Yarn with variable twist and spinning method thereof

A technology of twisting and weakly twisting yarn, applied in the field of spinning, can solve the problem that the thickness of the yarn cannot be maintained, and achieve the effect of facilitating the popularization and use and keeping the thickness consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A variable twist yarn, including a strong twist yarn section and a weak twist yarn section. The yarn composition of the variable twist yarn is short fiber pure spinning or multi-component blending. The yarn thickness of the variable twist yarn remains unchanged, and the twist of the yarn along the yarn The axis of the line changes;

[0024] The twist ratio of the strong twisted yarn segment to the weak twisted yarn segment is 1.2-1.8, and the length of the strong twisted yarn segment to the weak twisted yarn segment is 1m-20m;

[0025] The ratio of the twist size of the strong twist yarn segment to the weak twist yarn segment is 1.5;

[0026] The length of the strongly twisted yarn section and the weakly twisted yarn section is 10m.

Embodiment 2

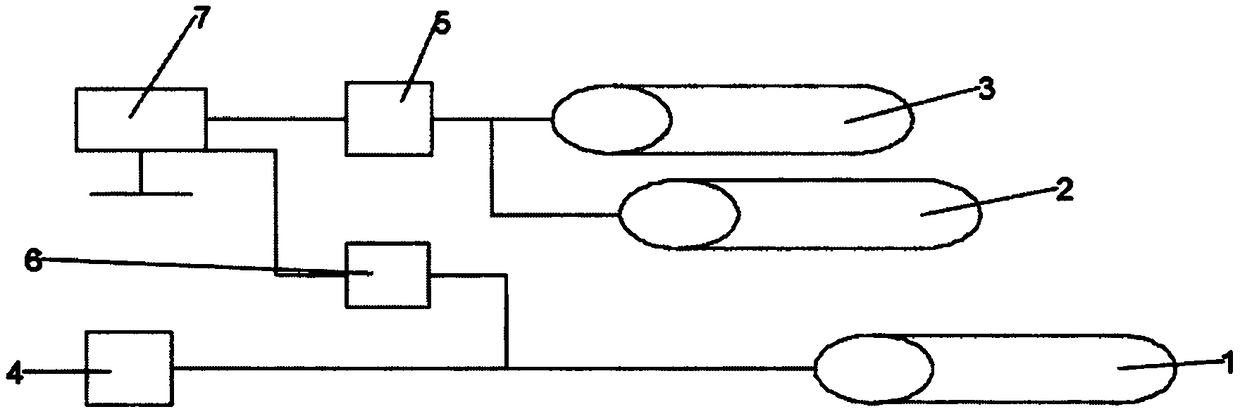

[0028] Depend on figure 1 As shown, in the embodiment of the present invention, a variable twist yarn production device based on the variable twist yarn described in Embodiment 1 includes a front roller 1, a middle roller 2 and a rear roller 3, and both the middle roller 2 and the rear roller 3 are connected with the servo The motor 5 is electrically connected, the servo motor 5 is electrically connected with the servo motor controller 7, the servo motor controller 7 controls the operation of the servo motor 5, the servo motor controller 7 is also electrically connected with the front roller speed tracking device 6, and the front roller The speed tracking device 6 is electrically connected to the front roller 1 in two directions;

[0029] The front roller 1 and the front roller speed tracking device 6 are also electrically connected with the main motor 4 .

Embodiment 3

[0031] A variable twist yarn spinning method based on the variable twist yarn production device described in embodiment 2, the steps are as follows:

[0032] S1. The fiber is processed into roving that meets the requirements through the pre-spinning process. The spun yarn is spun by a ring spinning frame equipped with a variable twist yarn control device. The ring spinning frame is spun into a siro spinning frame and a compact spinning spun yarn One of the spinning machines and Siro compact spinning frames;

[0033] S2. Disconnect the transmission between the drafting roller and the spindle of the spinning frame, install a servo motor 5, and control the servo motor 5 to run by a servo motor controller 7, drive the drafting roller, and the original motor of the spinning frame drives the spindle;

[0034] S3. According to the process design, the output line speed of the front roller 1 is driven by the servo motor controller 7 to produce speed changes, and the spindle speed remai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com