A crushing device for a combine harvester

A technology of combine harvester and crushing device, applied in cutting equipment, agricultural machinery and implements, agriculture, etc., can solve problems such as damage to the rotating shaft drive device, accumulation of straw materials, and inability to continue the crushing operation, so as to alleviate or avoid blockage, The effect of strong continuous operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] like Figure 1-5 shown

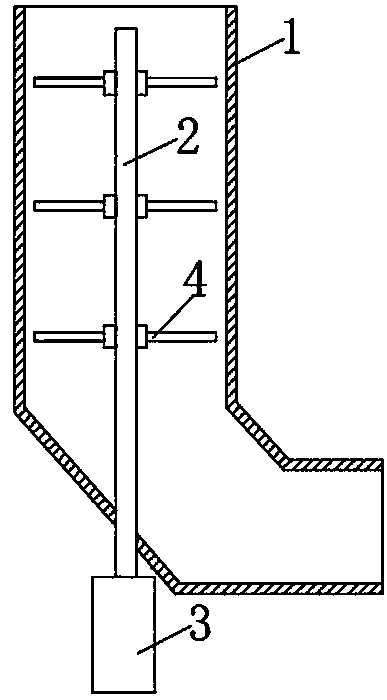

[0026] A crushing device for a combine harvester, comprising a cylindrical body 1, a rotating shaft 2 for setting the axis of the cylindrical body 1, a motor, a motor or other driving device 3 for driving the rotating shaft 2 to rotate, a cutter body 4, and a cutter body 4. A tool mounting mechanism 5 mounted on the rotating shaft 2. The tool mounting mechanism 5 is fixed on the rotating shaft 2 or is a part of the rotating shaft 2 by means of welding, integral molding, etc.

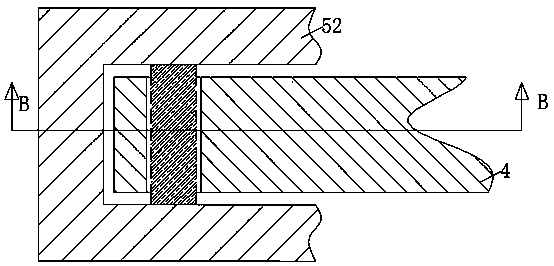

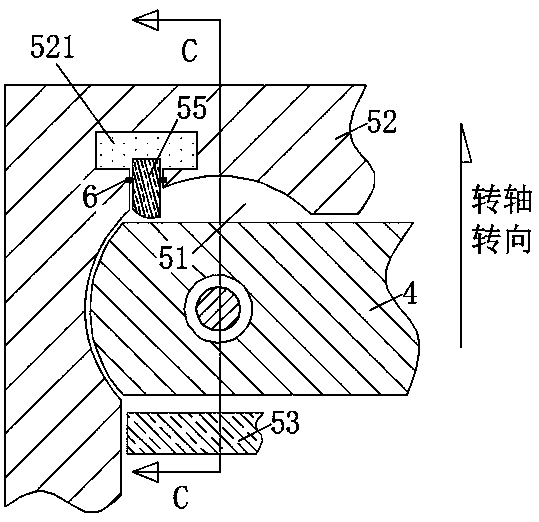

[0027] Further, the tool loading mechanism 5 includes a tool loading slot 51 and a slot body 52 with an opening facing the cylinder body 1 and a slot body 52 facing the opposite side of the rotation of the rotating shaft 2, and a baffle plate 53 arranged on the opposite side of the rotating shaft 2; inside the slot body 52 An oil pressure chamber 521 filled with grease is provided, the cutter body 4 is longitudinally hinged in the cutter slot 51, the baffle 53 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com