Knock-out barrel

The technology of a shakeout machine and a drum is applied in the field of foundry equipment, which can solve the problems of difficult collection of molding sand and diffusion of dust into the air, etc., and achieve the effects of improving impact resistance, reducing production costs of enterprises, and reducing water resources utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

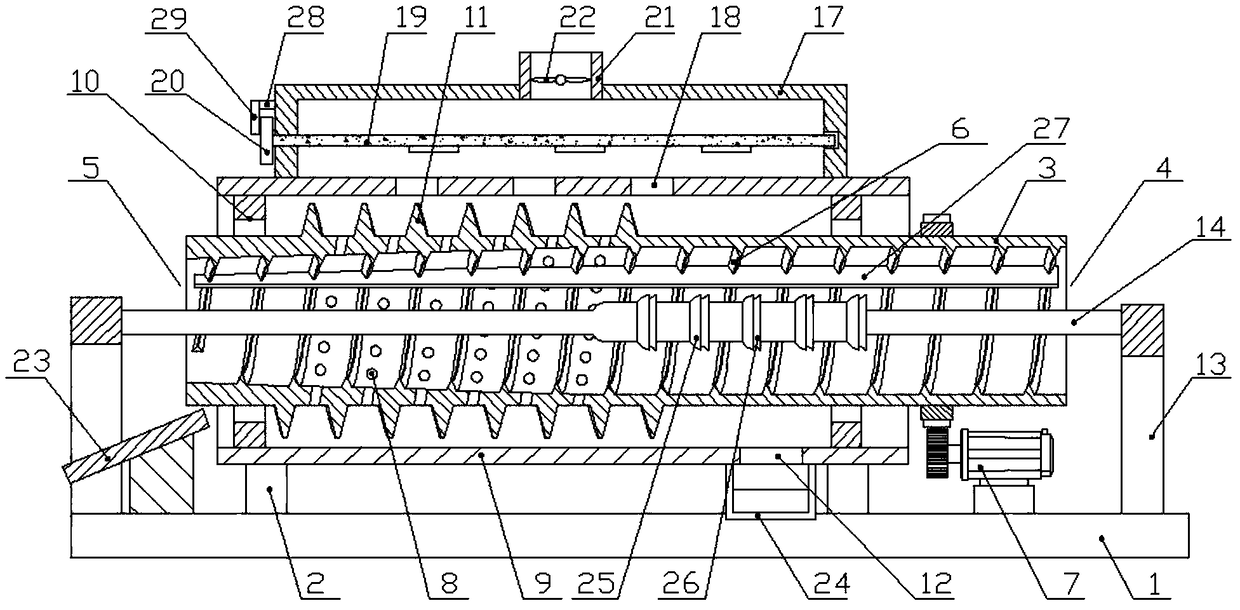

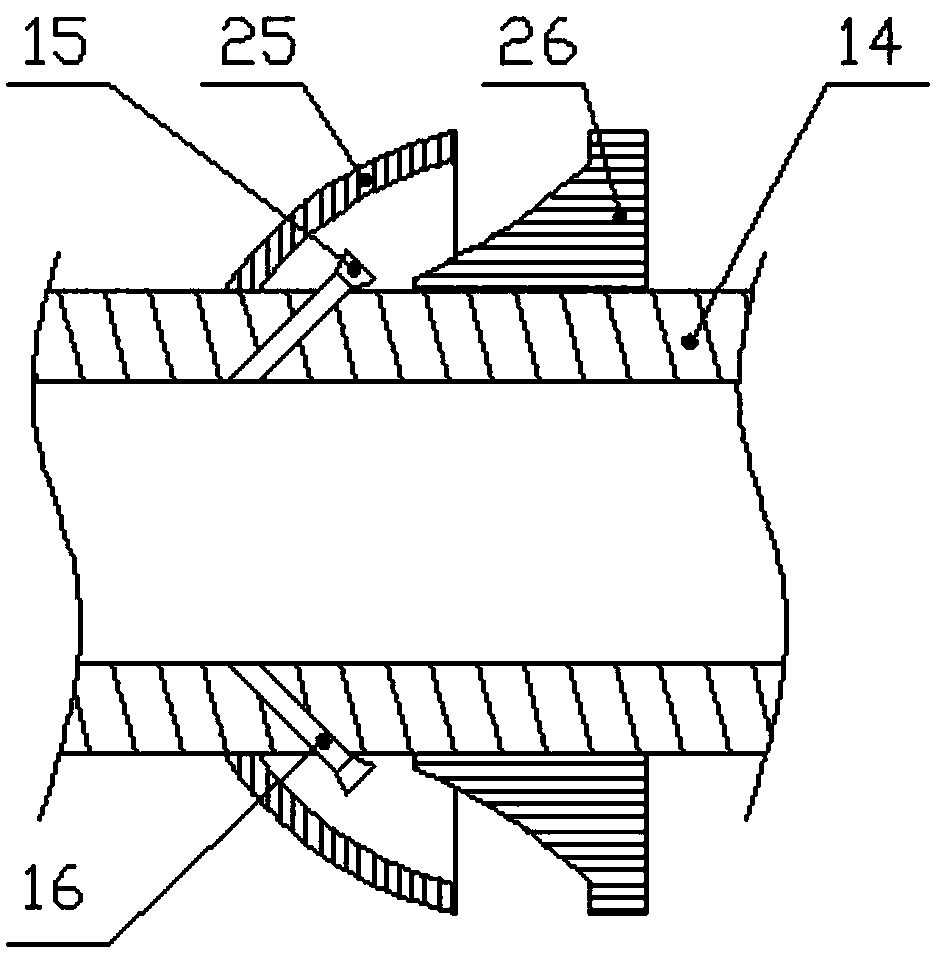

[0021] like Figure 1-Figure 2 As shown, the specific structure of the present invention is as follows: it includes a base 1, the middle part of the upper end of the base 1 is provided with a support seat 2 at intervals, and a cylindrical roller 3 is arranged above the support seat 2, and the two ends of the roller 3 are open. One end is set as the feed end 4, and the other end is set as the discharge end 5. The casting mold enters the drum 3 from the feed end 4, and the casting after falling out is discharged from the discharge end 5. The inner wall of the drum 3 is provided with an inner Thread 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com