Diaphragm valve

A diaphragm valve, diaphragm technology, applied in safety valves, balance valves, valve devices, etc., to achieve good air tightness and accurate opening pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

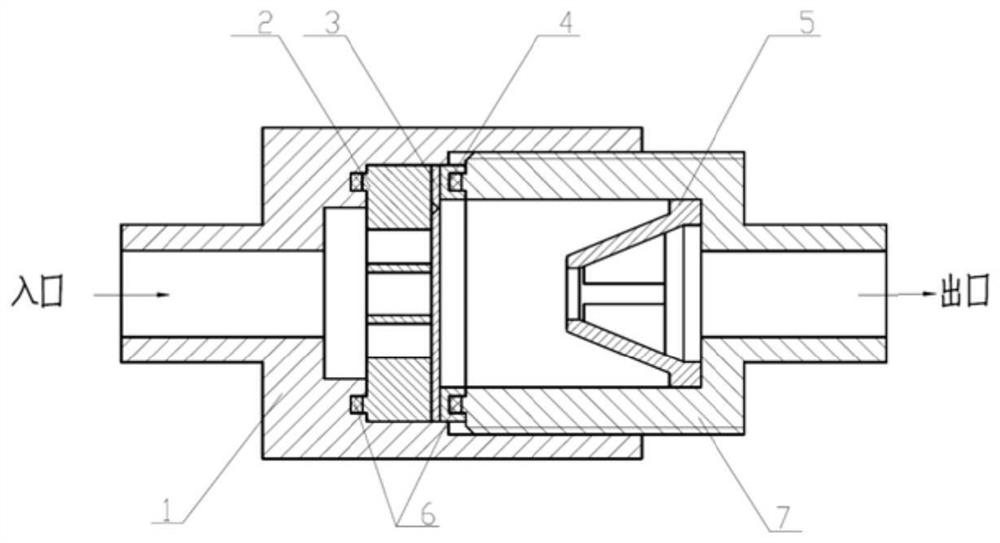

[0042] In a specific embodiment of the present invention, the diaphragm valve is mainly composed of a housing, a grid plate, a diaphragm, a gasket, a nozzle, and a blocking device. The operating temperature of the diaphragm valve is 1000°C. In order to meet the sufficient strength, toughness, stability of material structure and compatibility with the medium under high temperature conditions, the material is made of superalloy GH4202.

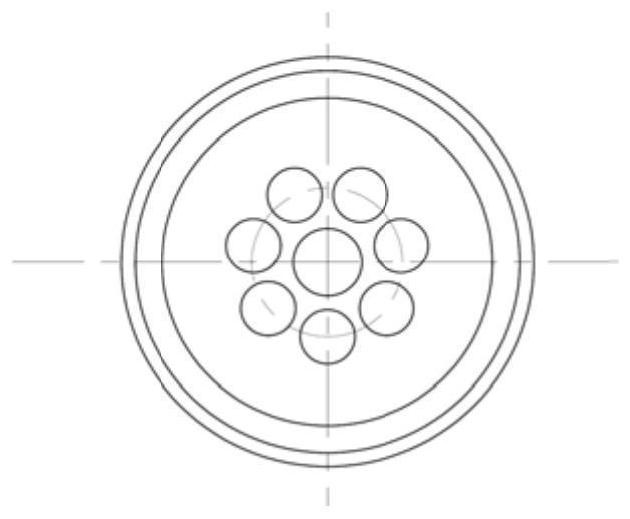

[0043] The grid plate 2, the diaphragm 3 and the washer 4 are welded into a whole, and the grid plate 2 can support the diaphragm not to rupture under reverse high pressure at high temperature. The valve presses the gasket 6 through the shell 1 and the nozzle 5, and the compression gasket 6 uses a graphite mica gasket to ensure the external airtightness of the valve at high temperature and the internal airtightness between the inlet and the outlet. When the valve outlet is under pressure, the circular hole structure grid plate 2 provides reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com