Cross shaft with temperature and vibration monitoring device

A monitoring device and vibration monitoring technology, which is applied to measuring devices, parts of thermometers, vibration measurement in solids, etc., can solve problems such as damage, unsmooth transmission, and shortened service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

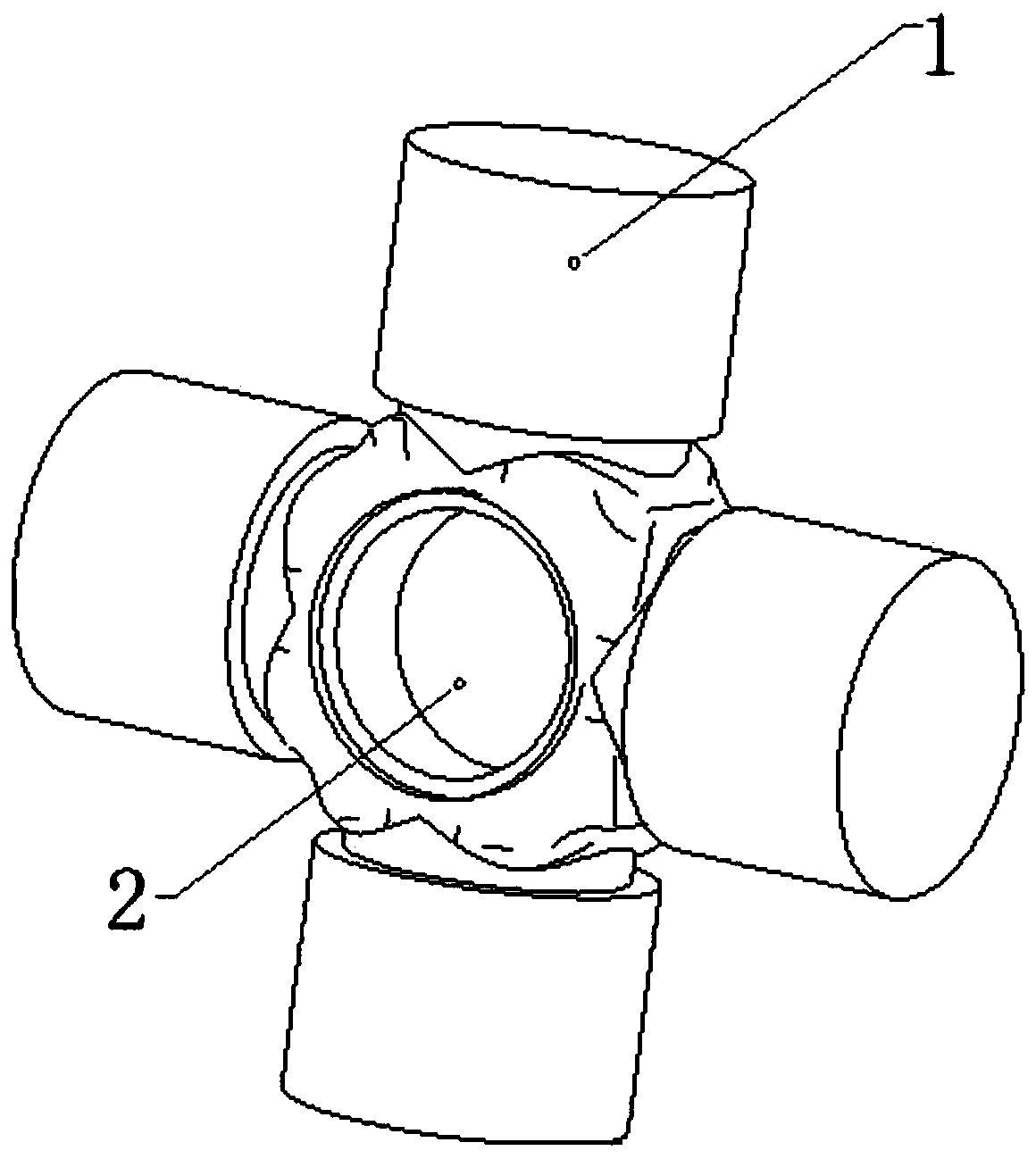

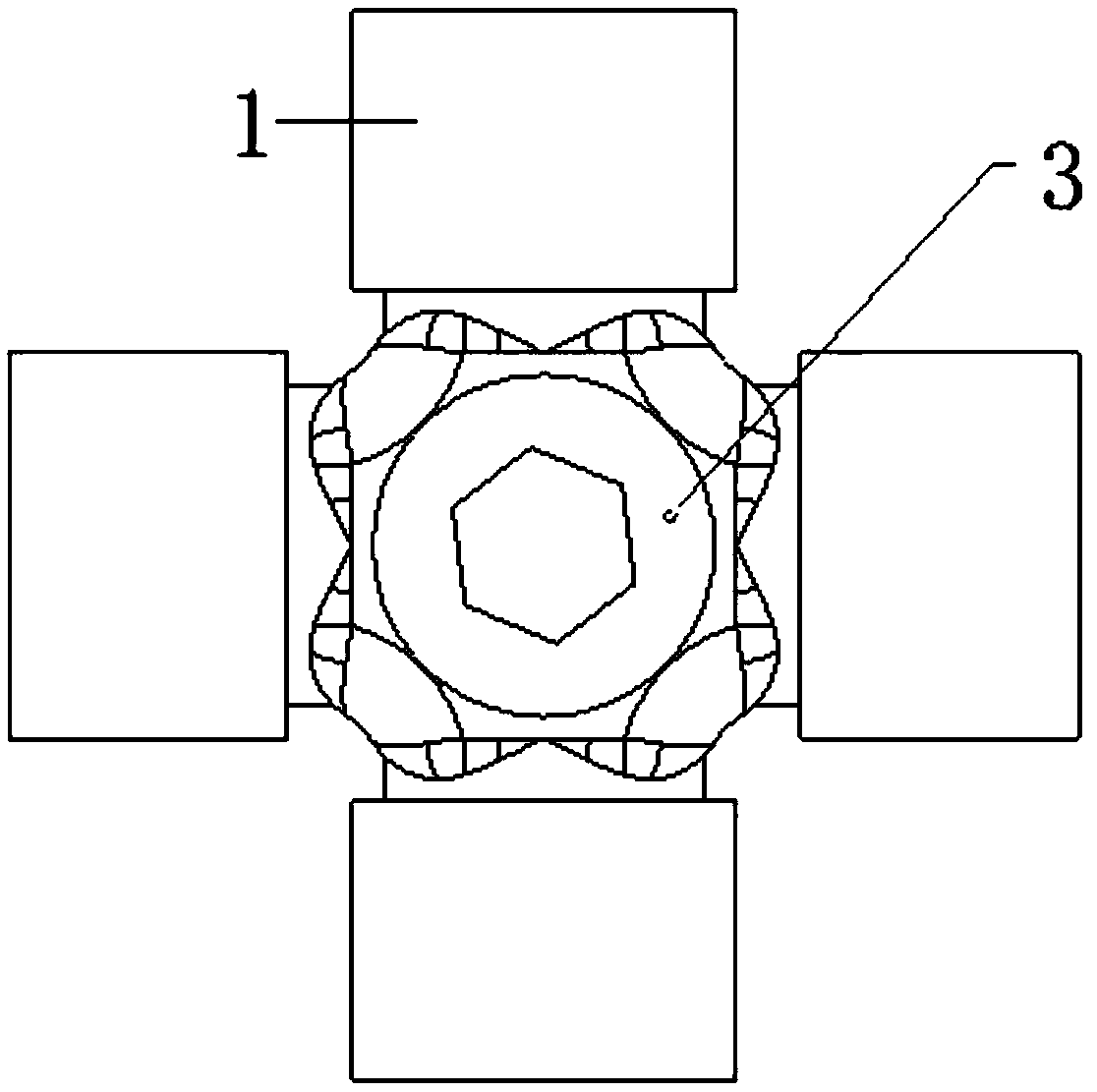

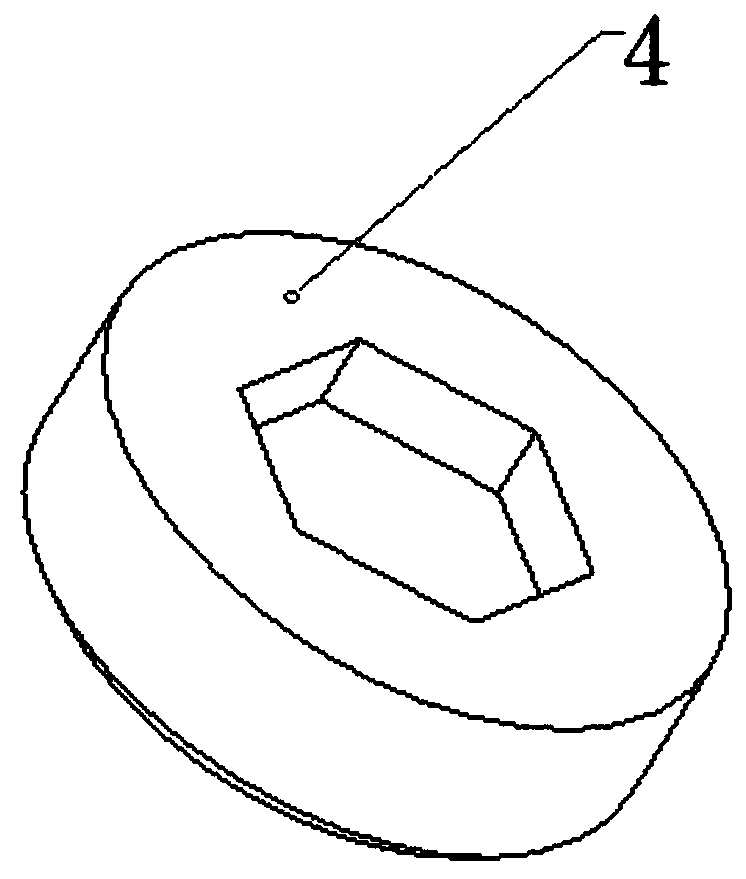

[0031] like Figure 1-5 As shown, the present invention installs a sensor 3 in the sensor mounting hole 2 in the universal joint 1, the sensor integrates temperature and vibration monitoring devices, and converts, transmits, and wirelessly transmits the detected signals; the sensor can be internally Hexagonal shape sensor 4, cylindrical shape sensor 5, external hexagonal and cylindrical shape sensor 6 various shapes, here when the device is used on the universal joint, a related signal receiving and displaying alarm device is installed in the cab , so that the driver can find out the temperature state and vibration of the universal joint in time; it fills this technical gap, solves the problem that the temperature and vibration monitoring cannot be carried out on the rotating parts of the universal joint in the past, and avoids the problem caused by The high temperature caused by the wear of the universal joint of the vehicle and the various serious consequences caused by the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap