Chip pin correction tooling and chip installation method

A chip mounting and chip technology, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. It can solve the problem of poor bonding between the solder on the surface of the PCB and the pins of the western chip, affecting soldering reliability, and inaccurate positioning. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

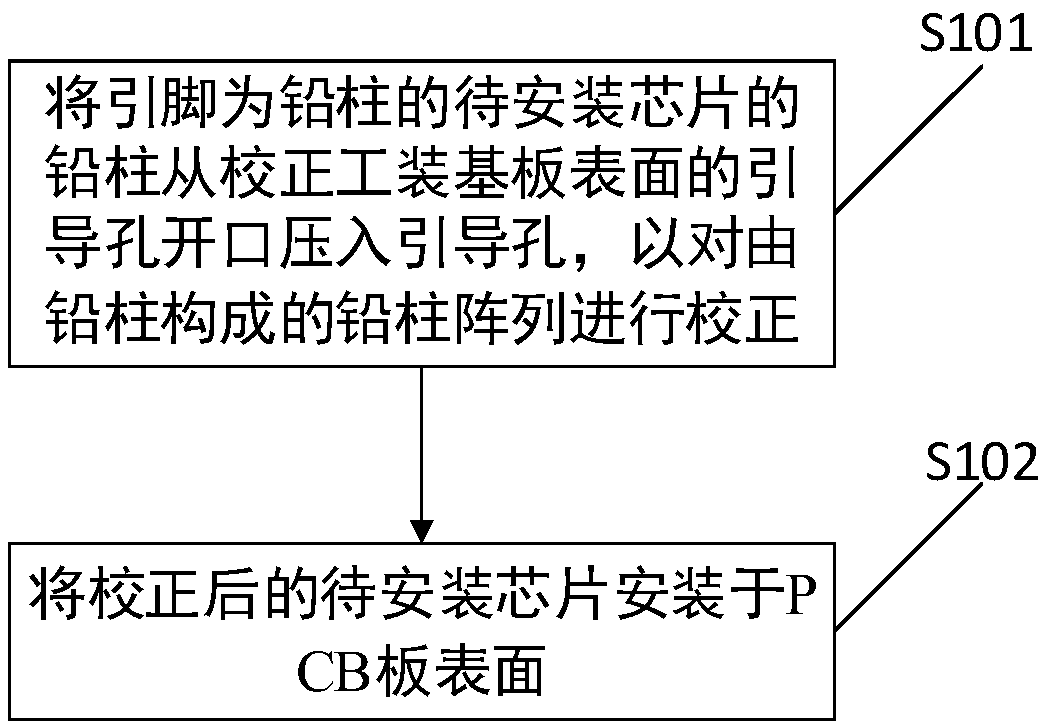

[0035] The core of the invention is to provide a chip lead correction tool. For chips with lead pins, the rigidity of the lead pins is poor, and the lead pins are prone to complete deformation and deflection during transportation and storage, so that there is no contact between the pins of the chip and the pads on the surface of the PCB. Precise positioning, resulting in poor bonding between the solder and the pins, which in turn leads to problems such as low solder joint strength, which affects the reliability of soldering.

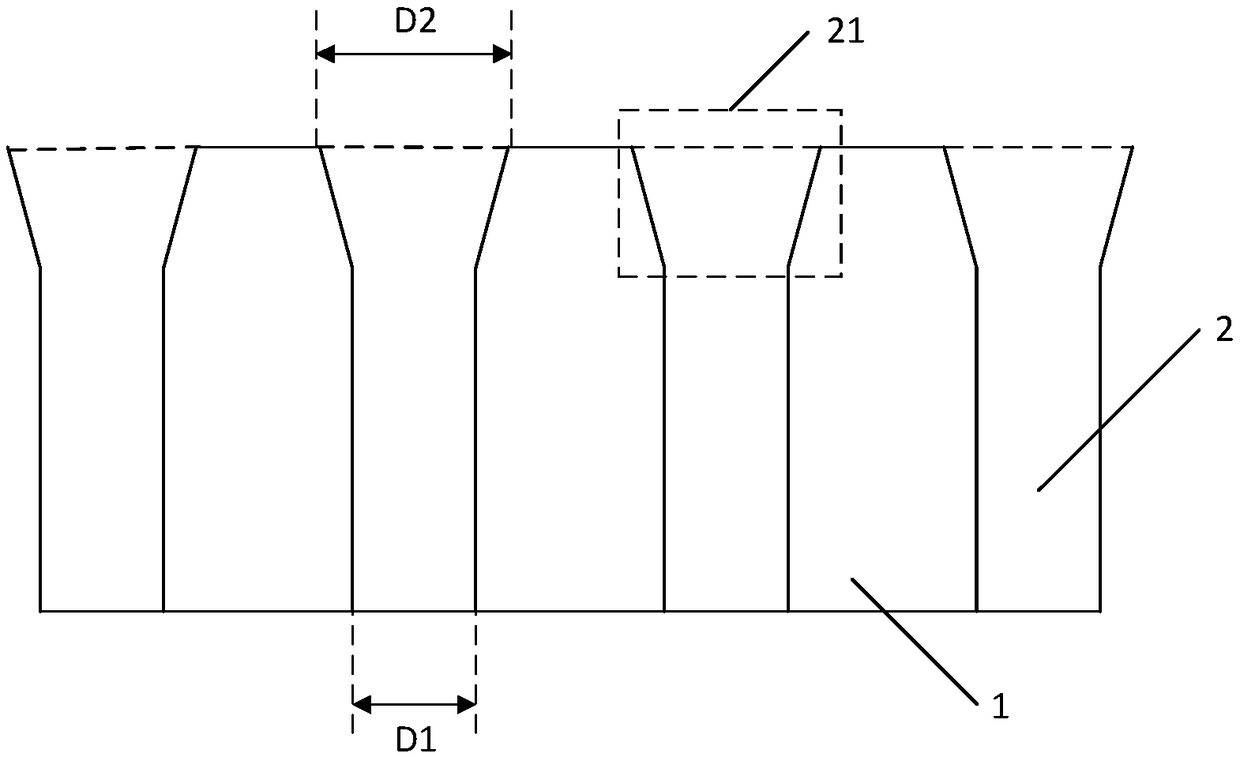

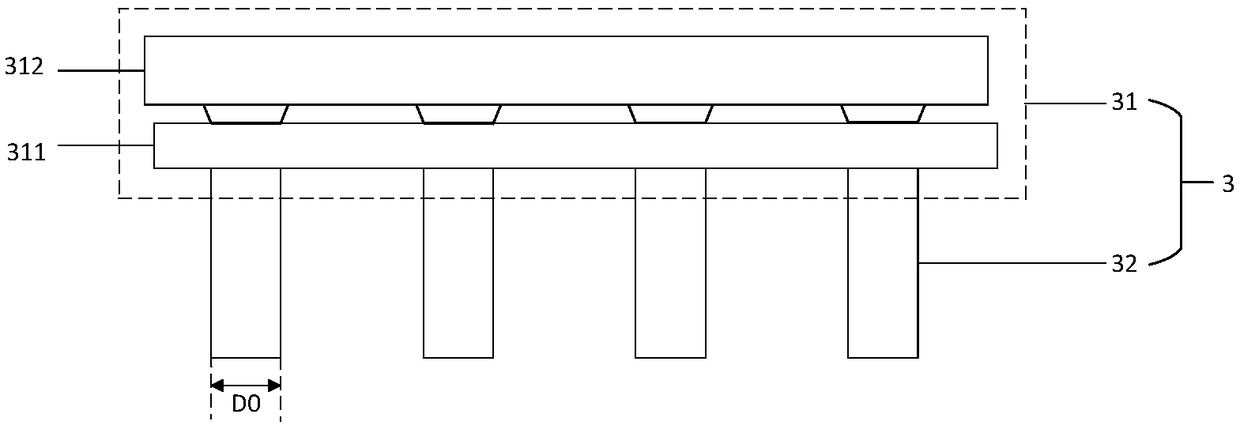

[0036] And a kind of chip lead correction tool provided by the present invention comprises a substrate and a guide hole positioned on the surface of the substrate; wherein the guide hole corresponds to the pin of the chip to be installed, and the lead of the chip to be installed is a lead post, and the lead post is in the The surface of the chip to be mounted forms a lead post array, and the guide holes form a guide hole array in the substrate, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com