Control method of food processor

A technology of a food processing machine and a control method, which is applied to utensils with integral electric heating devices, overflow prevention, cooking utensils, etc. The effect of aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for controlling a food processor, the food processor may include: a cup body and a fan, the fan is used to accelerate the air flow in the cup body; figure 1 As shown, the method may include S101:

[0041] S101. After crushing the ingredients in the cup, continue to boil the ingredients, and turn on the fan, and control the speed of the fan to accelerate the air flow.

[0042] In the embodiment of the present invention, a continuous cooking stage can be added in the food processing process, and the fan is turned on while cooking, and the fan speed is controlled to speed up the air flow and prevent overflow.

[0043] In an embodiment of the present invention, the food processing process of the food processor, such as the pulping process, may include a preheating stage, a pre-crushing stage, and a one-time anti-overflow stage (the anti-overflow stage, that is, the slurry foam of the food once or several times) The stage of contacting the preset anti-overflow elec...

Embodiment 2

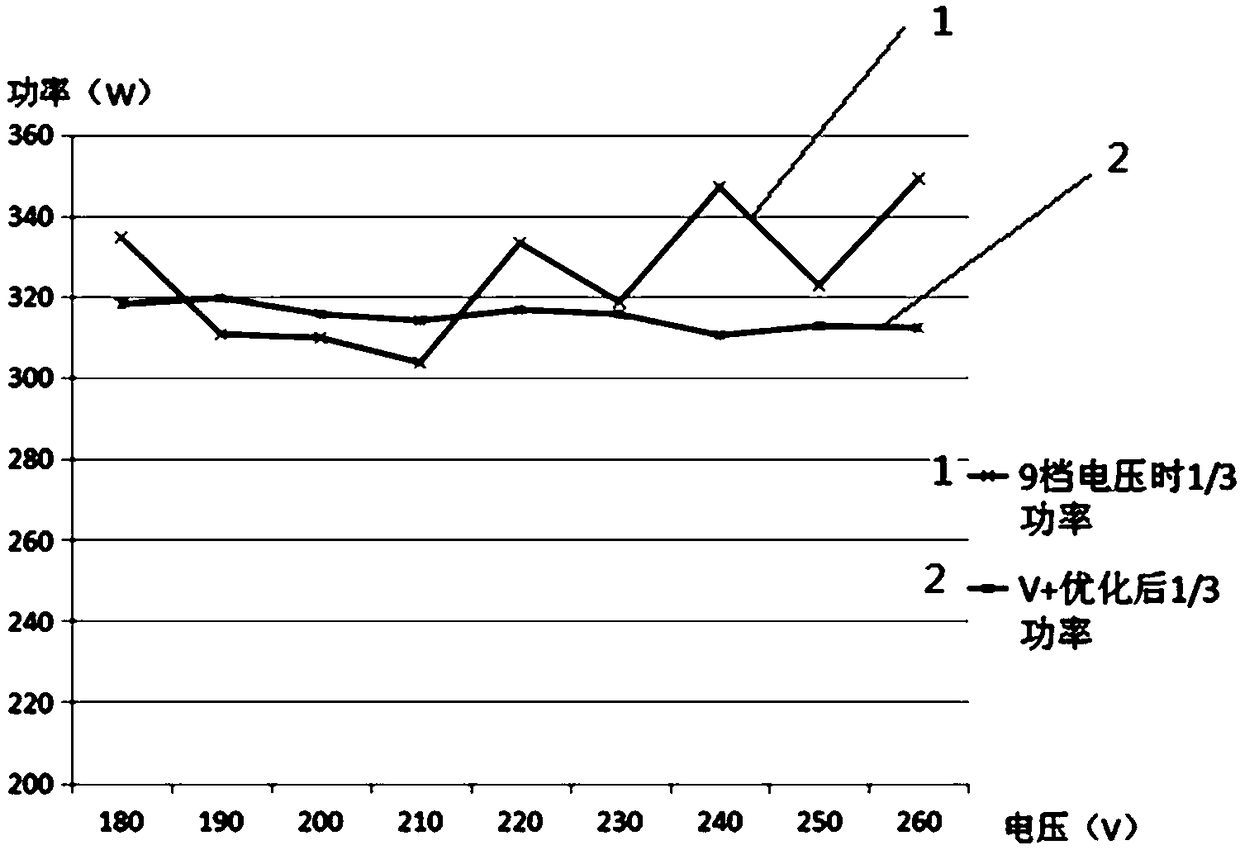

[0049] On the basis of Example 1, this example provides an example scheme in which different amounts of materials correspond to different heating powers and fan speeds in the continuous boiling stage.

[0050] Optionally, the method may also include:

[0051] Divide the material amount of the ingredients into gears, and adjust the heating power and fan speed during the continuous cooking process according to the different material amount gears of the material amount of the ingredients;

[0052] Wherein, the greater the amount of material, the higher the gear of the material amount; the higher the gear of the material amount, the greater the heating power and the higher the speed of the fan.

[0053] In the embodiment of the present invention, most of the current food processors have achieved wide-capacity pulping, ranging from 500-1300ml, with a maximum deviation of 800ml. In this case, if the same heating power is used in the continuous cooking stage And the fan speed, if th...

Embodiment 3

[0062] On the basis of the second embodiment, this embodiment provides specific corresponding embodiment schemes for different material amounts, different heating powers and different fan speeds.

[0063] Optionally, the material volume gears may include: a first gear, a second gear and a third gear:

[0064] The first gear may include: less than 700ml; the second gear may include: 700-1000ml; the third gear may include: more than 1000ml;

[0065] When the amount of the ingredients is in the first gear:

[0066] The heating power can meet: below 100W; the fan speed can meet: 1000-2500rpm;

[0067] When the amount of the food material is in the second gear:

[0068] The heating power can meet: 100-250W; the fan speed can meet: 2500-3500rpm;

[0069] When the amount of the ingredients is in the third gear:

[0070] The heating power can meet: 250-400W; the fan speed can meet: 3500-4500rpm.

[0071] In the embodiment of the present invention, the amount of material calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com