Printed circuit board detecting method and system thereof

A technology for printed circuit boards and detection methods, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of PCB circuit damage and low production capacity of printed circuit boards, so as to increase productivity, improve online detection speed and time. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The features of the present invention can be clearly understood by referring to the drawings and the detailed description of the embodiments.

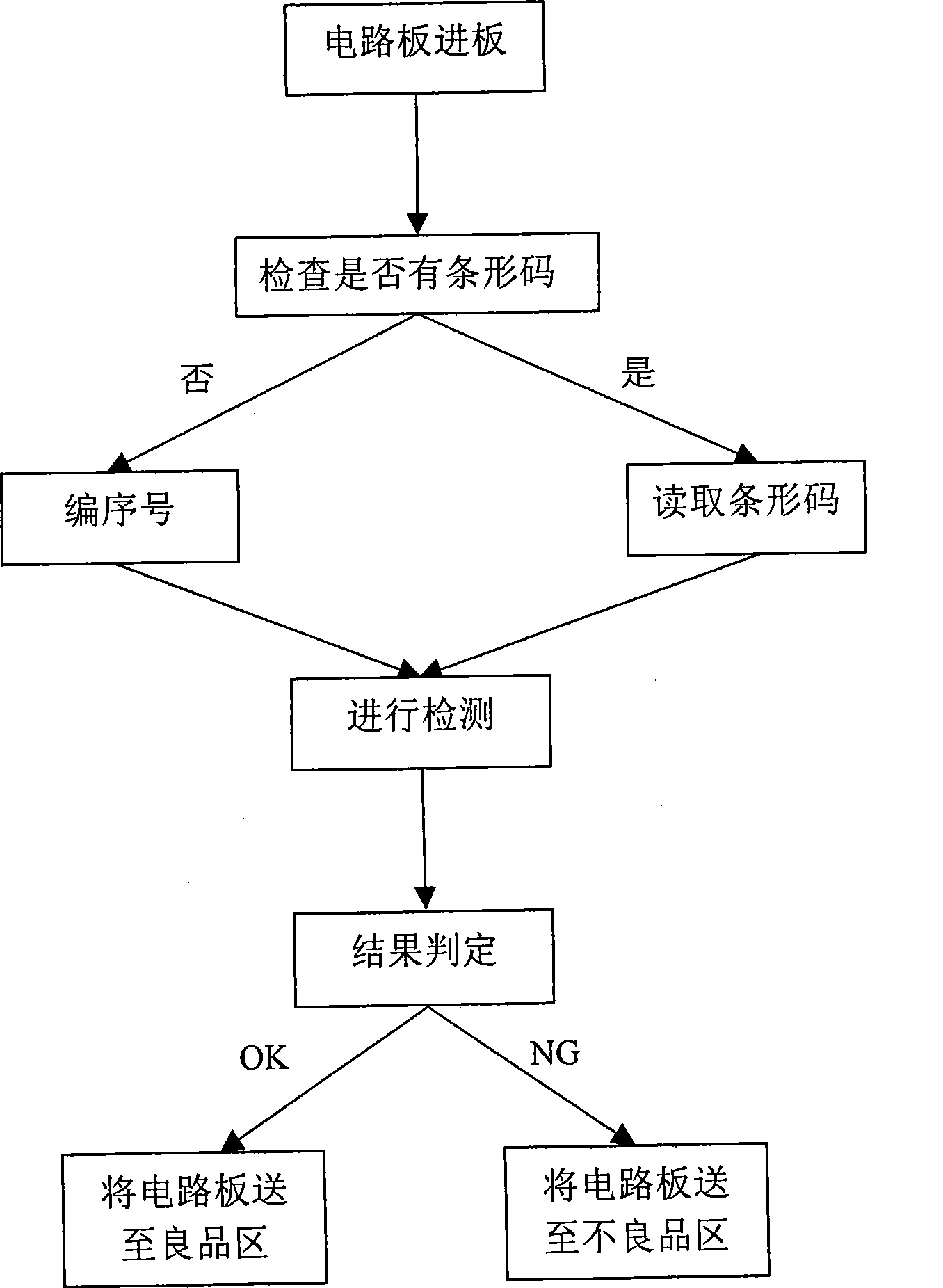

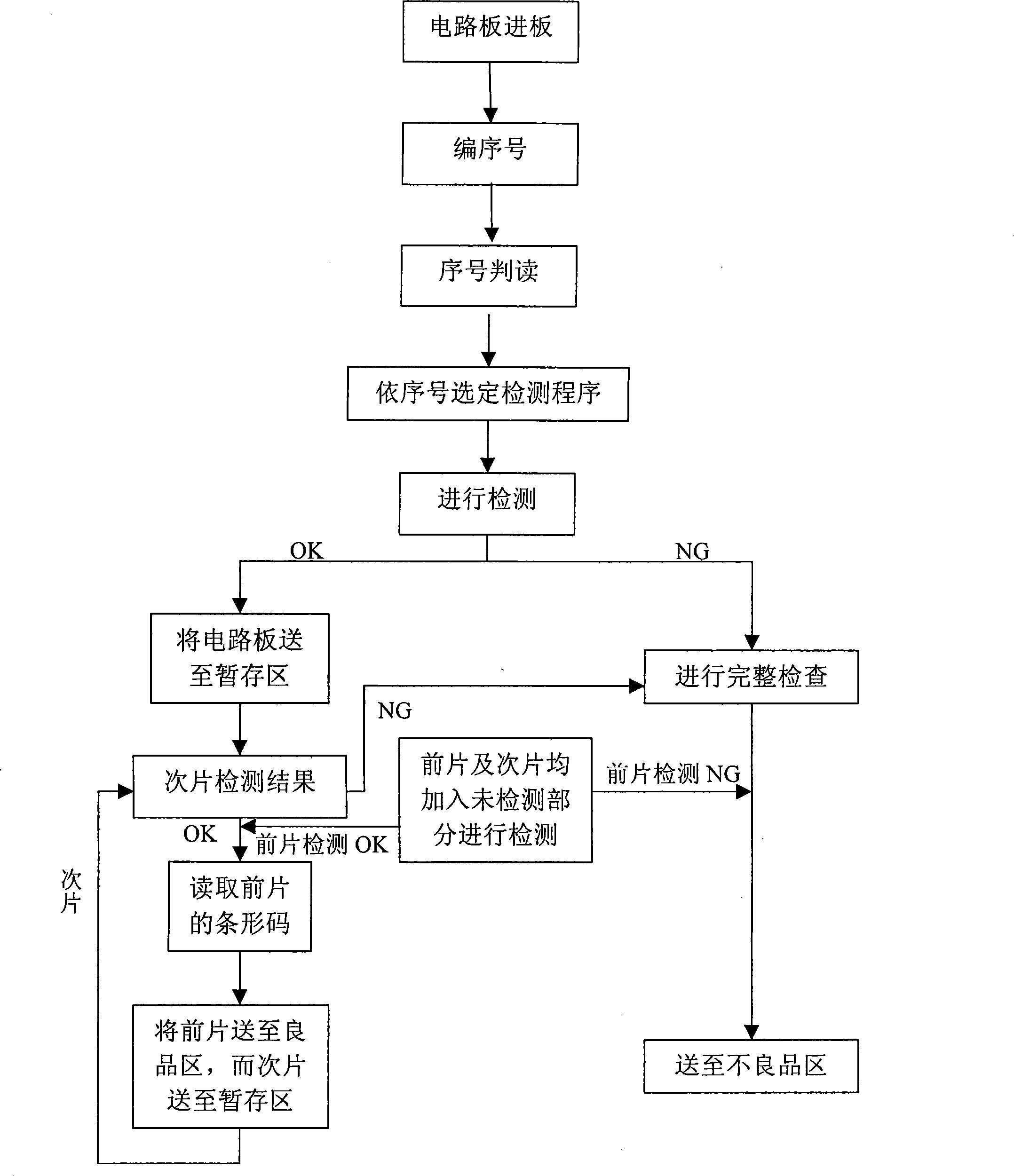

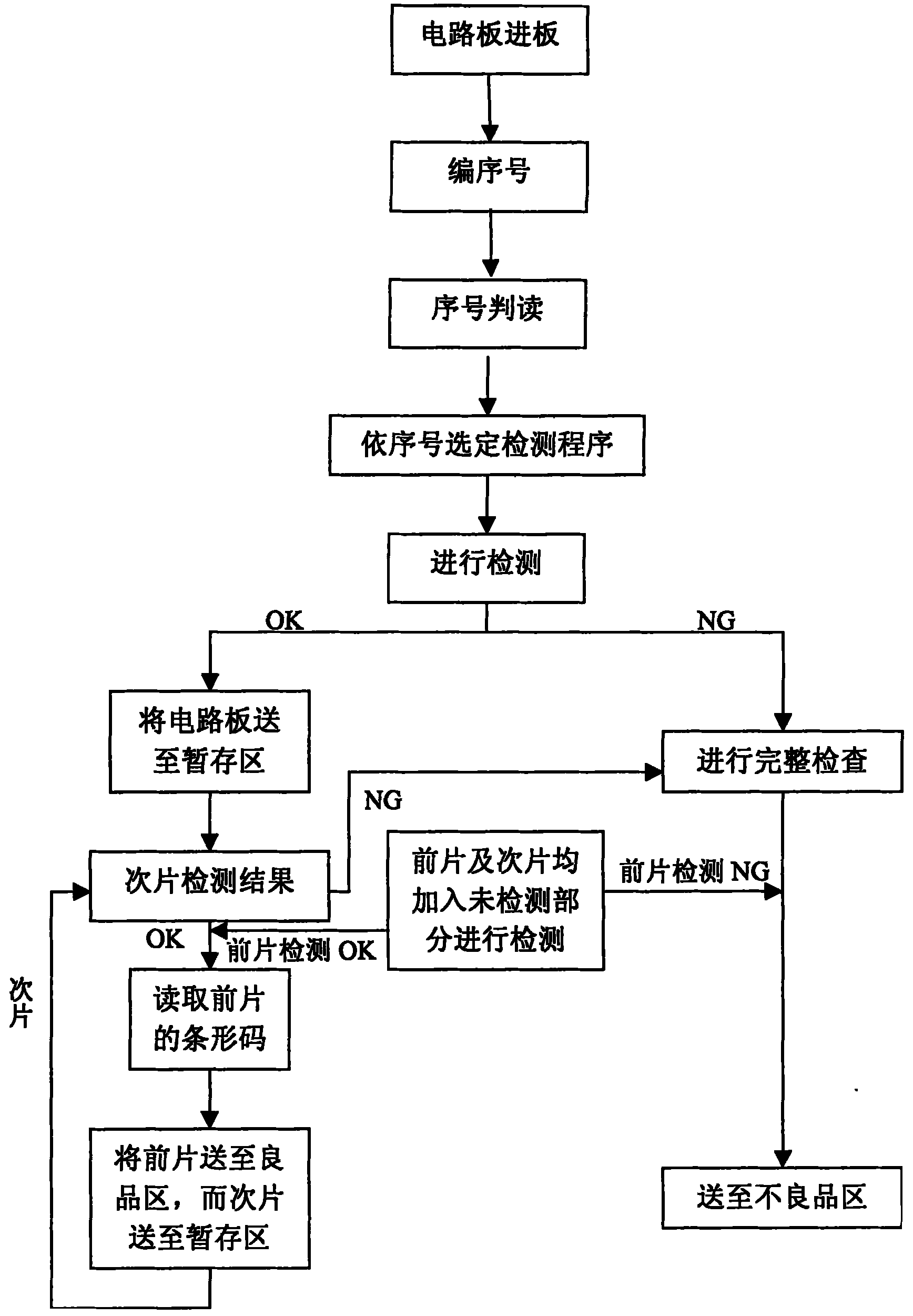

[0022] The printed circuit board inspection method of the present invention can select two modes of complete inspection or interval inspection of the printed circuit board, wherein the complete inspection is when the AOI inspection time is lower than the line balance time of the production line, and the complete inspection mode is selected to follow the existing tradition way to inspect the printed circuit board. If the AOI inspection time is longer than the line balance time of the production line, you can choose the interval inspection mode to shorten the inspection time, so you can switch between different inspection modes according to your needs.

[0023] Among them, the interval inspection mainly divides all test items on the printed circuit board into secondary test items and main test items, and the secondary test items a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com