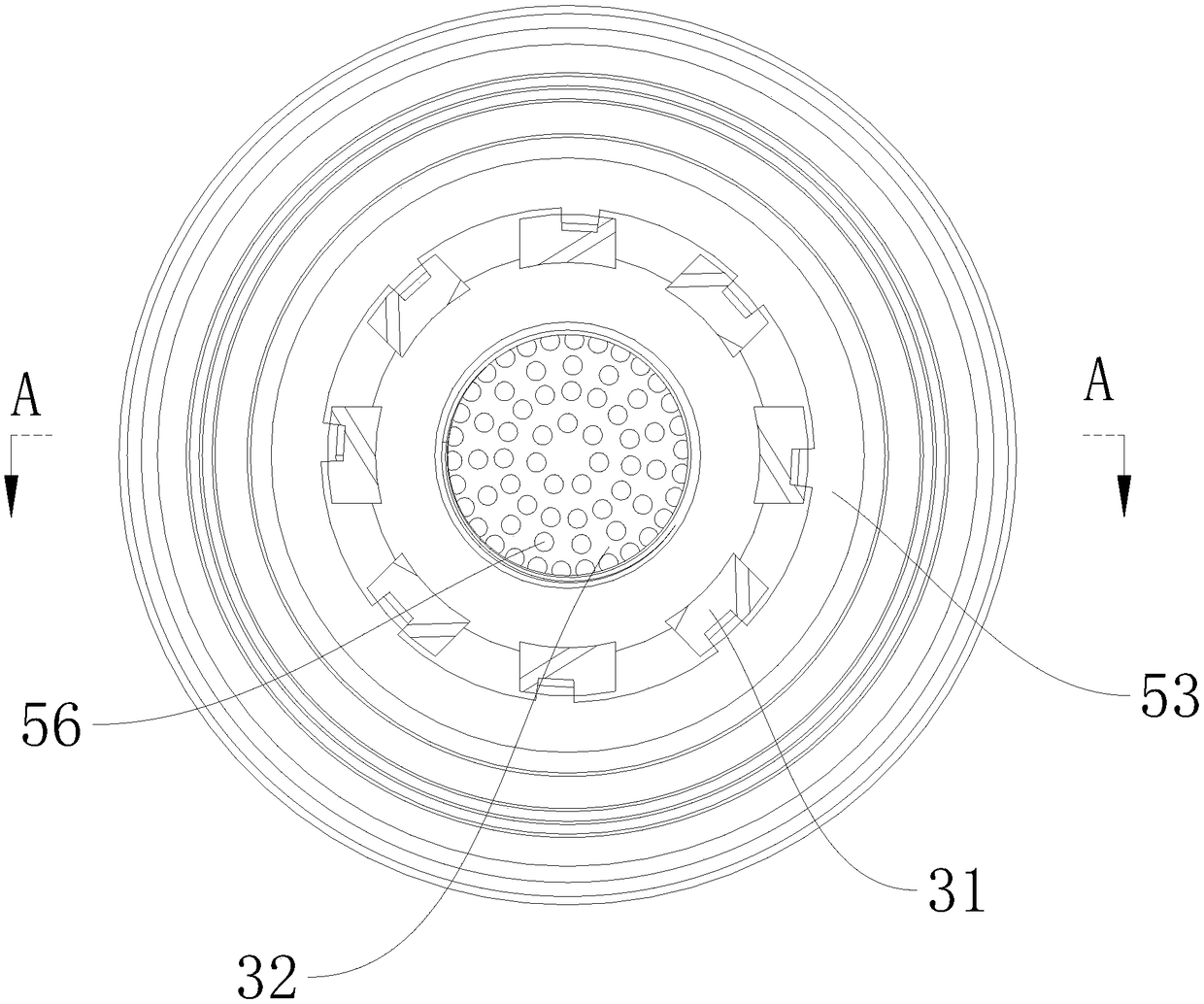

[0039] Such as Figure 2 to Figure 8 As shown, a compact anti-vibration drying tank includes a tank body 30 , wherein the tank body 30 is a cylindrical tank body 30 . The tank body 30 is provided with an air inlet 31 and an air outlet 32. The tank body 30 includes a base plate 53 at the bottom, wherein the air inlet 31 and the air outlet 32 are all opened on the base plate 53, and the air outlet 32 is positioned at the middle part of the base plate 53. The number of air ports 31 is evenly distributed around the air outlet 32 . The tank body 30 is provided with a drying shell 33 , and the drying shell 33 is provided with a drying chamber 34 for containing desiccant, and the drying chamber 34 is placed in the drying chamber 34 . Wherein the drying shell 33 of the drying shell 33 is provided with a coalescing filter 35 for filtering oil particles, and the outer wall of the drying shell 33, the outer wall of the coalescing filter 35 and the inner wall of the tank body 30 en...

Embodiment 2

[0050] A compact anti-vibration drying tank. The difference between this embodiment and Embodiments 1 and 2 is that the coalescing filter element 41 is a cylindrical filter element whose inner diameter gradually increases along the vertical direction, and the first flexible element 46 and the second flexible element 48 are respectively connected to the two ends of the outer rib 46, and the limiting sleeve composed of the outer rib 60, the first flexible element 46 and the second flexible element 48 is detachably sleeved on the coalescing filter core. On the outside, the coalescing filter element 41 is placed in the annular slot surrounded by the first limiting plate 44 , the second limiting plate 45 and the inner rib 60 .

Embodiment 3

[0052] This embodiment provides an automobile vehicle equipped with the compact anti-vibration drying tank of Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com