A liquid-sealed safety breathing valve with positive and negative pressure backflow

A breathing valve and negative pressure technology, applied in safety valves, valve devices, balance valves, etc., can solve problems such as inconvenient maintenance and operation of oil storage tank systems, loss of sealing function, safety issues, etc., and achieve active all-weather monitoring and trend recording , Reduce the volume of the valve body, and facilitate cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

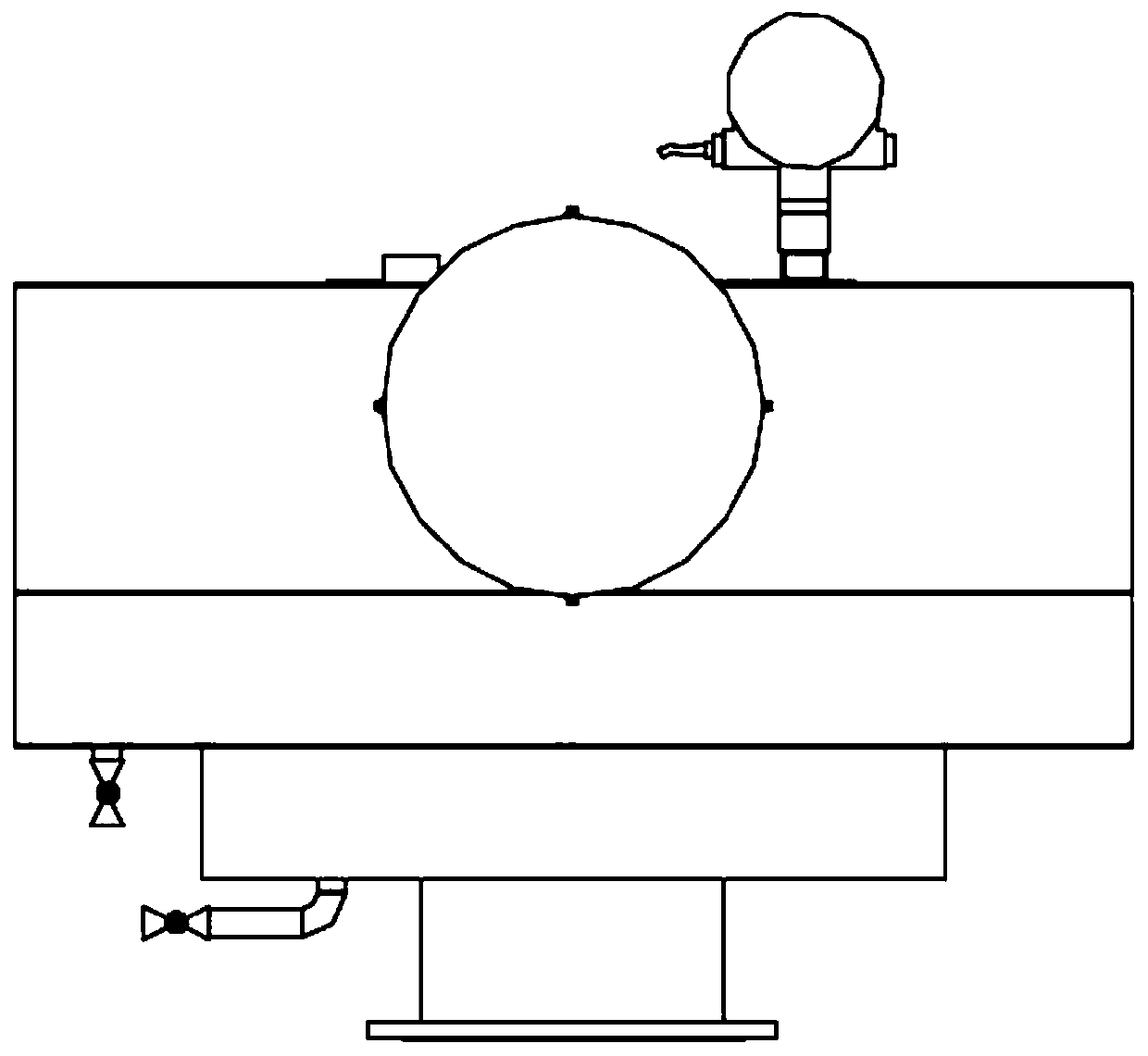

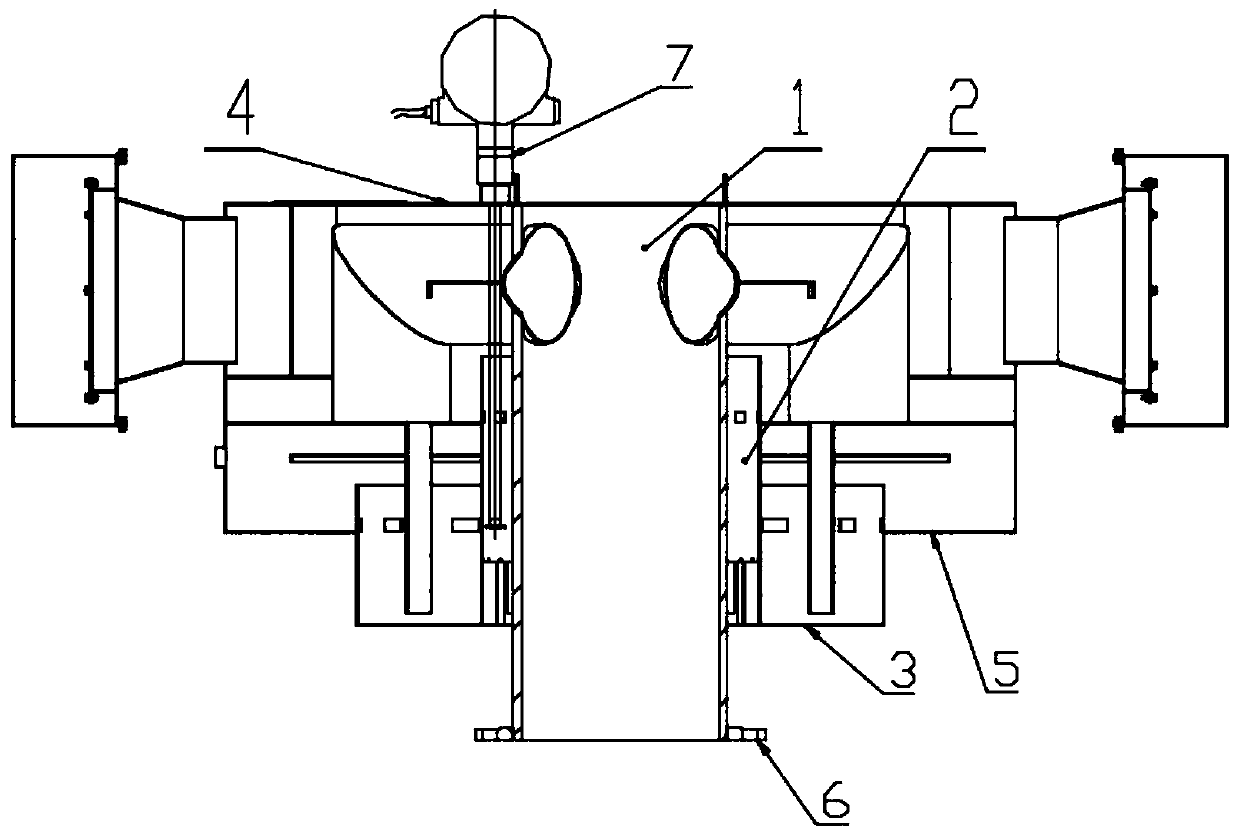

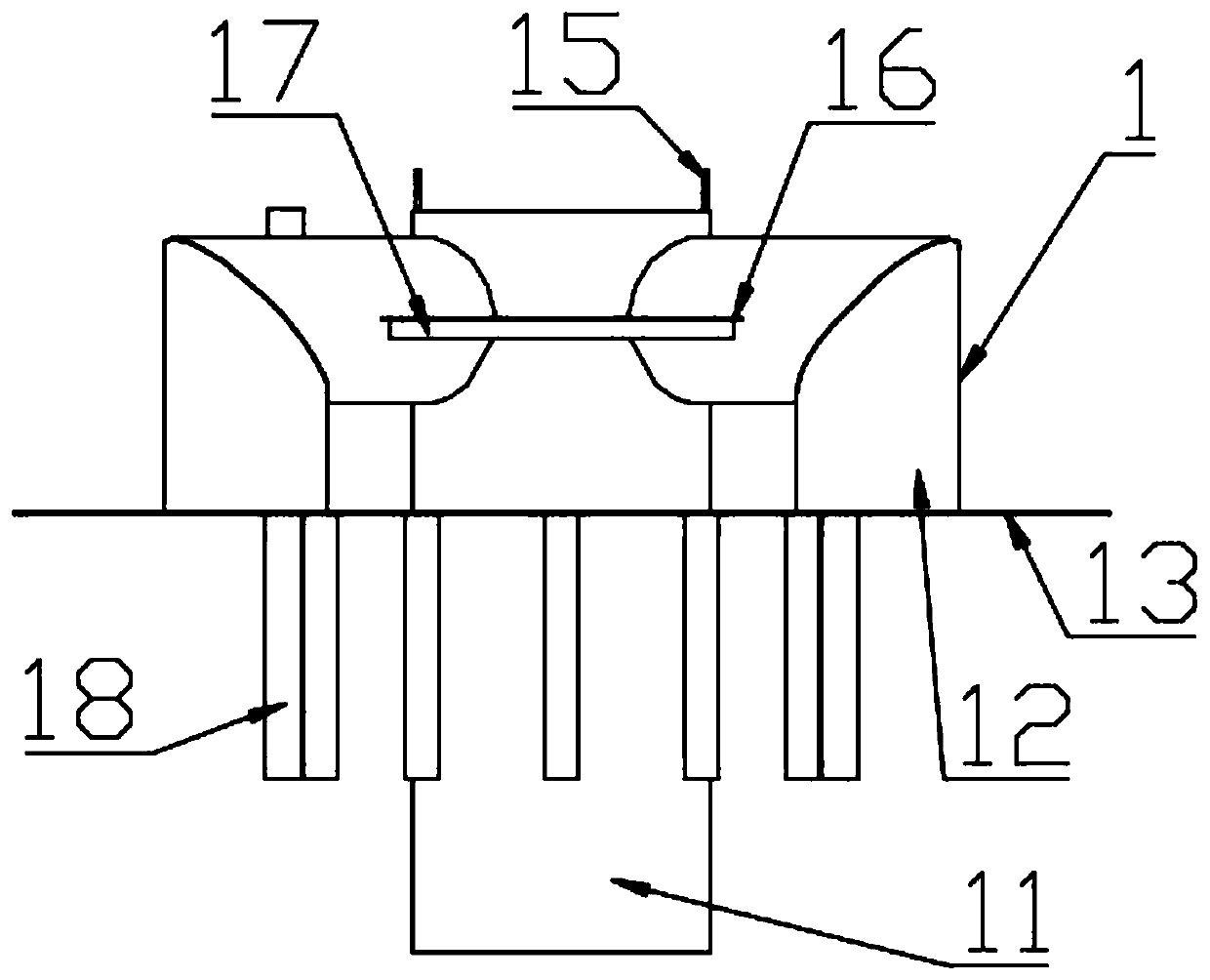

[0054] see Figure 1-22 , in an embodiment of the present invention, a liquid-sealed safety breathing valve for positive and negative pressure reflux, including a vent pipe assembly 1, a liquid barrier barrel assembly 2, a bottom plate assembly 3, an upper end cover plate assembly 4 and a negative pressure product Liquid tank assembly 5; the upper end cover plate assembly 4 and the bottom plate assembly 3 are respectively fixed on the upper and lower ends of the negative pressure liquid accumulation tank assembly 5 to form a cavity, and the ventilation pipe assembly 1 runs through the bottom plate assembly 3 And the liquid barrier barrel assembly 2 arranged in the cavity is fixed on the inner wall of the cavity through the bottom plate 13 of the positive pressure effusion tank. Several first elongated holes 211 on the liquid barrel assembly 2 communicate with the inner and outer sides of the liquid barrier barrel assembly 2, and the vent pipe assembly 1 communicates with the i...

Embodiment 2

[0074] The present invention also proposes another embodiment to perfect the application during the specific implementation process, specifically, it also includes a magnetostrictive liquid level gauge assembly 7, and the magnetostrictive liquid level gauge assembly 7 is set through the top cover 41 The liquid level gauge slot 413 is inserted in the liquid level gauge groove 25 arranged on the inside of the overnight barrel 21 .

[0075] Further, the magnetostrictive liquid level gauge assembly 7 includes a magnetostrictive liquid level gauge 71, a magnetostrictive liquid level gauge bottom plate 72 and a magnetostrictive liquid level gauge fixing plate 73, the magnetostrictive liquid level gauge The gauge bottom plate 72 is a thin plate with a hole in the middle and can be put into the liquid level gauge tank 25. The magnetostrictive liquid level gauge bottom plate 72 is fixed on the bottom of the magnetostrictive liquid level gauge 71 by bolts to ensure the magnetostrictive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com