Dovetail elongated slot milling tool and online monitoring system thereof

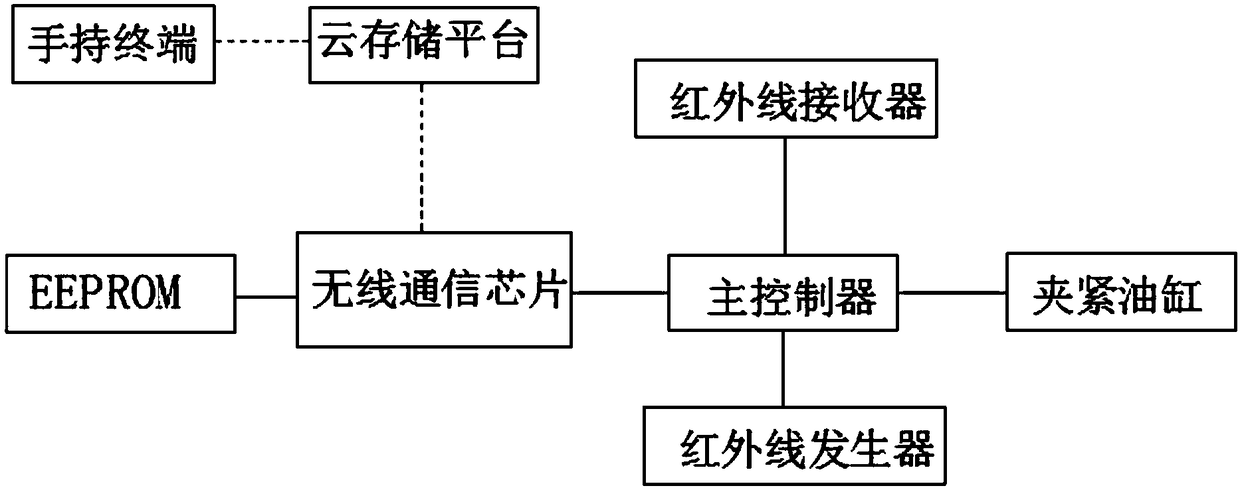

A monitoring system and long groove technology, applied in the field of mechanical processing, can solve problems such as poor clamping effect, waste of manpower and material resources, and slow down the maintenance process, so as to achieve the effect of facilitating remote control, saving manpower and material resources, and speeding up the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

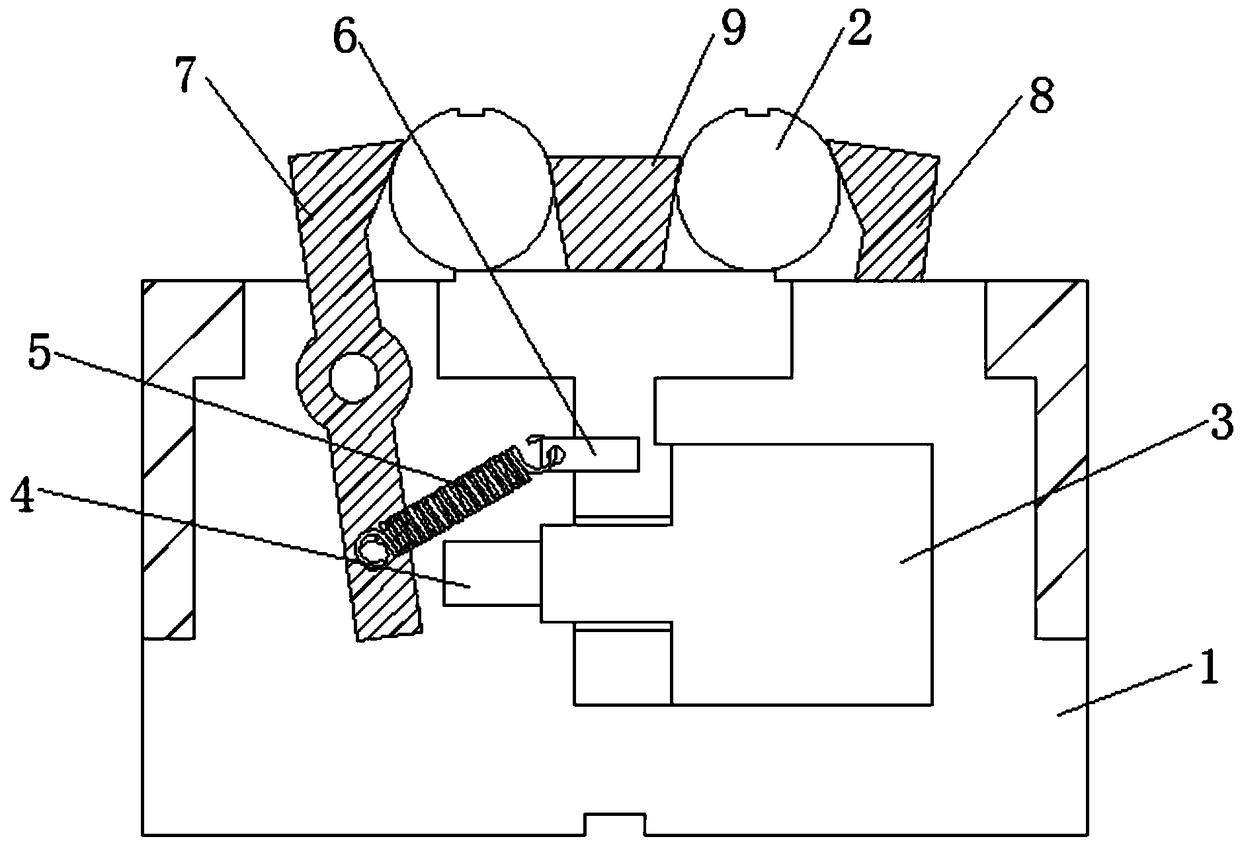

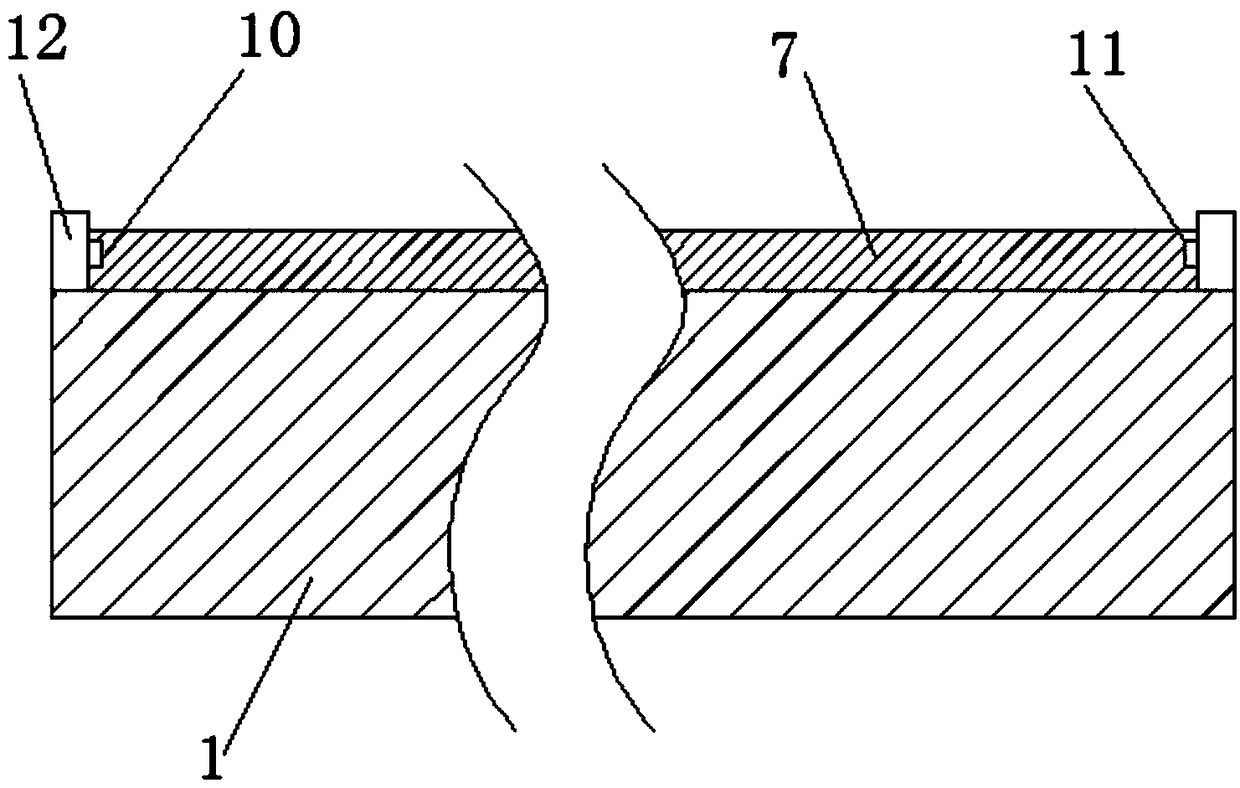

[0038] see figure 1 , a dovetail-type long slot milling tool, including a tooling seat 1 with a clamping cylinder 3 installed inside, a piston rod 4 connected to the power output end of the clamping oil cylinder 3, a pressure plate is provided on the inner side of the tooling seat 1, and the middle part of the pressure plate is rotatably connected with a Rotating shaft, both ends of the rotating shaft are connected with the inner wall of the tooling seat 1, the upper end of the pressing plate extends to the upper side of the tooling seat 1, the inner end of the tooling seat 1 is connected with a fixed plate 6, and a tension spring 5 is connected between the fixed plate 6 and the lower end of the pressing plate, The upper end of the tooling seat 1 is fixedly connected with the dovetail surface intermediate seat 9, and the workpiece 2 is placed on the upper side of the tooling seat 1, and the workpiece 2 is located between the dovetail surface intermediate seat 9 and the pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com