Integrated measuring instrument for tapered roller

A technology of tapered rollers and measuring instruments, which is applied in the direction of instruments, measuring devices, electromagnetic measuring devices, etc., can solve the problems of slow comprehensive detection speed, cumbersome and complicated inspection process, and can not meet the needs of online production inspection, so as to improve the online inspection speed , to ensure continuity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

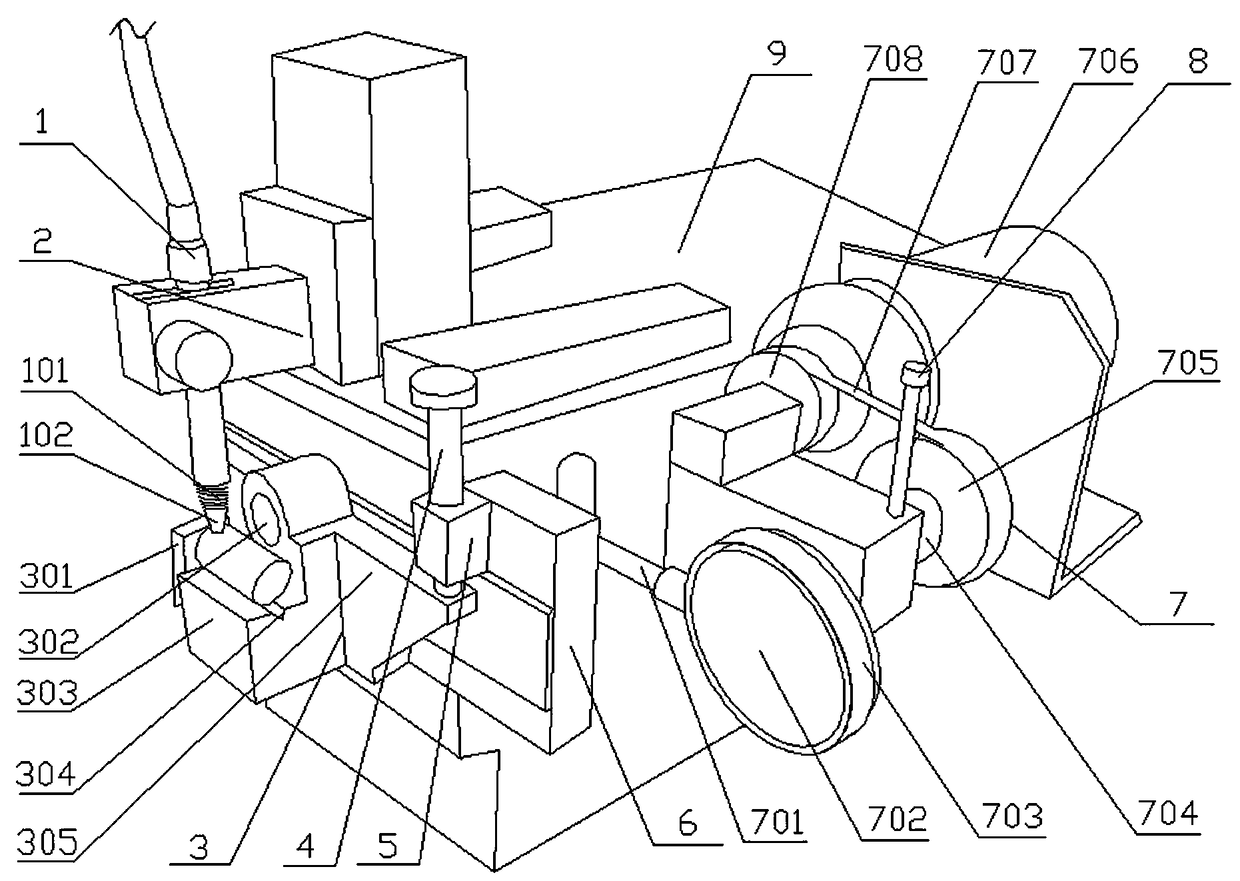

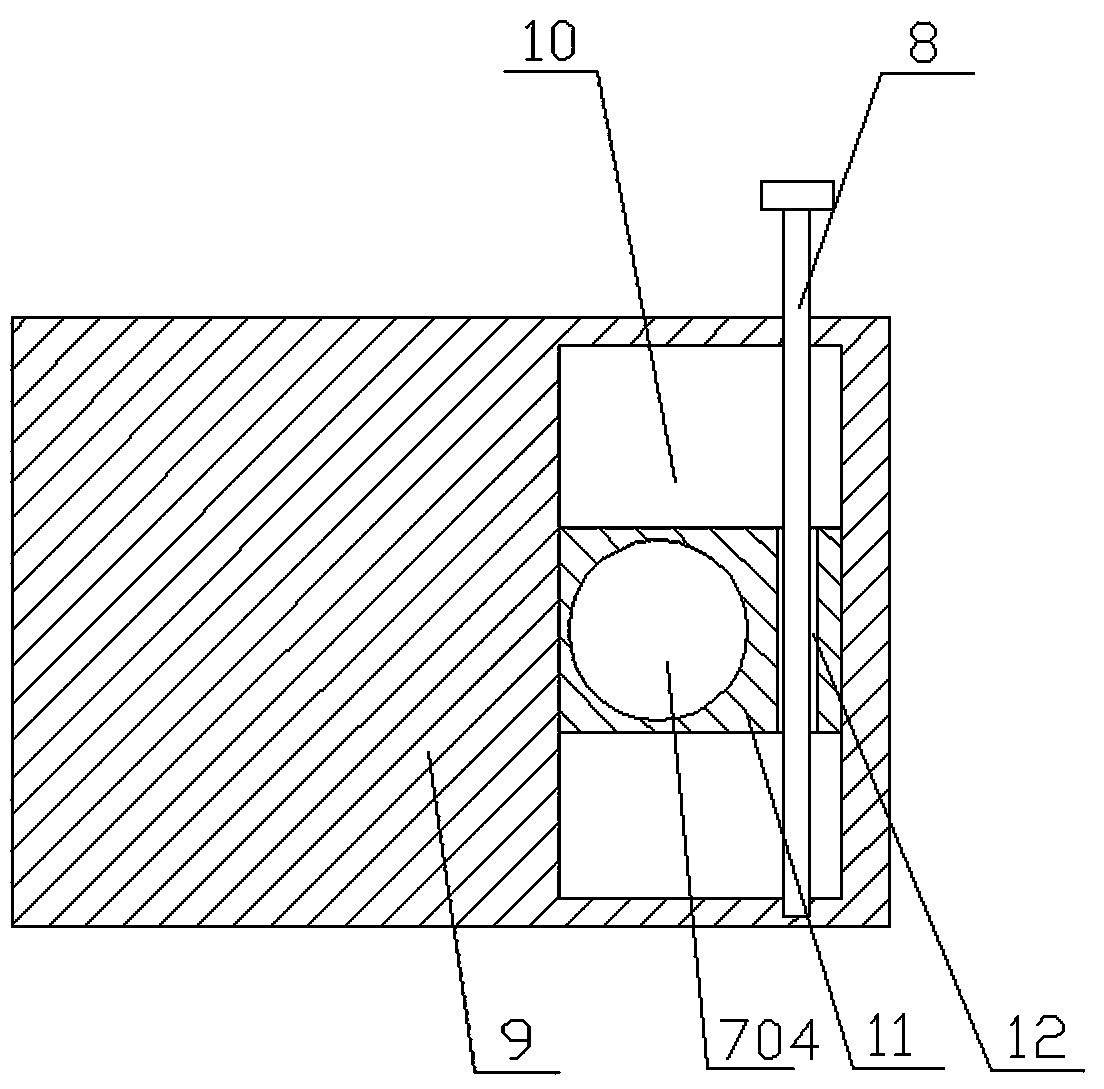

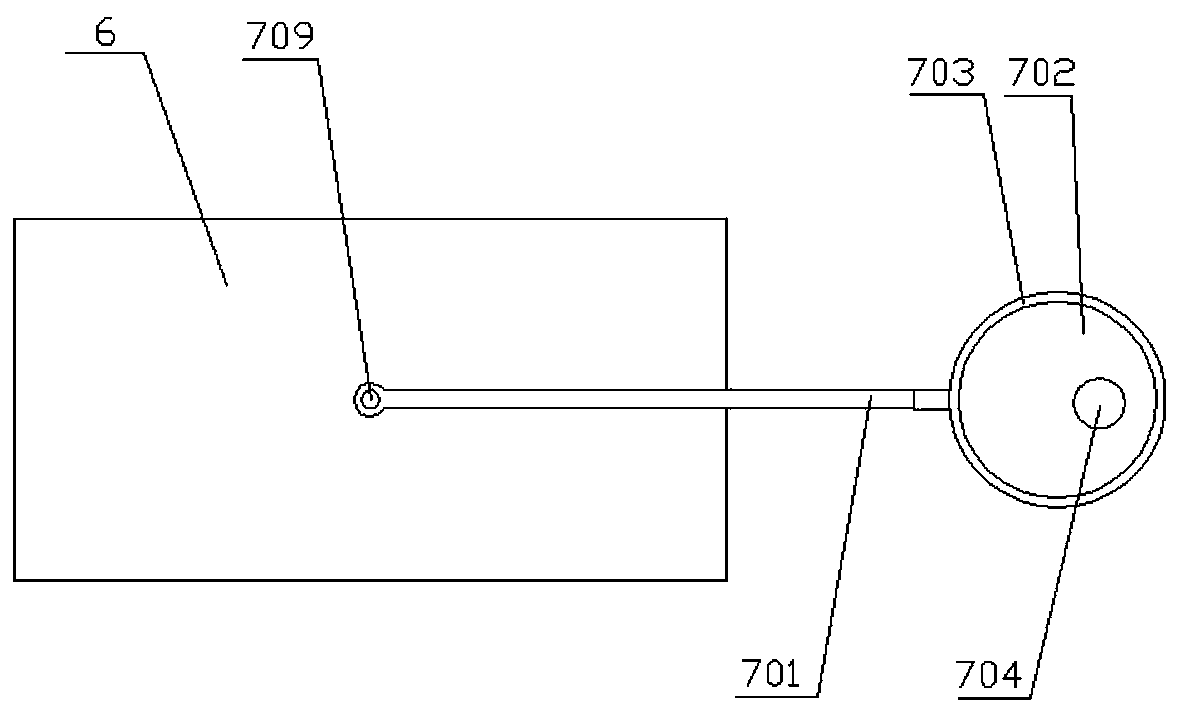

[0020] Such as figure 1 As shown, a tapered roller comprehensive measuring instrument of the present invention includes a rectangular frame 9 . On the top of the frame 9 and near the left end side, there are contact electric sensors 1 distributed along the vertical direction. The upper part of the contact electric sensor 1 is clamped and fixed on the second clamping tool 2, and the second clamping tool 2 is slidably arranged on the top of the frame 9, so that when the tapered roller to be tested is replaced, the measuring head 102 Stagger with the first clamping tool 3 to avoid damage to the measuring head 102 . The measuring head 102 of the contact electric sensor 1 is located at its lower end, and is used for measuring the geometric accuracy of the tapered roller. A slide plate 6 is provided on the side of the frame 9 below the contact electric sensor 1 . The slide plate 6 is distributed along the horizontal direction, and the side close to the frame 9 can slide left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com