Feeding mechanism of full-automatic packaging machine and adjusting assembly

The technology of a fully automatic packaging machine and feeding mechanism is applied in the directions of transportation, packaging, roller table, etc. It can solve the problems of inconvenient adjustment of the height of the feeding platform, inability to adapt to various packaging machines, inconvenient assembly, disassembly and maintenance, etc., to increase labor. Efficiency, reducing the occupied space, preventing the effect of shaking things

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

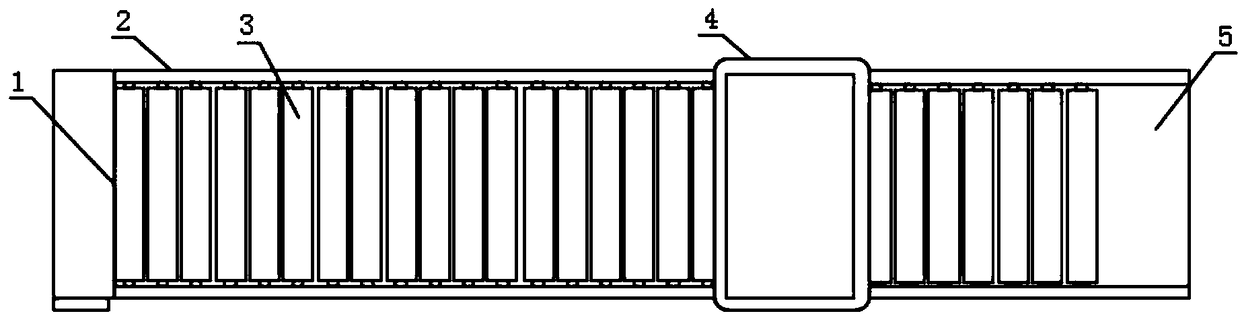

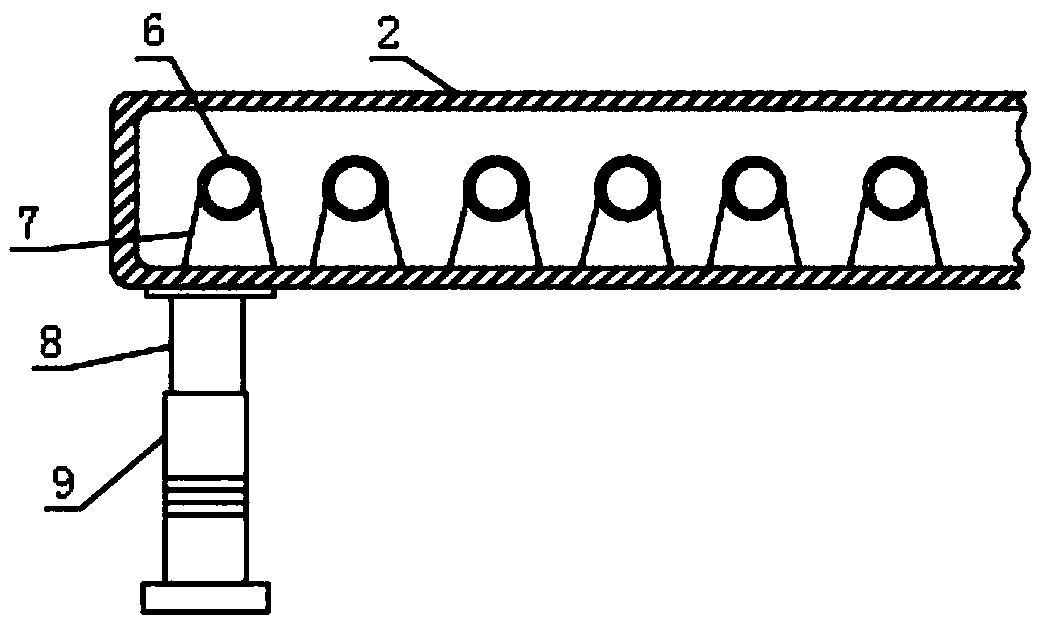

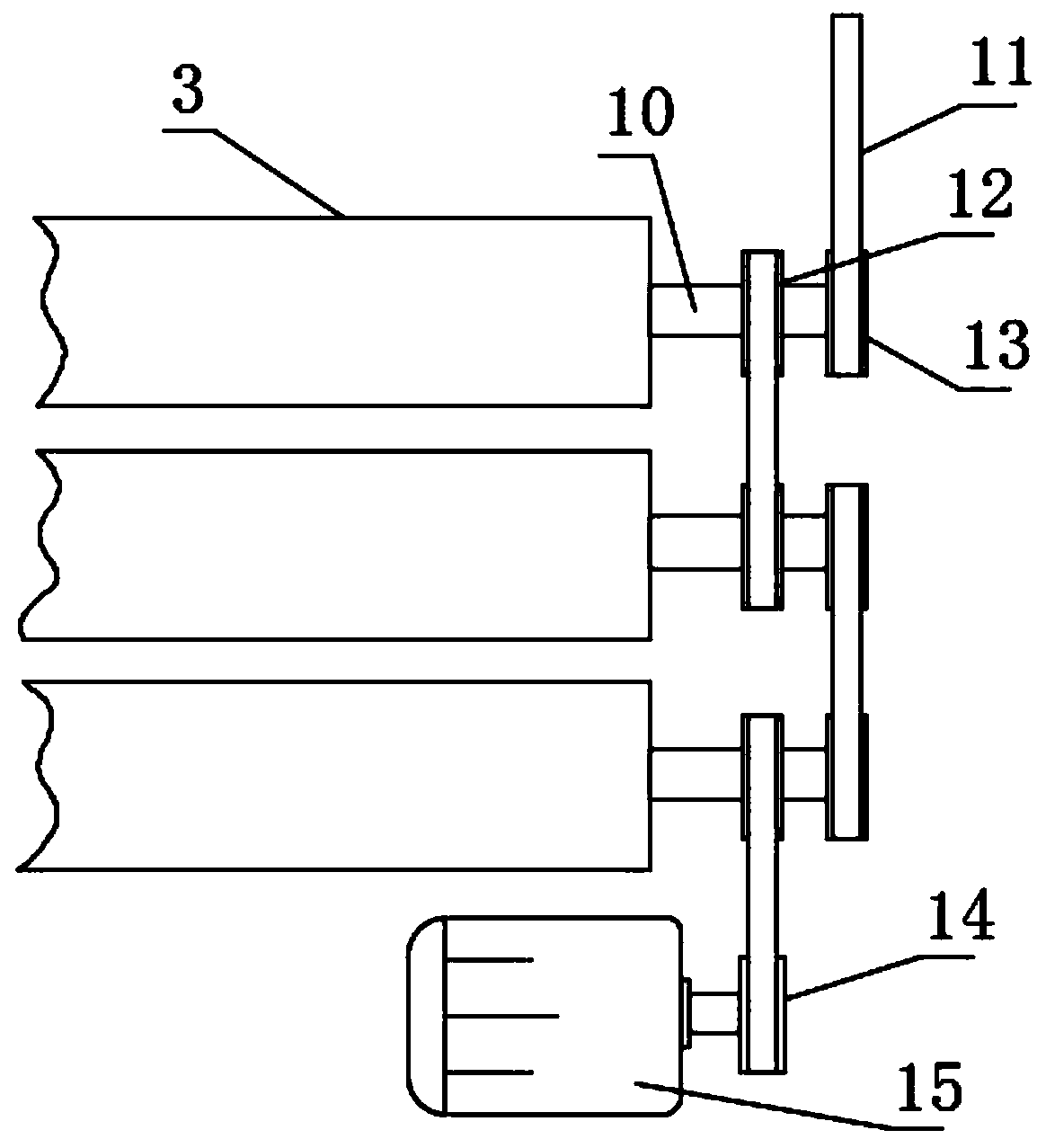

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a feeding mechanism and adjustment assembly of a fully automatic packaging machine, including a support frame 2, a packaging machine main body 4 and a support mechanism on the lower side of the support frame 2, and a conveying mechanism is arranged inside the support frame 2, The conveying mechanism includes a roller 3, a bearing 6, a support plate 7, a fixed shaft 10, a connecting belt 11, a first round shaft 12, a second round shaft 13, a pinion shaft 14 and an M206-412 type motor 15, and the fixed shaft 10 is symmetrically installed and fixed At both ends of the drum 3, the first circular shaft 12 is sleeved and fixed at the middle of the surface of the fixed shaft 10, the second circular shaft 13 is sleeved on the end surface of the fixed shaft 10, and the support plate 7 is symmetrically installed and fixed on the support frame 2, the bearing 6 i...

Embodiment 2

[0034] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a feeding mechanism and adjustment assembly of a fully automatic packaging machine, including a support frame 2, a packaging machine main body 4 and a support mechanism on the lower side of the support frame 2, and a conveying mechanism is arranged inside the support frame 2, The conveying mechanism includes a roller 3, a bearing 6, a support plate 7, a fixed shaft 10, a connecting belt 11, a first round shaft 12, a second round shaft 13, a pinion shaft 14 and an M206-412 type motor 15, and the fixed shaft 10 is symmetrically installed and fixed At both ends of the drum 3, the first circular shaft 12 is sleeved and fixed at the middle of the surface of the fixed shaft 10, the second circular shaft 13 is sleeved on the end surface of the fixed shaft 10, and the support plate 7 is symmetrically installed and fixed on the support frame 2, the bearing 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com