Patents

Literature

34results about How to "Easy to blow to" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

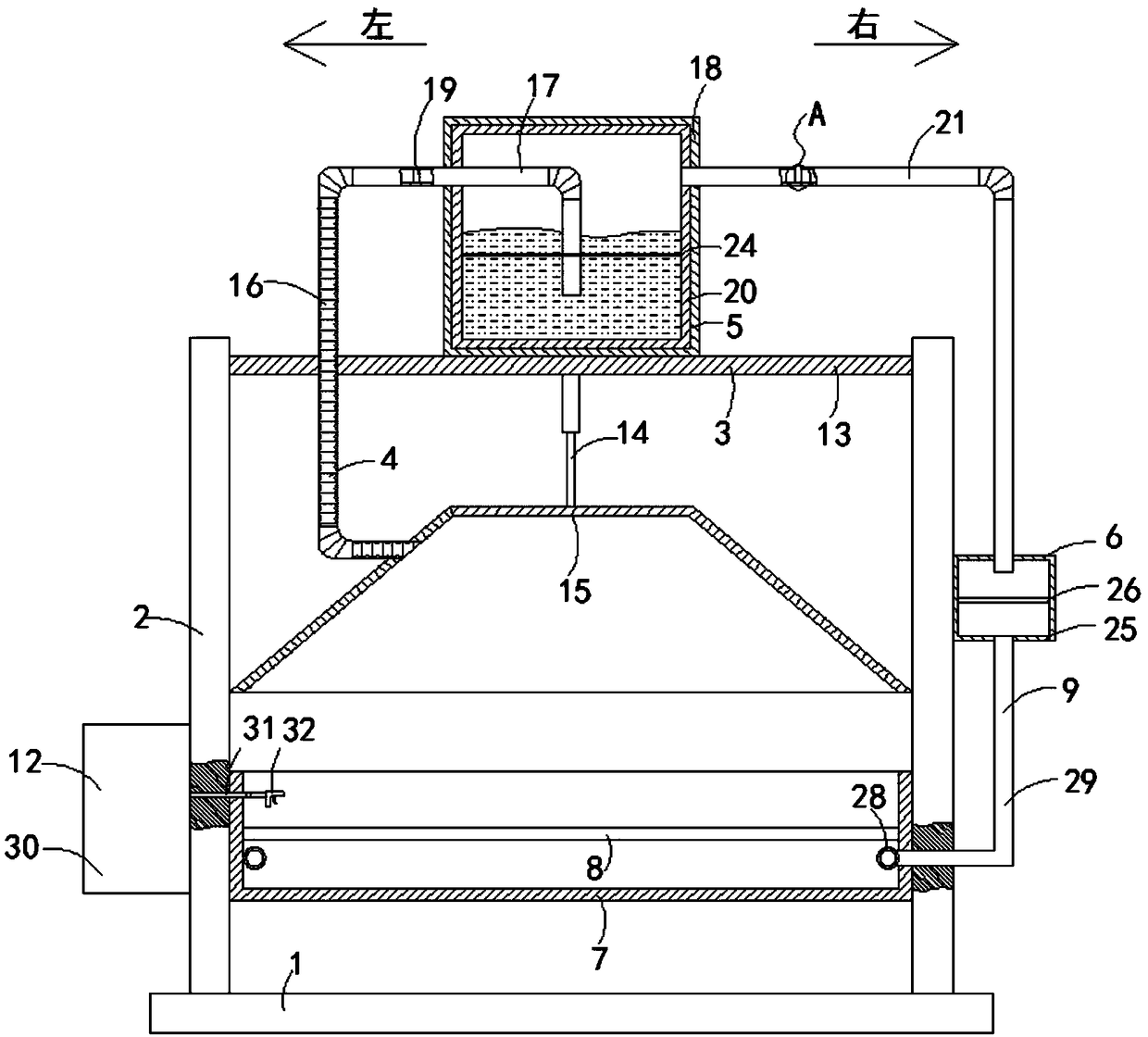

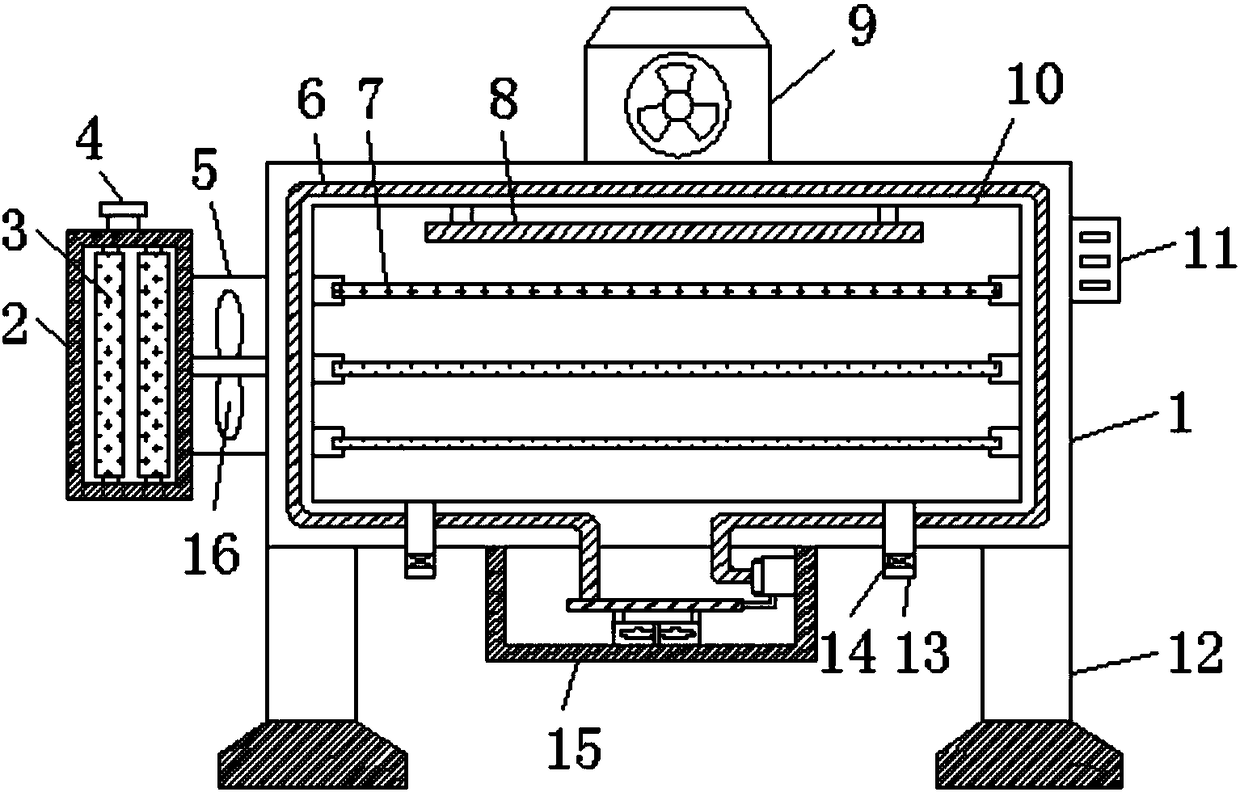

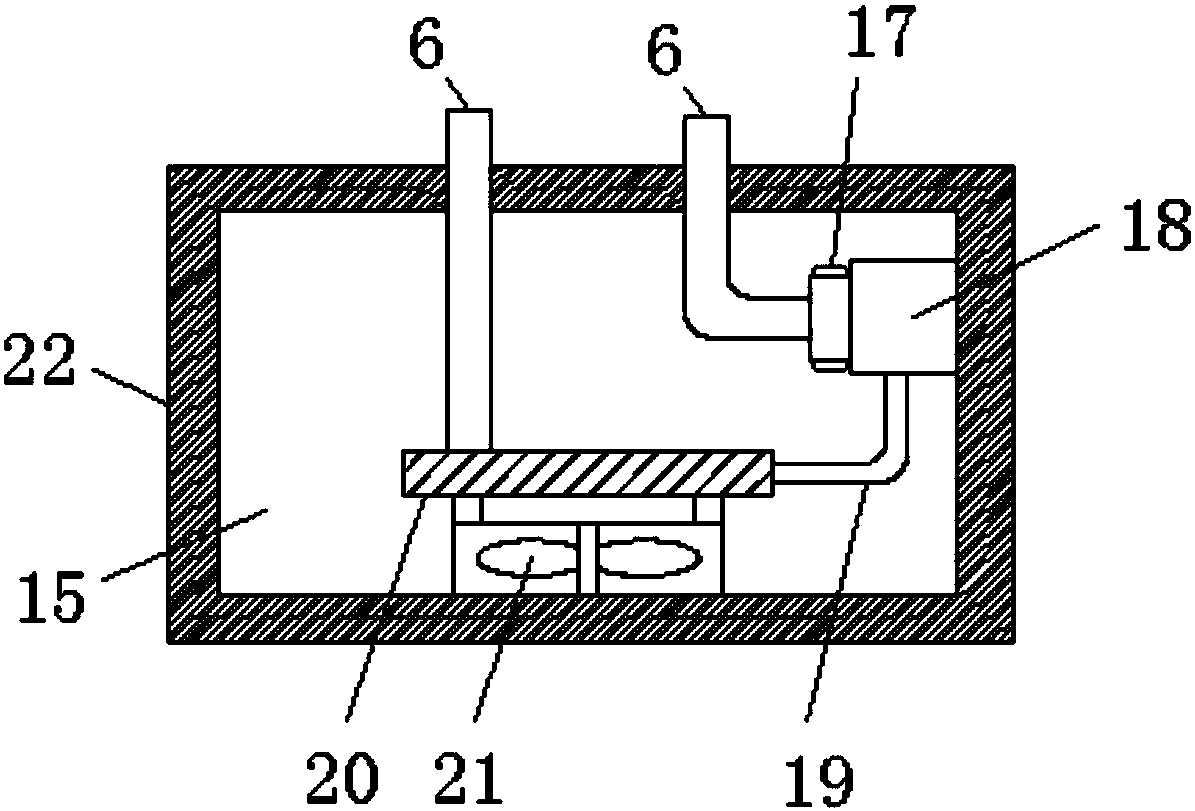

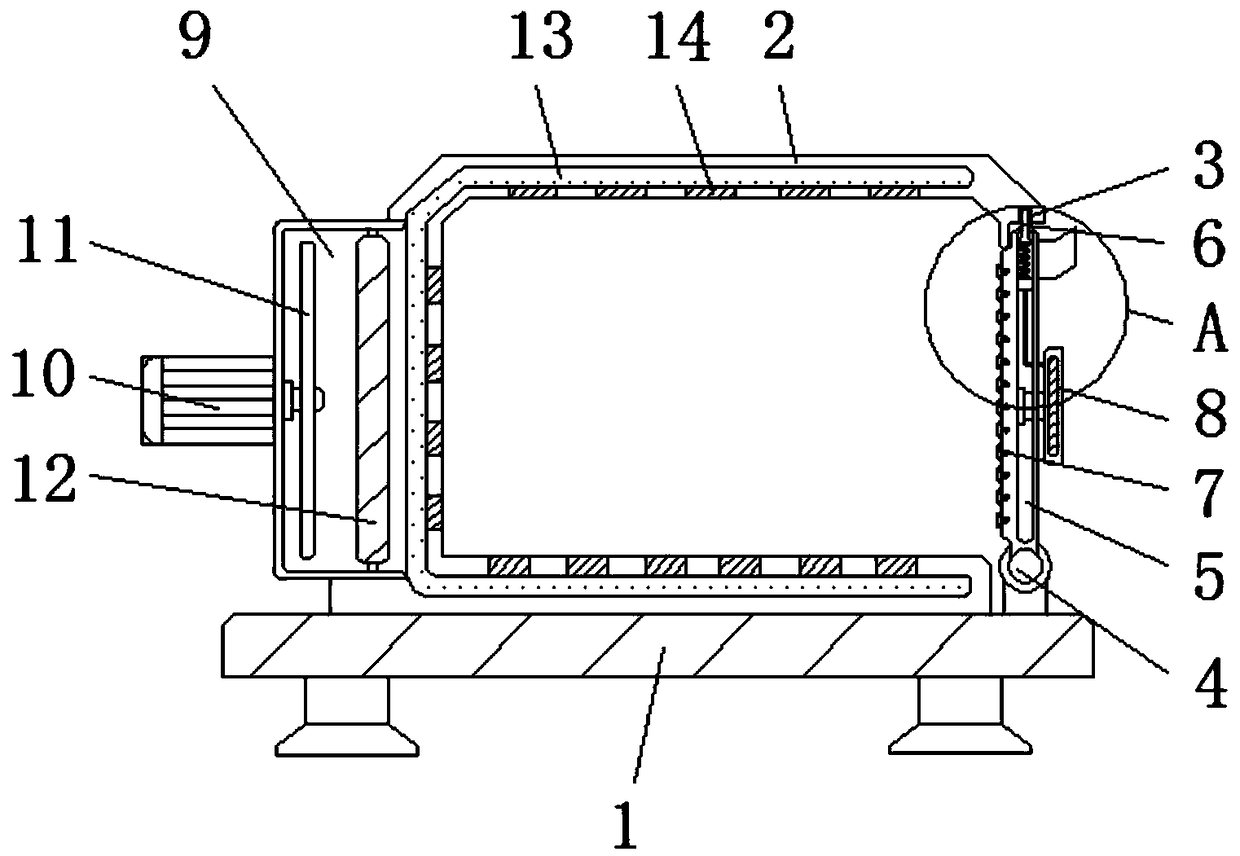

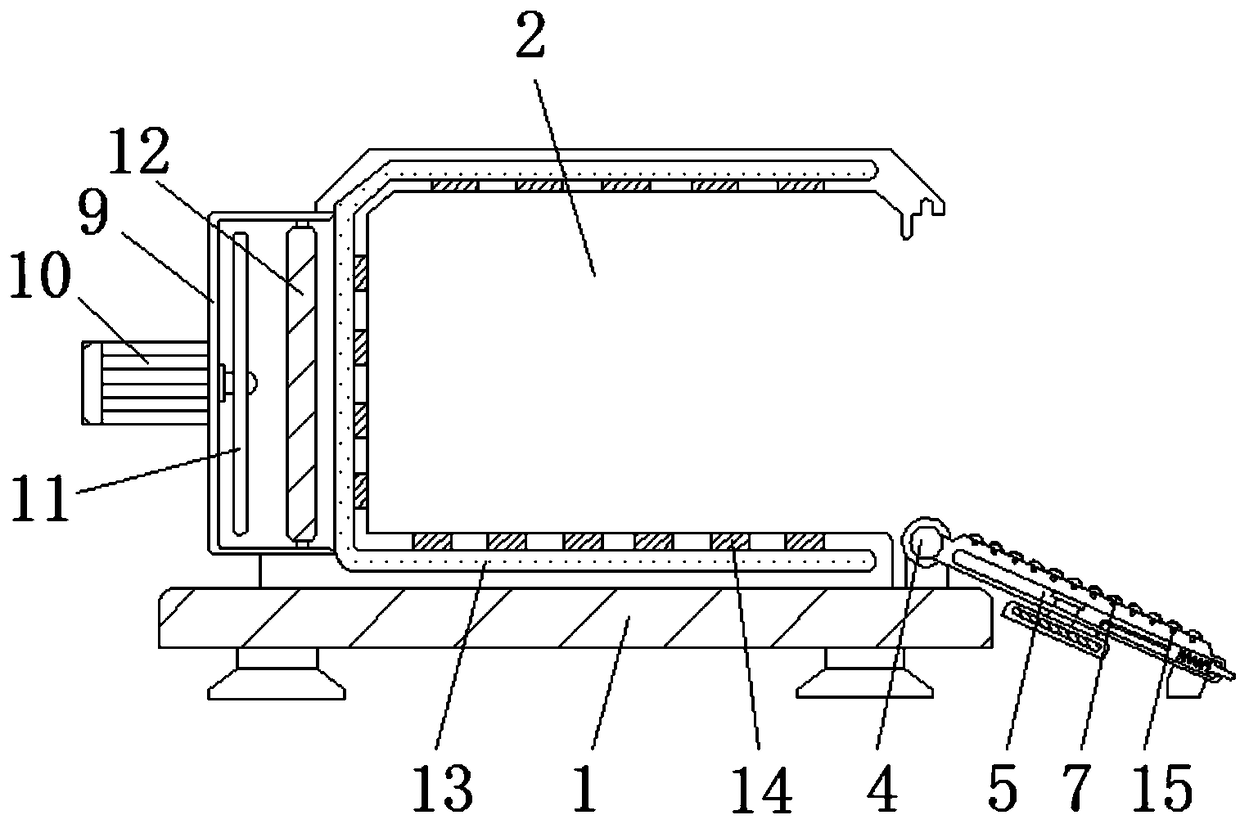

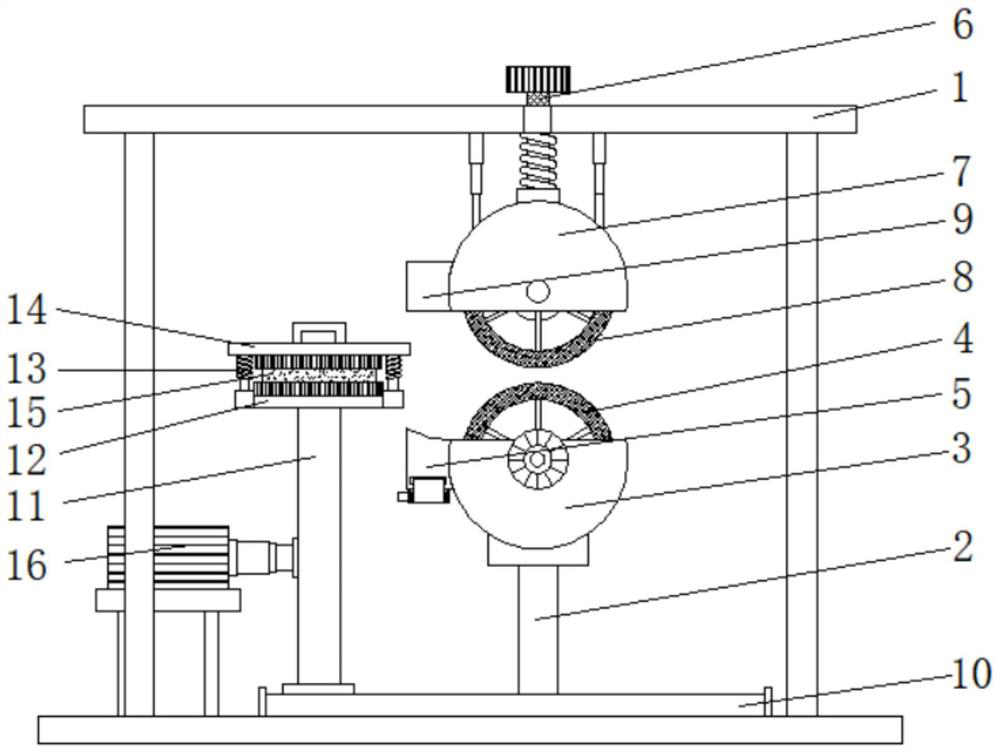

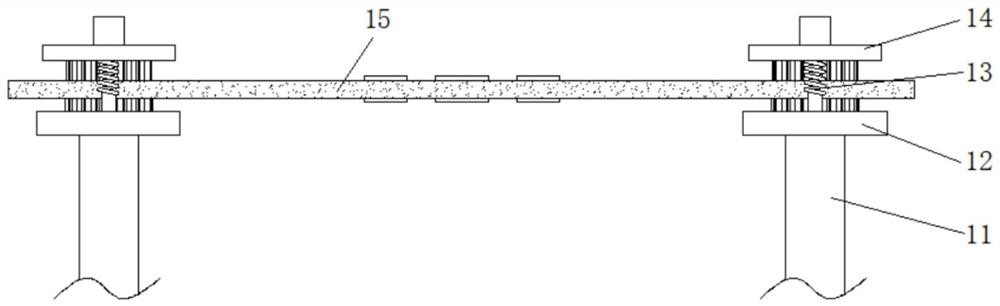

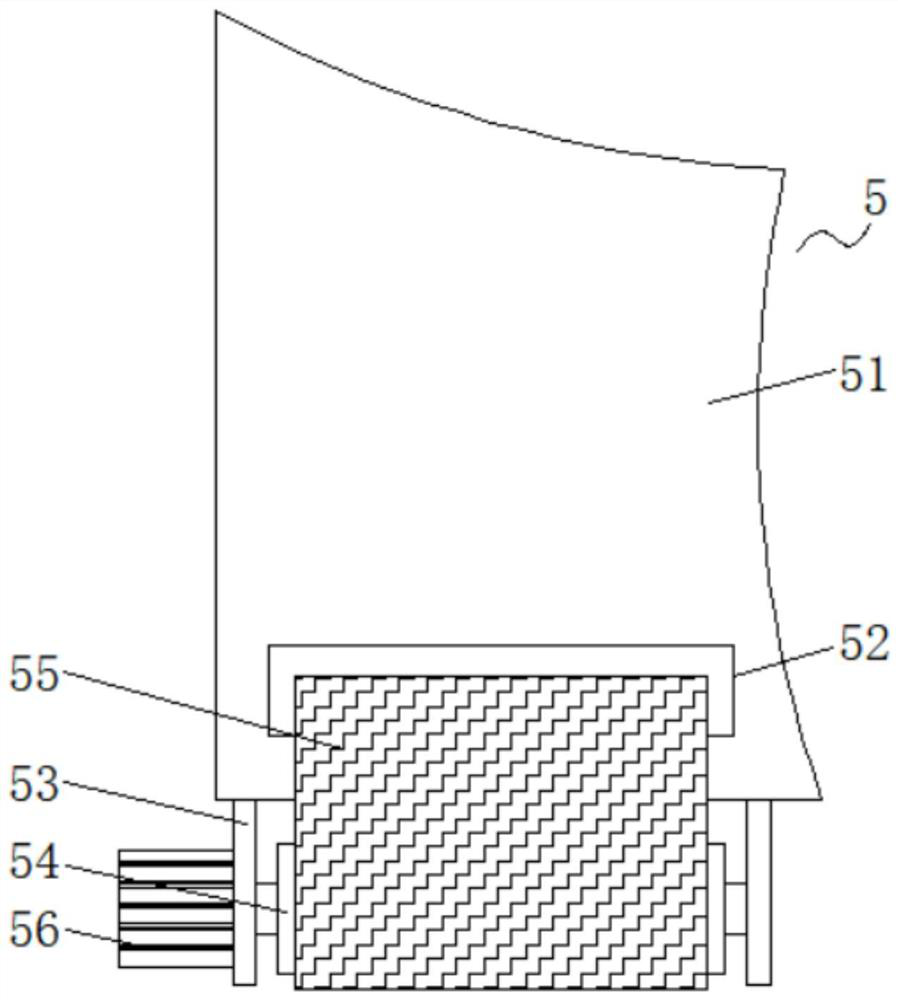

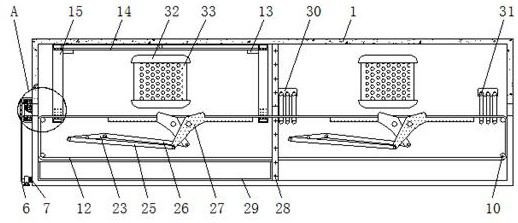

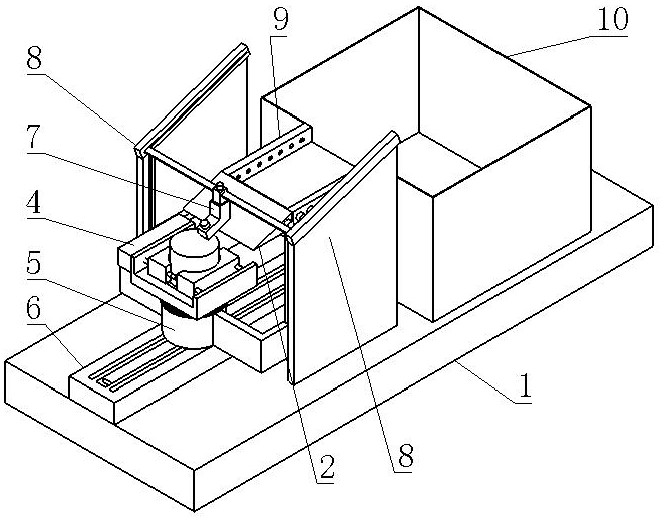

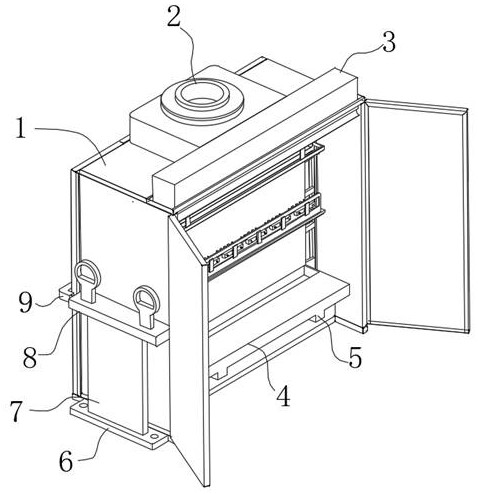

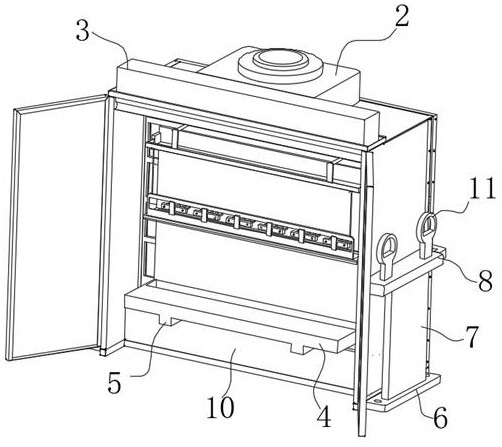

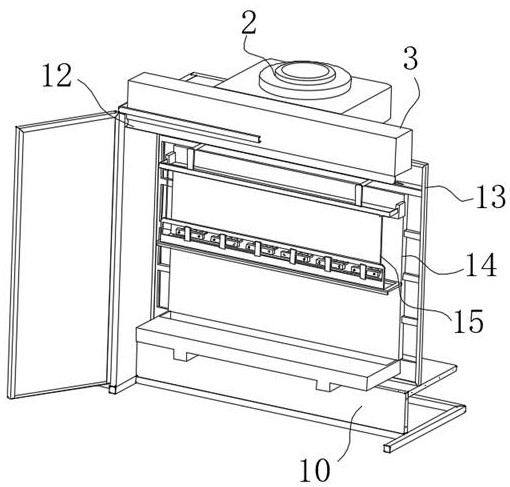

Energy-saving environmentally-friendly type paint spraying device for machining furniture

InactiveCN109482409AEffective absorptionPromote environmental protectionPretreated surfacesCoatingsEngineeringMachining

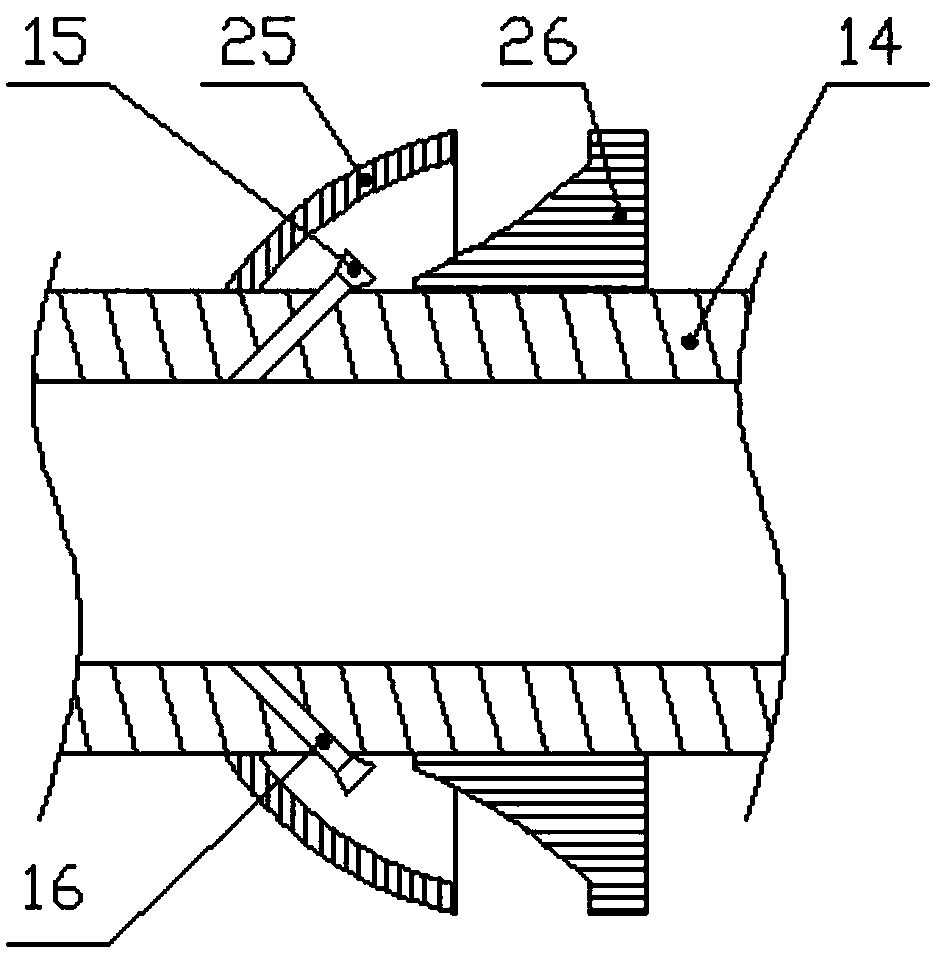

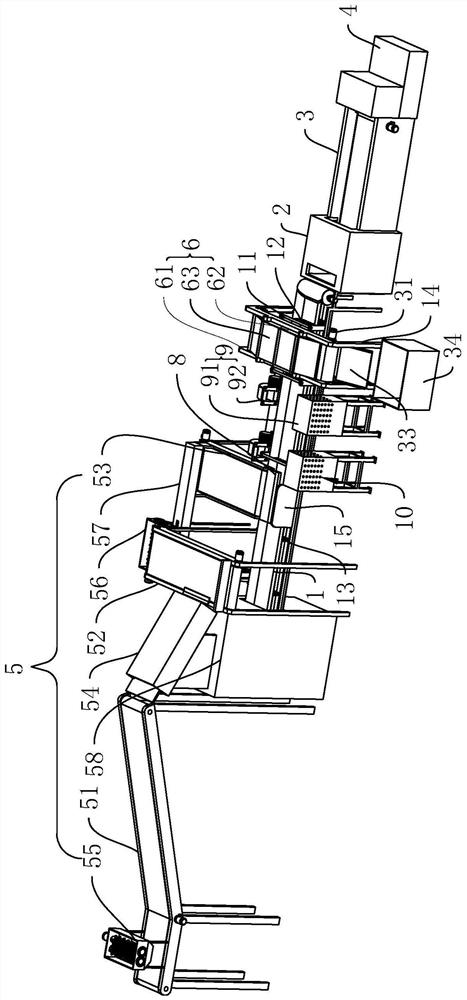

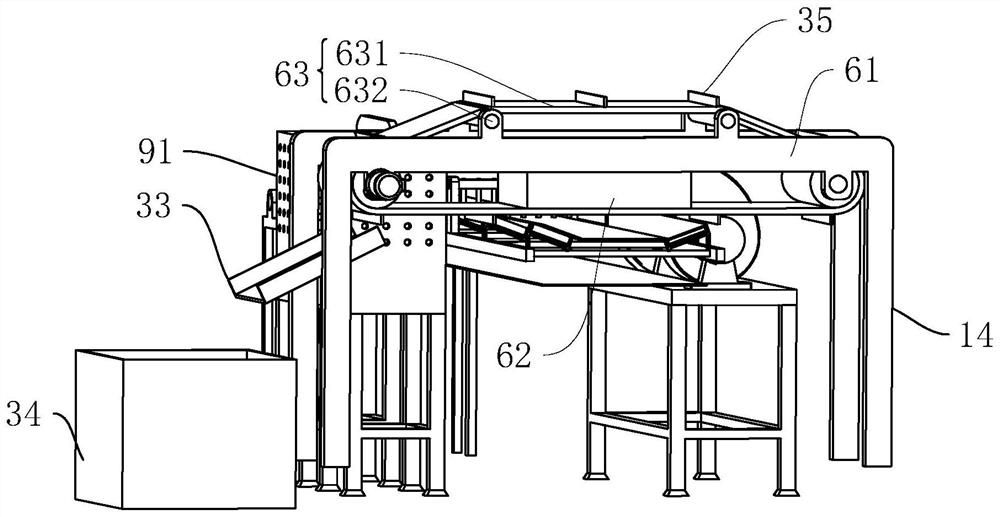

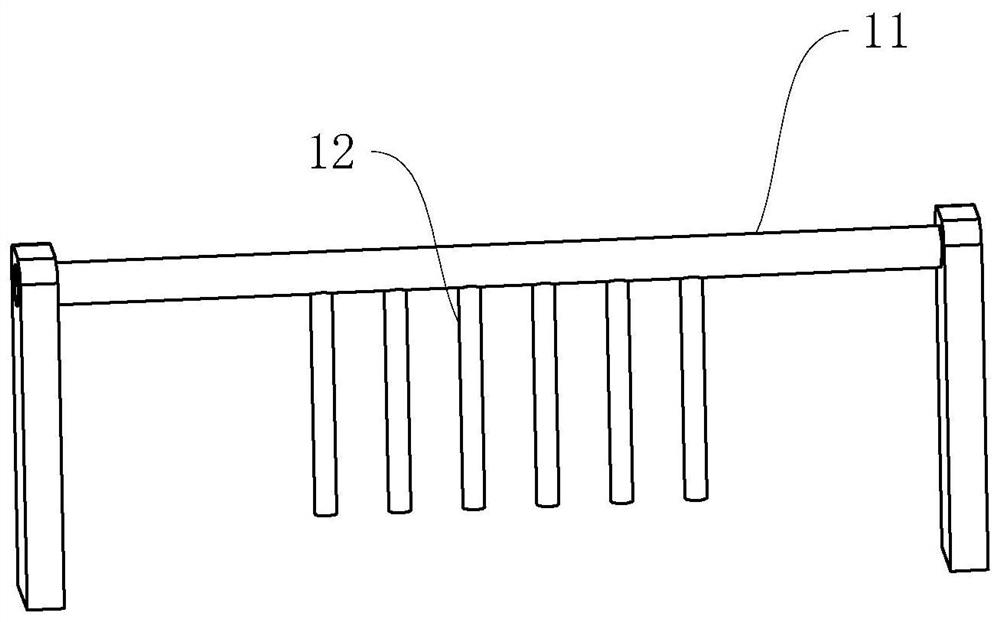

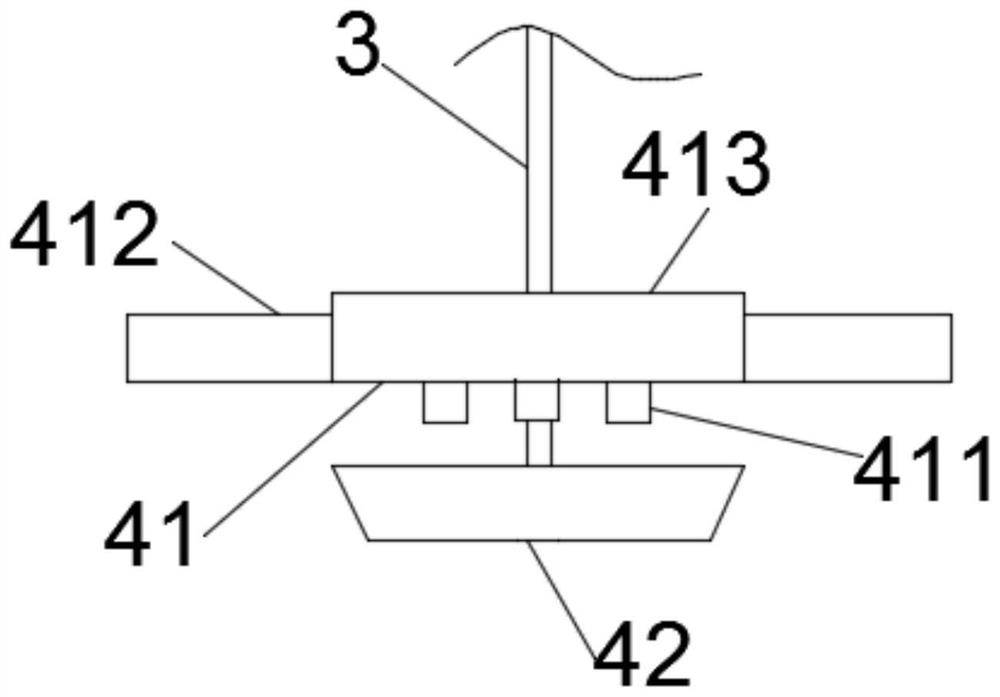

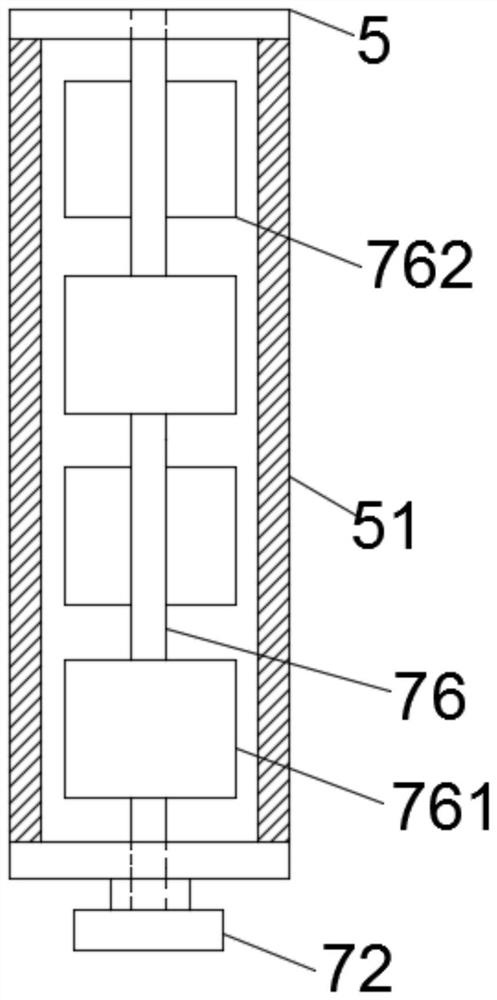

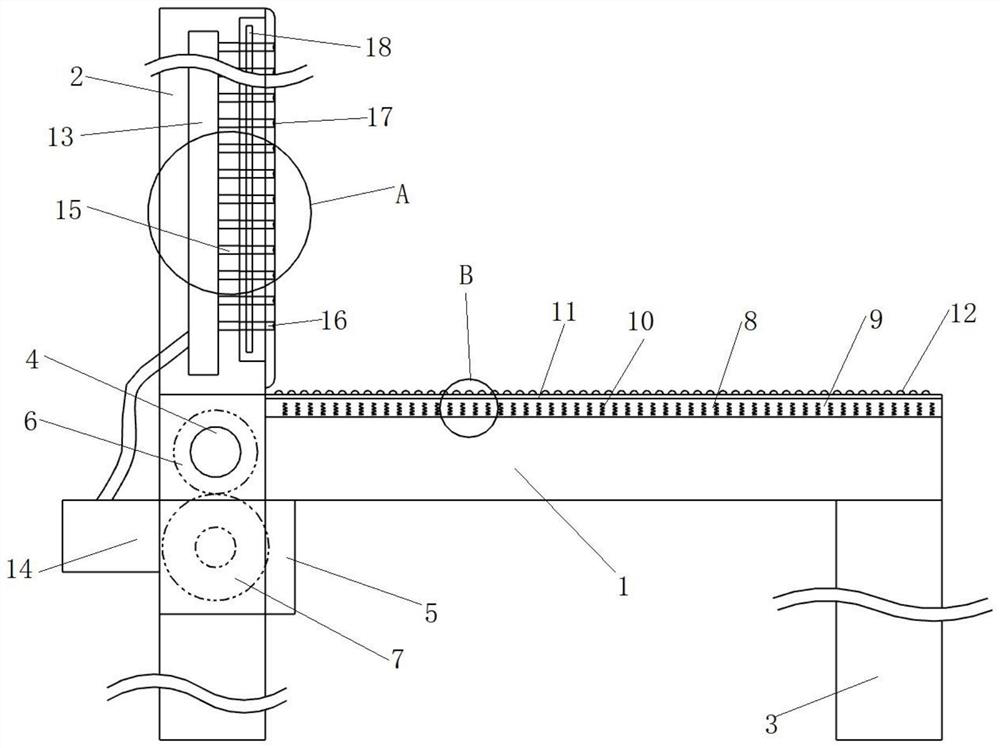

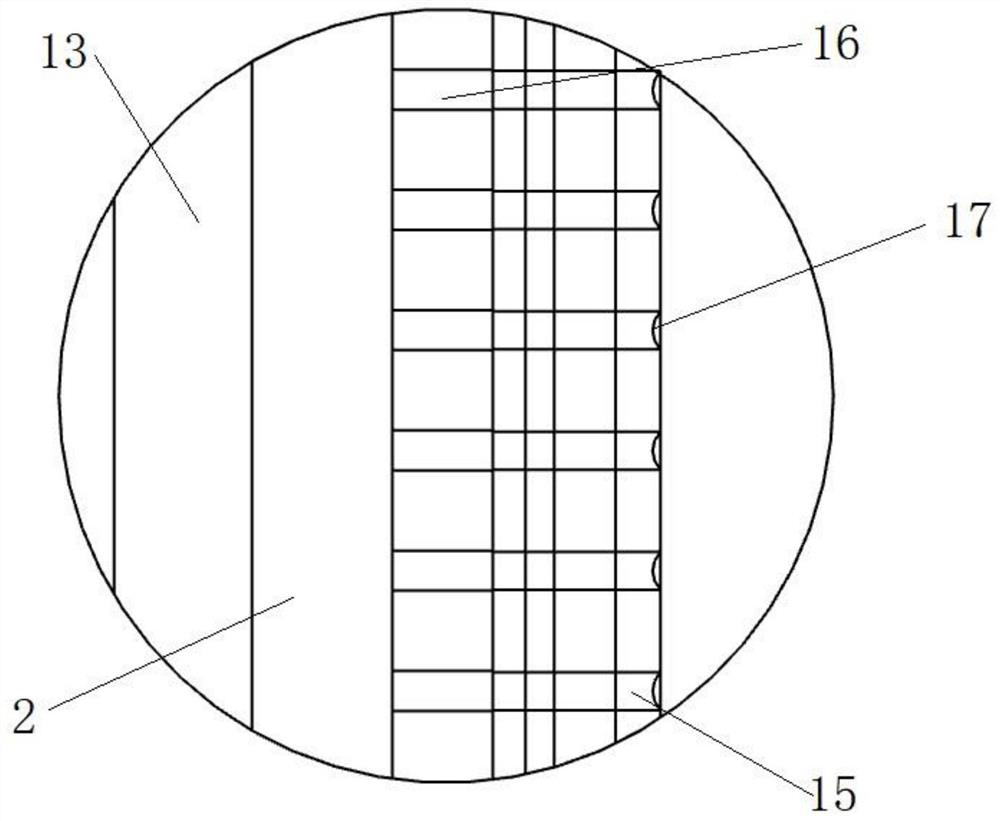

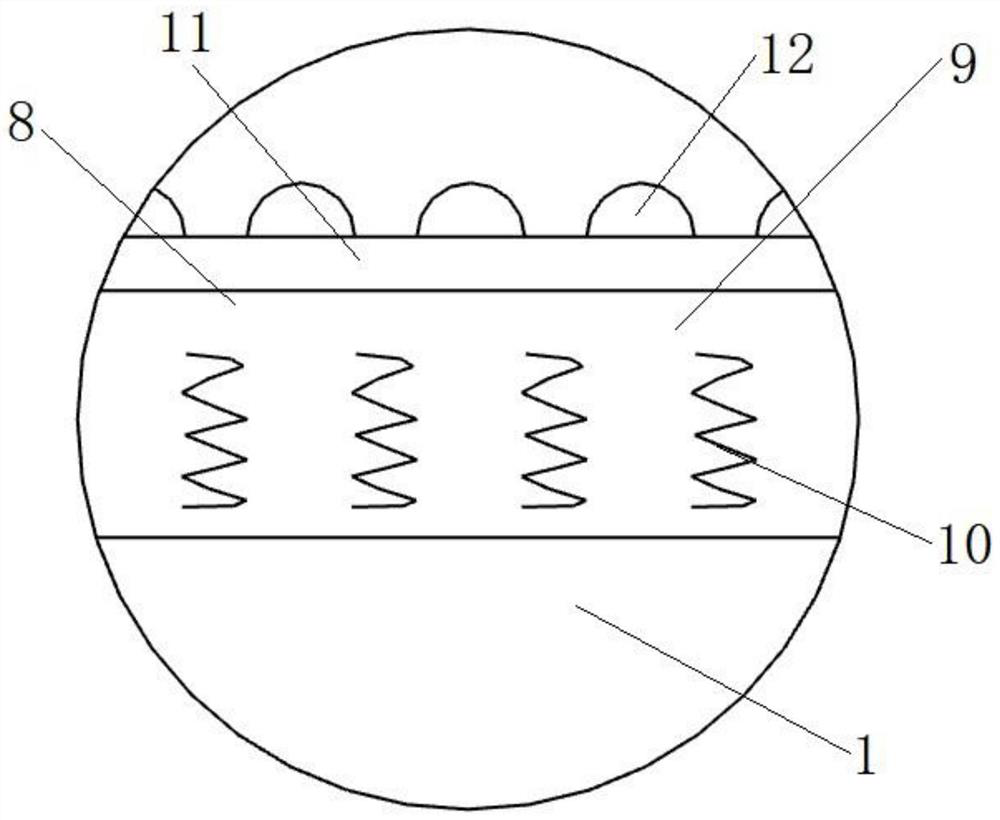

The invention belongs to the technical field of furniture machining equipment and particularly relates to an energy-saving environmentally-friendly type paint spraying device for machining furniture.The energy-saving environmentally-friendly type paint spraying device for machining furniture comprises a base. Two vertical plates are fixedly connected to the upper end of the base. A gas collectionmechanism is arranged between the two vertical plates. The left end and the right end of the gas collection mechanism are fixedly connected with side walls of the two vertical plates respectively. Agas suction mechanism is arranged at a gas collection end of the gas collection mechanism in a communicating manner. An absorption mechanism is fixedly connected to the upper end of the gas collectionmechanism. The absorption mechanism and the gas suction mechanism are arranged in a communicating manner. A heating mechanism is fixedly connected to a side wall of the right-side vertical plate. Theheating mechanism and a gas output end of the absorption mechanism are arranged in a communicating manner. A transparent glass paint spraying groove is formed between the two vertical plates. The paint spraying groove is located under the gas collection mechanism. Side walls of both the left end and the right end of the paint spraying groove are fixedly connected with side walls of the two vertical plates respectively. A hollow-out plate is fixedly installed in the paint spraying groove. The energy-saving environmentally-friendly type paint spraying device for machining furniture has the advantages that a pungent smell produced by paint spraying can be effectively absorbed; and in addition, drying can also be conducted on furniture painted.

Owner:杭州知桔科技有限公司

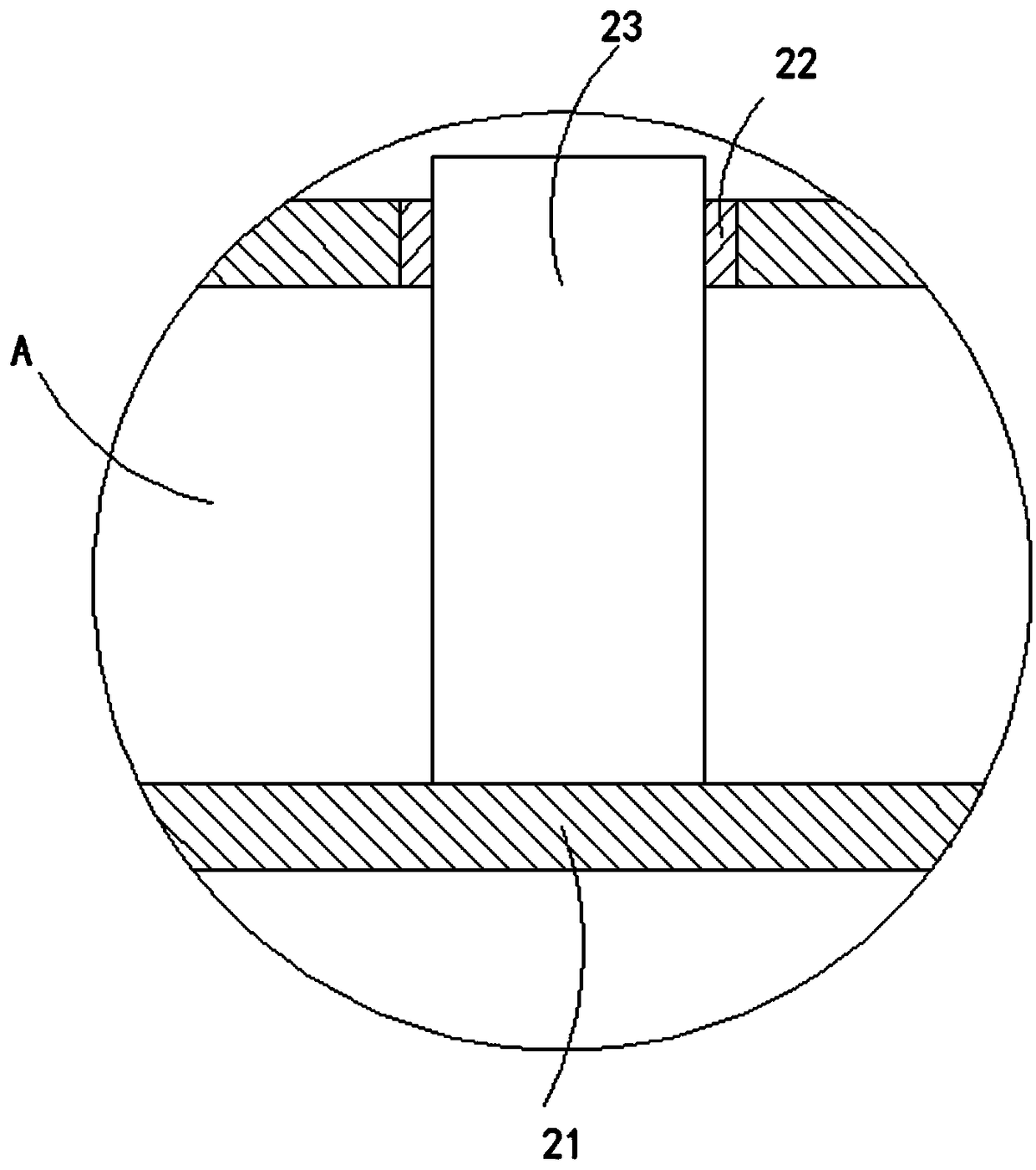

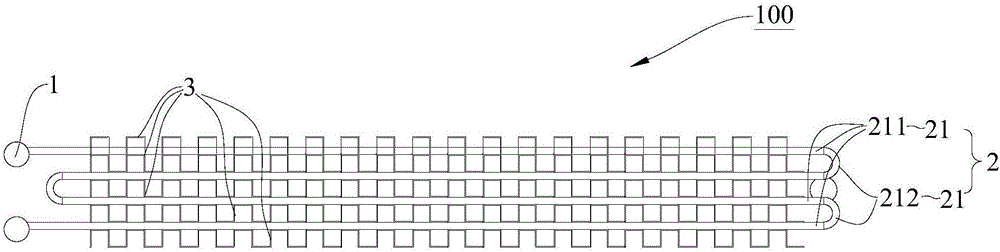

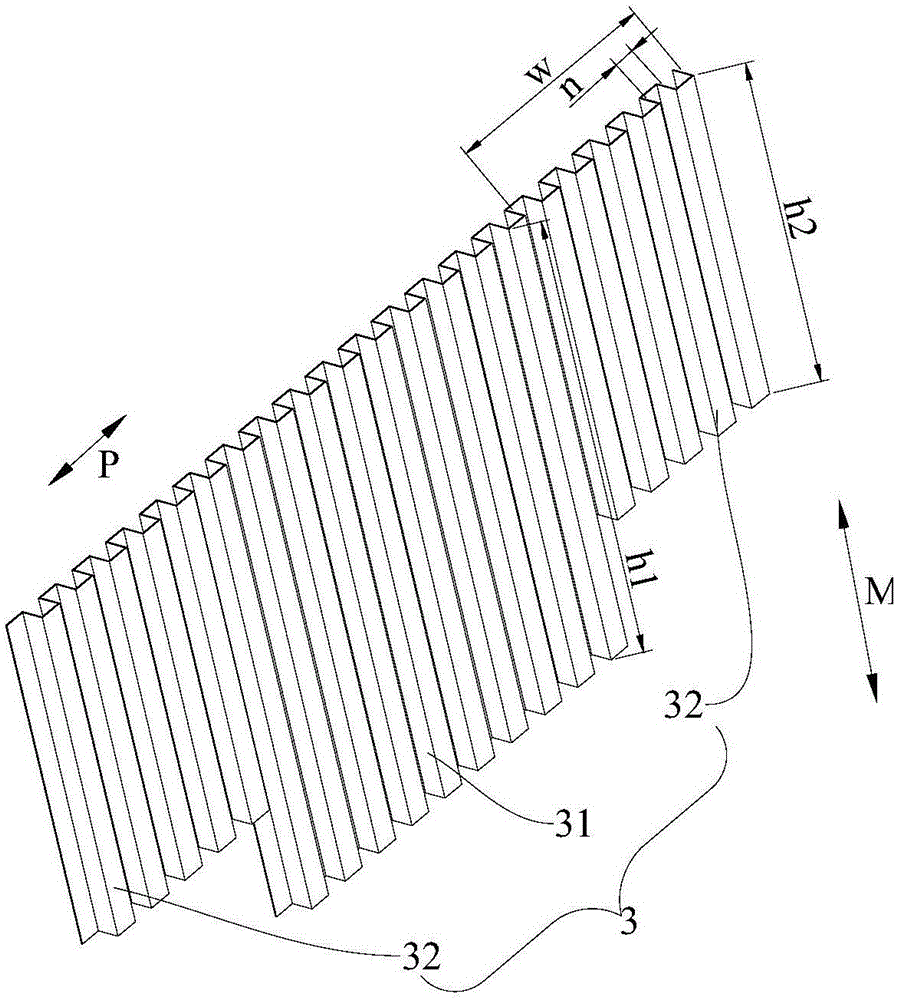

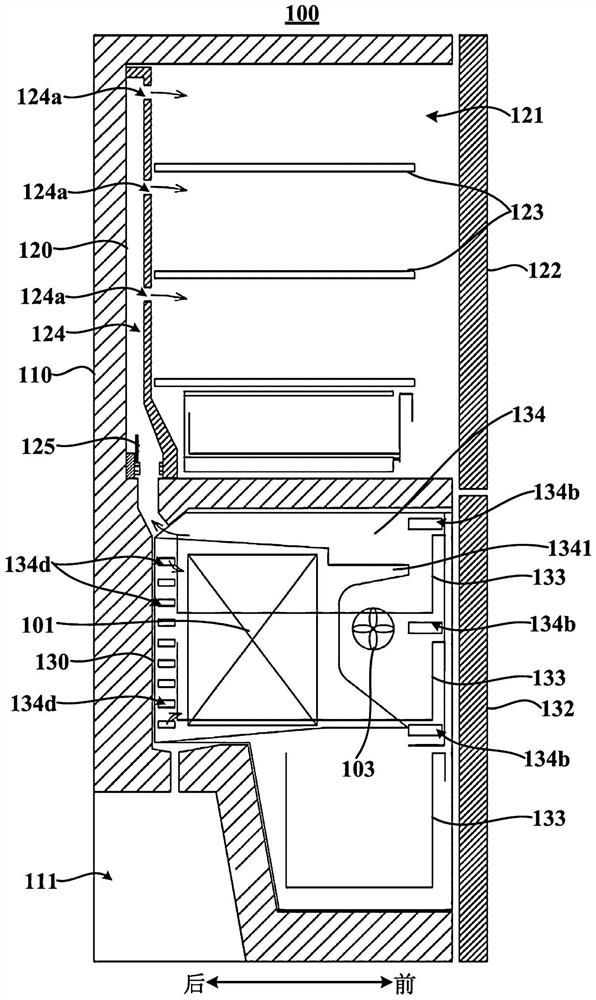

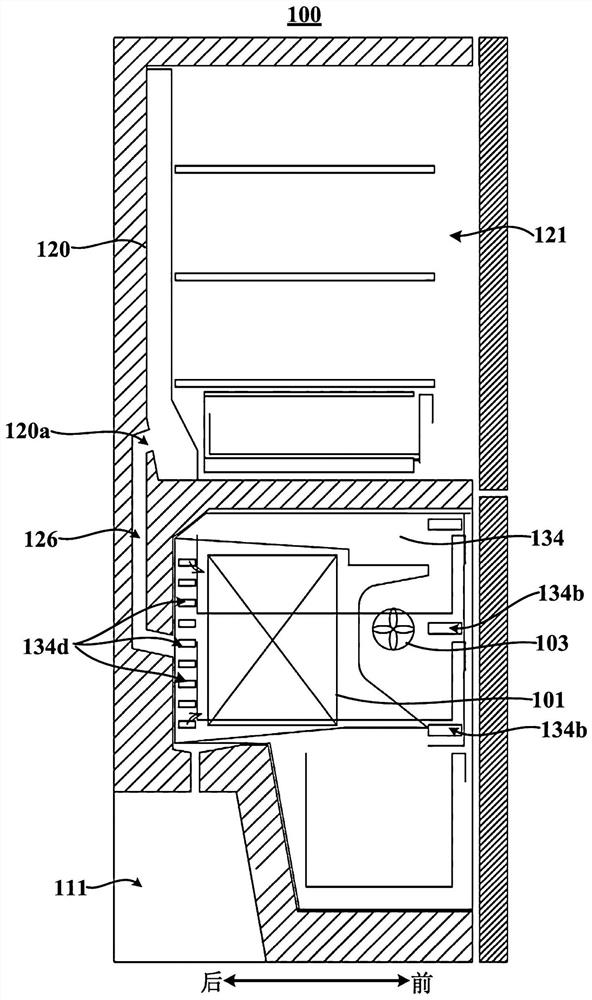

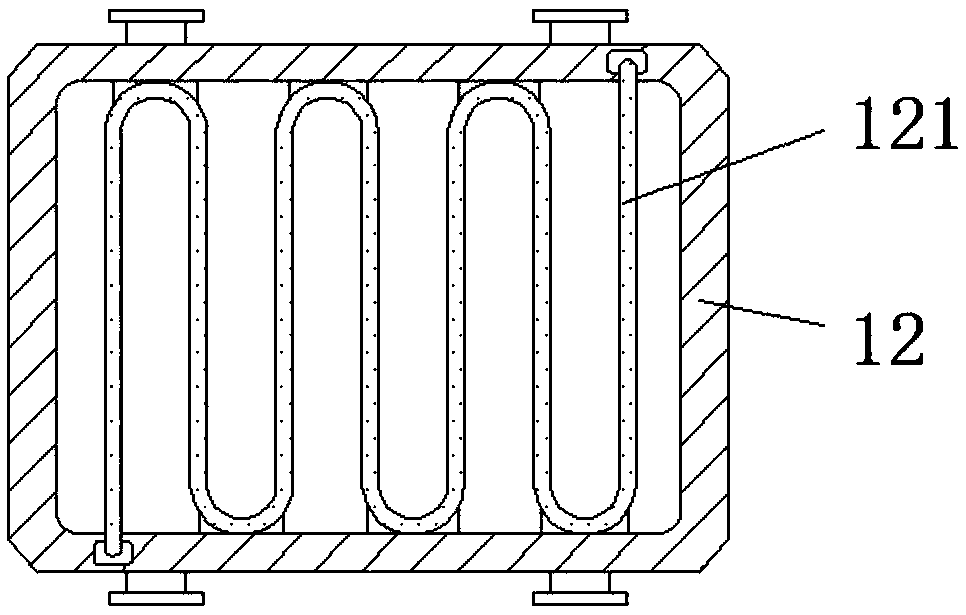

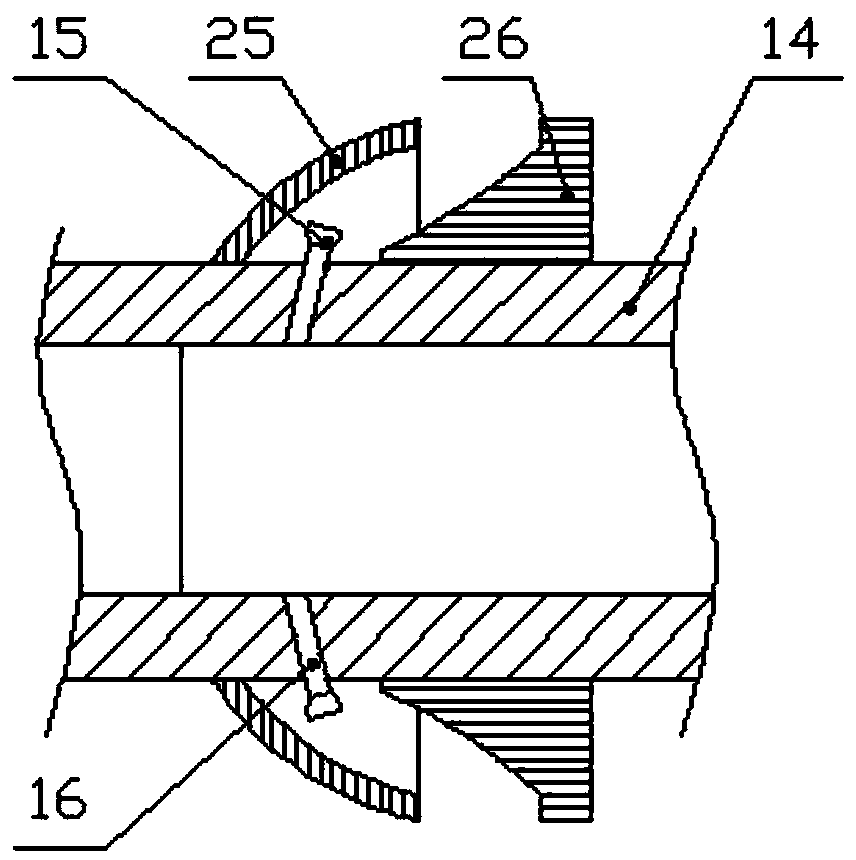

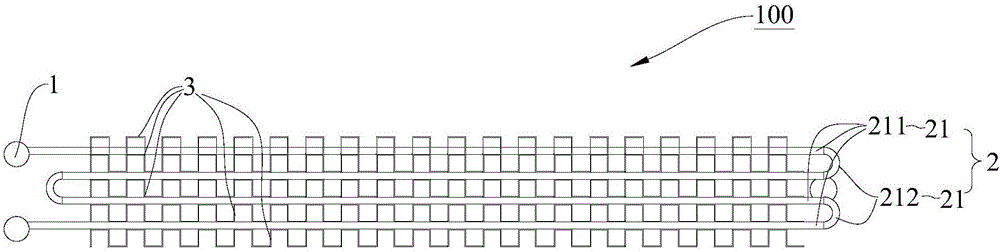

Microchannel heat exchanger, refrigerator and air-cooled refrigerator

InactiveCN106288525ALittle impact on performanceIncrease distribution spaceDomestic refrigeratorsEvaporators/condensersEngineeringRefrigerant

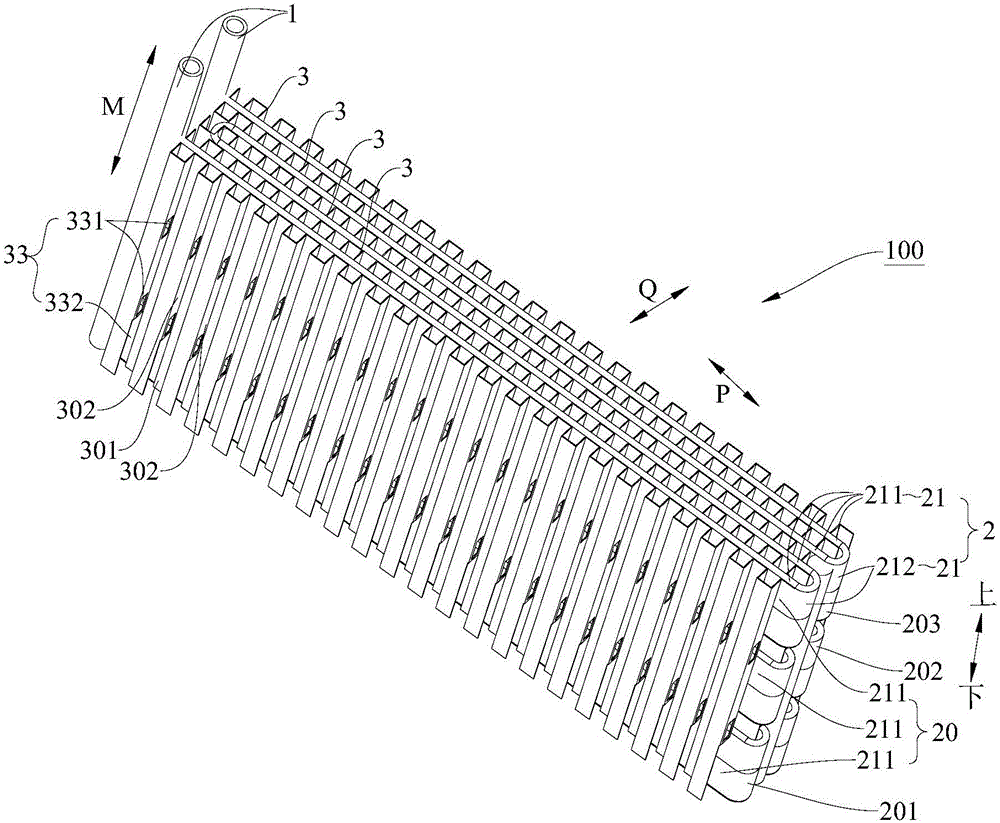

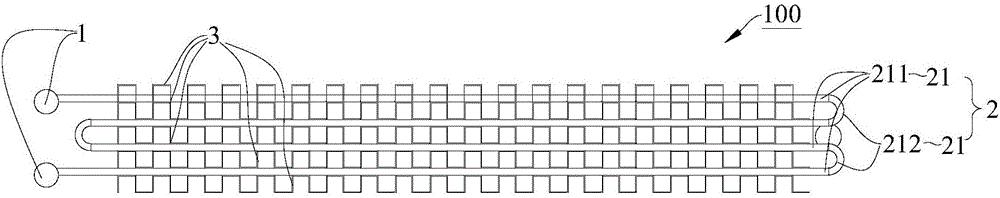

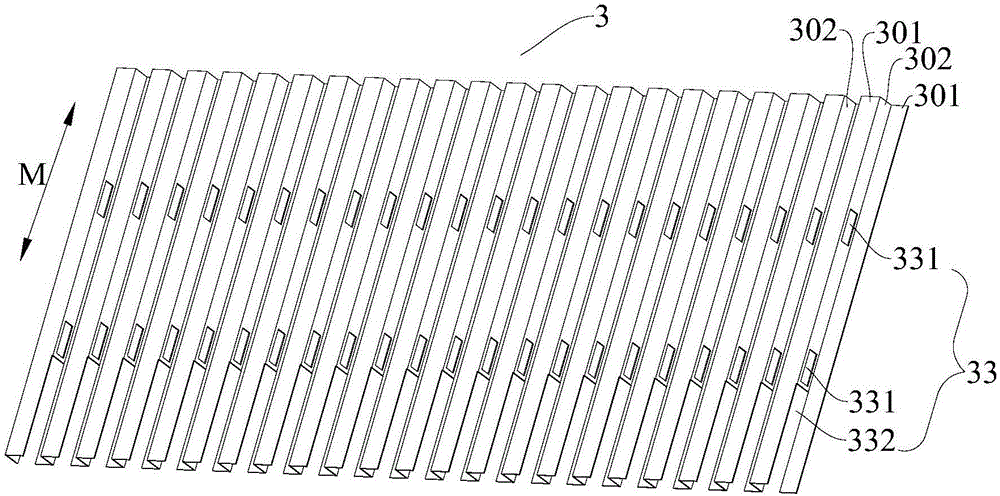

The invention discloses a microchannel heat exchanger, a refrigerator and an air-cooled refrigerator. The microchannel heat exchanger comprises two headers, a plurality of heat exchange tubes and fins, and the two headers are arranged in parallel. Both ends of each of the heat exchange tubes are respectively connected with the two headers, the heat exchange tubes are bent into a plurality of tube layers along the length direction, and the area of passage of part of the heat exchange tubes is larger than the area of passage of the rest of the heat exchange tubes. Each fin is arranged between two adjacent tube layers or on the outside of the outermost tube layer, each fin extends in a corrugated form along the extension direction of the heat exchange tubes, and each fin continuously extends along the extension direction of the headers. The microchannel heat exchanger according to the invention solves the problem that water cannot be drained out because the amount of the water hung on the surfaces of fins is large, and thereby stubborn ice can be prevented from being produced on the surfaces to affect the efficiency of heat exchange. By differentially designing the areas of passage of the heat exchange tubes, the heat exchange tubes with the large area of passage can be arranged at the first windward part of the heat exchanger, and thereby the flow of refrigerant of the heat exchange tubes becomes uniform.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

Fermentation tank being uniform in fermentation temperature and quick in cooling

The invention discloses a fermentation tank being uniform in fermentation temperature and quick in cooling. The fermentation tank comprises an outer tank body and an inner tank body, wherein the innertank body is located in the outer tank body, and is fixedly connected with the outer tank body; a copper tube is arranged between the inner tank body and the outer tank body; a heat dissipation device is fixedly connected to the lower end of the outer tank body, and comprises a heat dissipation tank and a heat dissipation fan; the heat dissipation fan is located at the bottom of the heat dissipation tank, and is fixedly connected with the heat dissipation tank; a cold grid is fixedly connected to the upper end of the heat dissipation fan; a water tank is fixedly connected to the side wall ofthe heat dissipation tank; a circulating pump is fixedly connected to one side of the water tank, and communicates with the water tank; the cold grid communicates with the water tank through a water pipe; and one end of the copper tube communicates with the cold grid, and the other end of the copper tube communicates with the circulating pump. According to the fermentation tank being uniform in fermentation and quick in cooling disclosed by the invention, the heat dissipation device is arranged, so that quick cooling treatment can be efficiently performed on the fermentation tank by the heat dissipation device in a high-efficiency manner, so that the using of the fermentation tank is convenient, and the service life of the fermentation tank is prolonged.

Owner:江西省食品发酵研究所

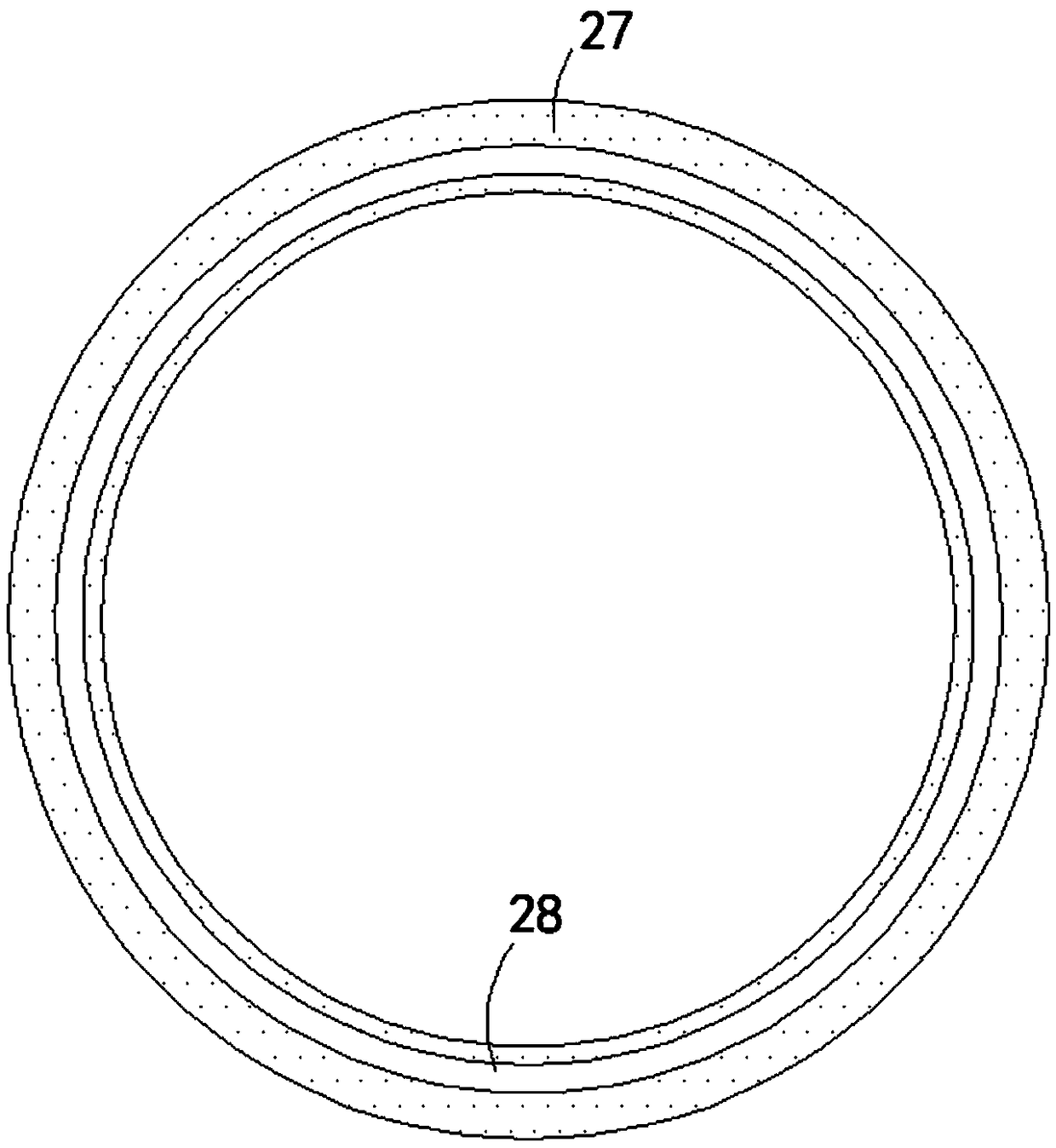

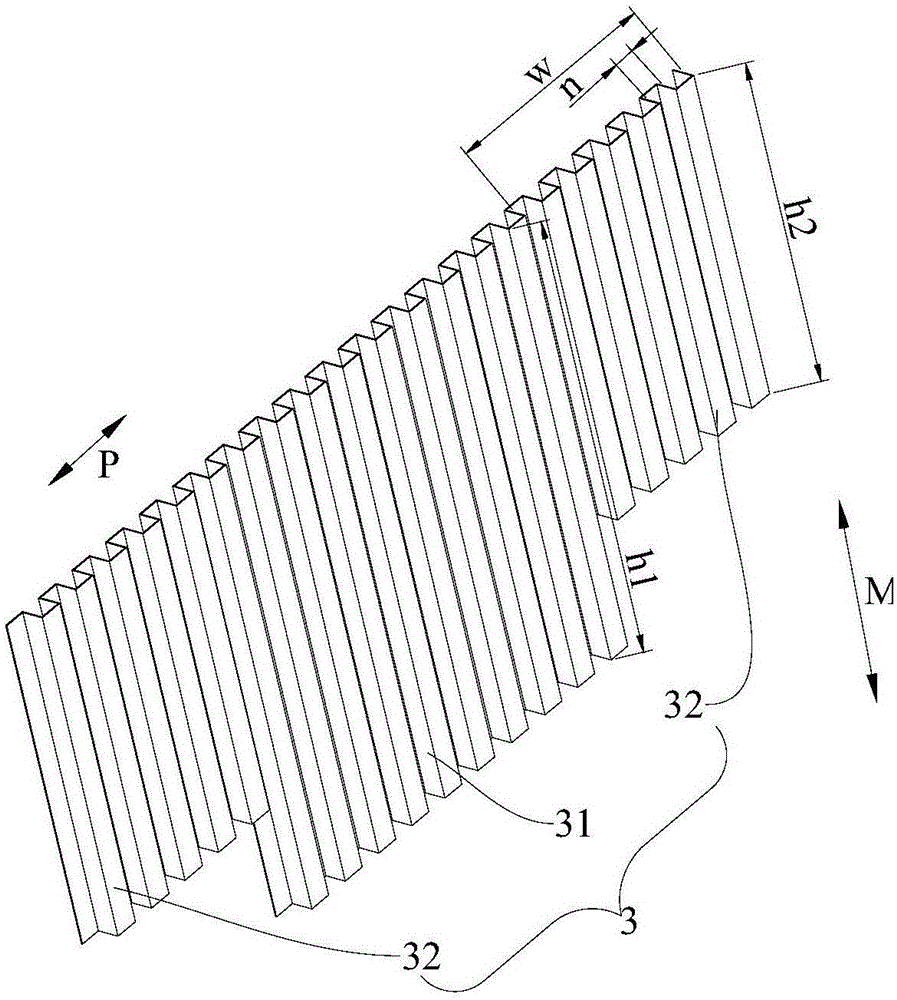

Micro-channel heat exchanger, refrigerator and air-cooled refrigerator

InactiveCN106288526AImprove heat transfer effectSolve the large amount of hanging waterDomestic refrigeratorsEvaporators/condensersPlate heat exchangerEngineering

The invention discloses a micro-channel heat exchanger, a refrigerator and an air-cooled refrigerator. The micro-channel heat exchanger comprises two collecting pipes, a plurality of heat exchange tubes and fins, wherein the two collecting pipes are arranged in parallel. Two ends of the plurality of heat exchange tubes are connected to the two collecting pipes, respectively, the plurality of heat exchange tubes are bent along the length direction to form a plurality of pipe layers, and the open area of part of the heat exchange tubes are greater than that of the rest heat exchange tubes. Each of the fins is arranged between adjacent two pipe layers or on the outer side of the pipe layer in the outermost layer, each of the fins extends in a corrugated shape in the extension direction of each of the heat exchange tubes, each of the fins extends continuously in the extension direction of each of the collecting pipes, and ventilating holes are formed in each of the fins. The micro-channel heat exchanger disclosed by the invention solves the problems that the water hanging amount on the surfaces of the fins is relatively great and water cannot be thoroughly discharged, and the condition that obstinate ice is generated on the surface of the micro-channel heat exchanger to affect the heat exchange efficiency is avoided. In addition, the defrosting period can be prolonged, the refrigerant flows of the plurality of heat exchange tubes are uniform, and the heat exchange property is enhanced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

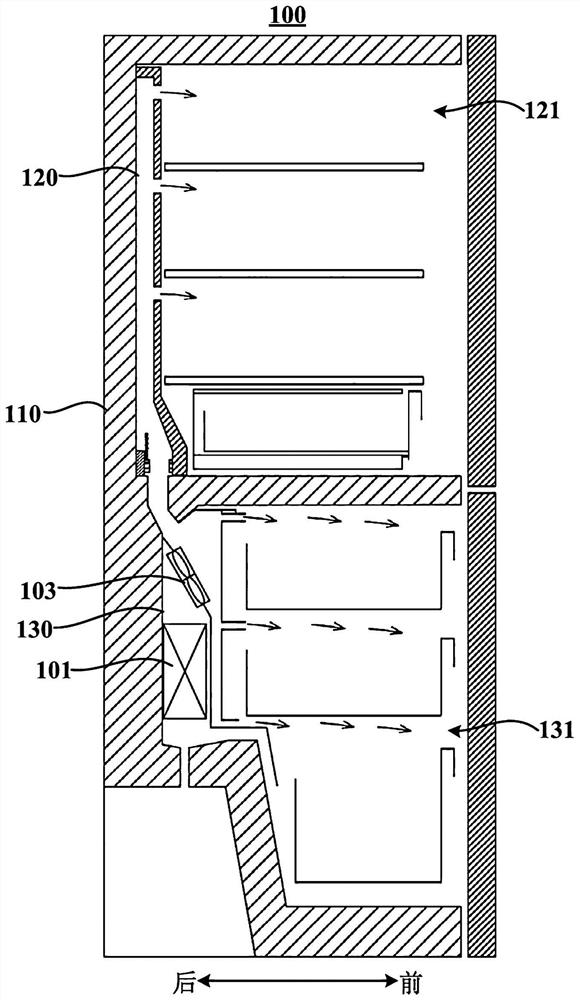

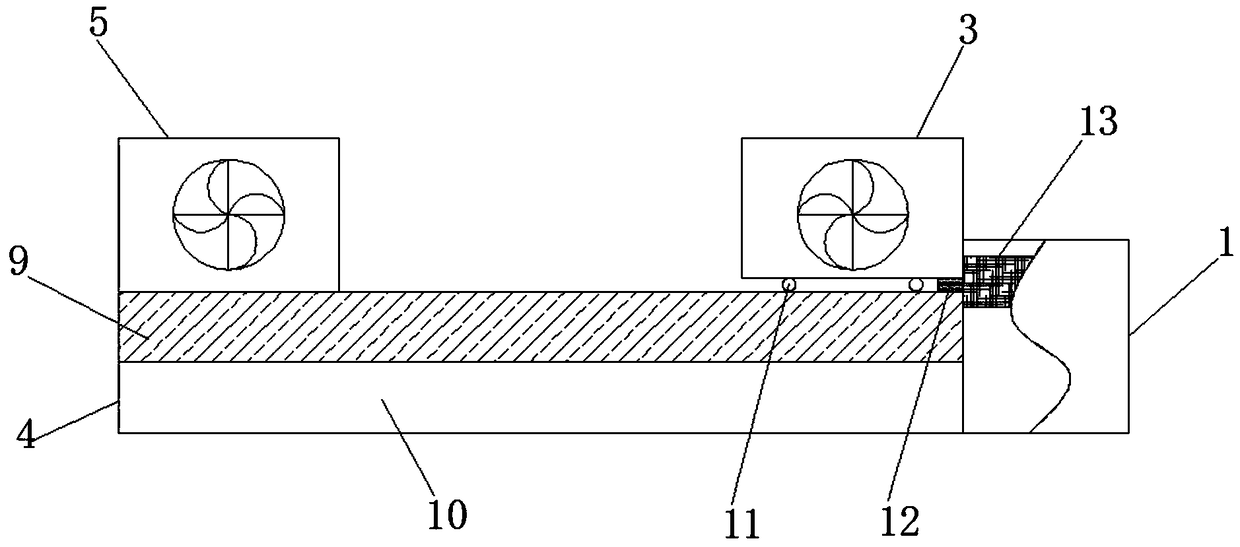

Refrigerator with air supply fan located in front of evaporator

PendingCN111609616AIncrease the depth sizeReduce the temperature difference before and afterLighting and heating apparatusDomestic refrigeratorsThermodynamicsIcebox

The invention provides a refrigerator with an air supply fan located in front of an evaporator. The refrigerator comprises a storage inner container and the evaporator. At least one storage chamber islimited in the storage inner container. An air flue chamber is defined by one side walls in the transverse direction of the storage chambers, and the evaporator and the air supply fan are arranged inthe air flue chamber. The air supply fan is located in front of the evaporator and is configured to prompt at least part of airflow cooled by the evaporator to flow through the air flue chamber to flow into at least one storage chamber. Thus, space which is originally ineffective is fully utilized, and the depth size of the storage chambers is increased.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Automobile plate component injection mold cooling device

The invention discloses an automobile plate component injection mold cooling device which comprises a base, a cooling chamber and a motor. A cooling tank is fixed to the upper side of the base, a clamp groove is formed in the right side of the cooling tank, the base is connected with a door by a rotary shaft, a fixture block is arranged on the upper side of the door and is connected with a fixingblock by a spring, the fixing block is fixedly mounted inside the door, a condensation plate is fixed into the cooling chamber, air outlet holes are formed in the inner surface of the cooling tank, and a connecting rope is connected with the lower side of the fixture block. The automobile plate component injection mold cooling device has the advantages that the automobile plate component injectionmold cooling device is provided with a wind guide plate and the condensation plate, accordingly, cold air generated by a condensation tube inside the condensation plate can be conveniently flown intothe wind guide plate via a fan, further can be conveniently exhausted into the air outlet holes in the inner surface of the cooling tank via wind guide holes in the surfaces of a plate inside the wind guide plate and wind guide holes in the surfaces of wind guide tubes and further can be conveniently exhausted into the cooling tank, and cooling effects of the automobile plate component injectionmold cooling device can be improved.

Owner:陈莉莉

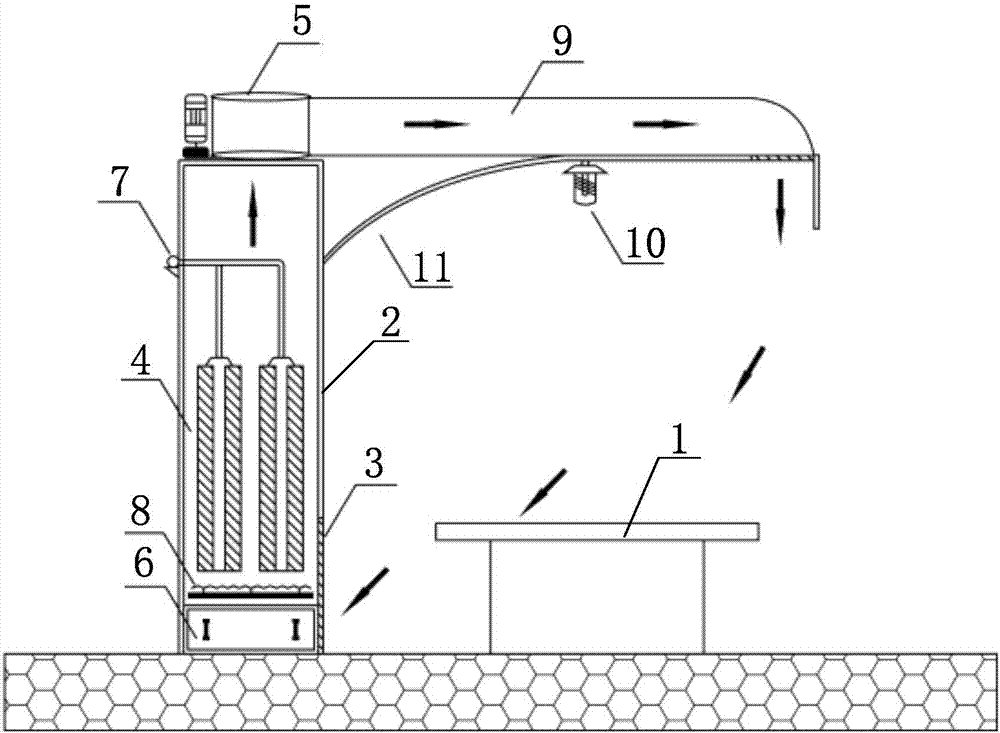

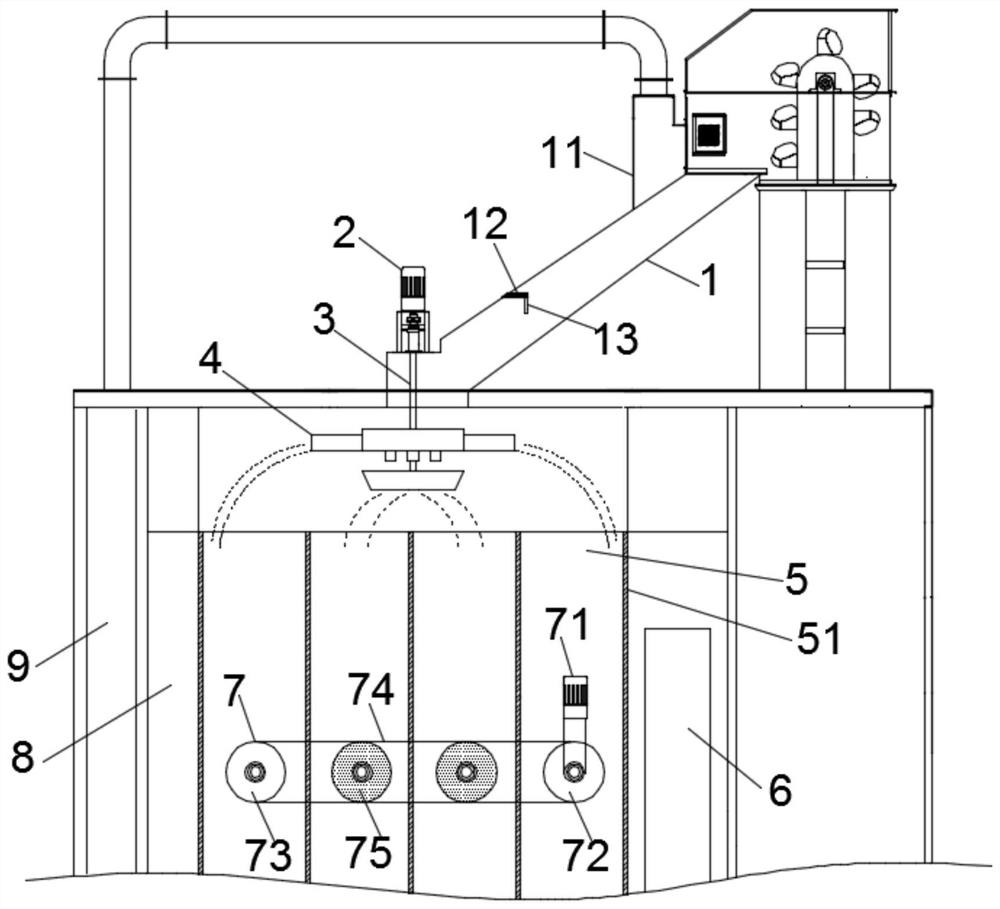

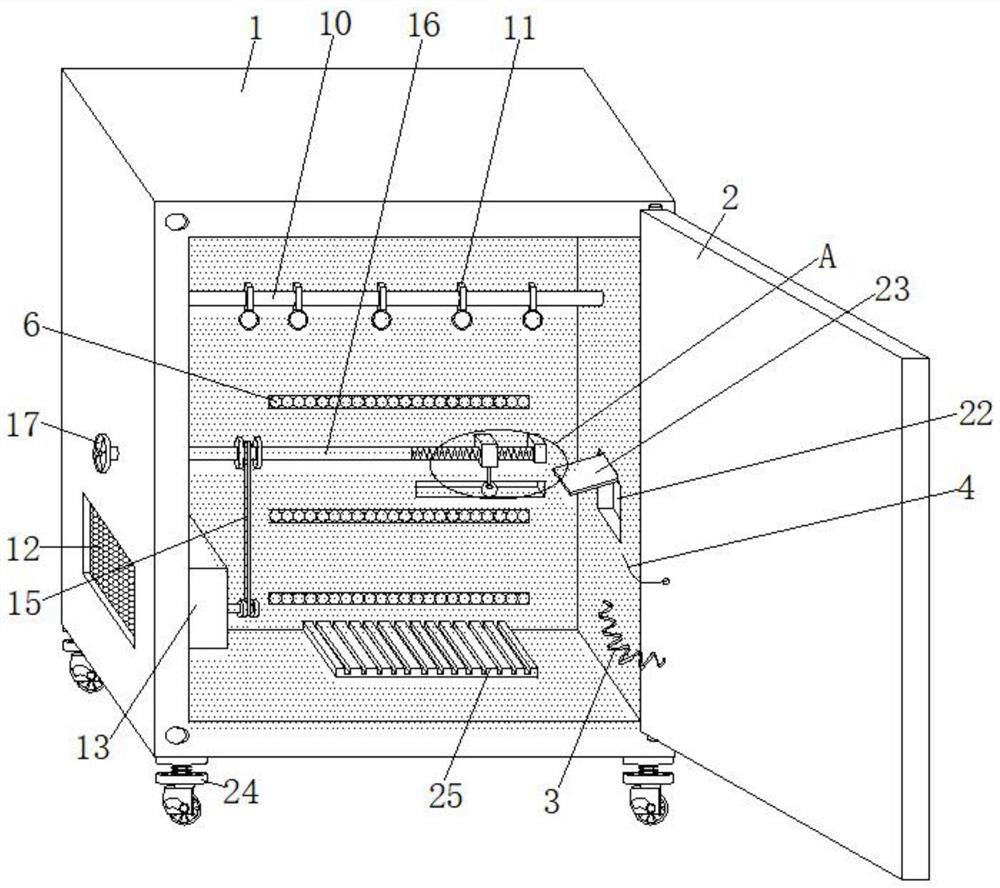

Grinding room with recycling function

InactiveCN107350972AFeel cool to workDamage to healthDispersed particle filtrationGrinding/polishing safety devicesAir pollutionSurface grinding

The invention discloses a grinding room with a recycling function. The grinding room comprises a grinding platform. A dust suction recycling pipe is arranged beside the grinding platform. A dust suction opening is formed in the side face, close to the grinding platform, of the dust suction recycling pipe. A cloth bag filtering device is arranged in the dust suction recycling pipe. A pulse air pipe is connected to the top of the cloth bag filtering device. An outlet of the dust suction recycling pipe is connected with a suction opening of an exhaust fan. An air outlet of the exhaust fan is connected with an air return pipeline. The air return pipeline is horizontally arranged and provided with an air outlet. A dust storage bin is arranged below the cloth bag filtering device. By the adoption of the grinding room, large-concentration dust generated during the surface grinding operation and deep machining of components can be sucked away and collected in a concentrated manner, air is recycled, the air is exhausted indoors after the dust is removed, the purified air is recycled to the grinding room, workers do not need to wear masks when working in the grinding room, the problem of the emission pollution existing in traditional grinding can be solved, and the air pollution and the harm to the body health of the workers are avoided.

Owner:成都漆彩之星环保科技有限公司

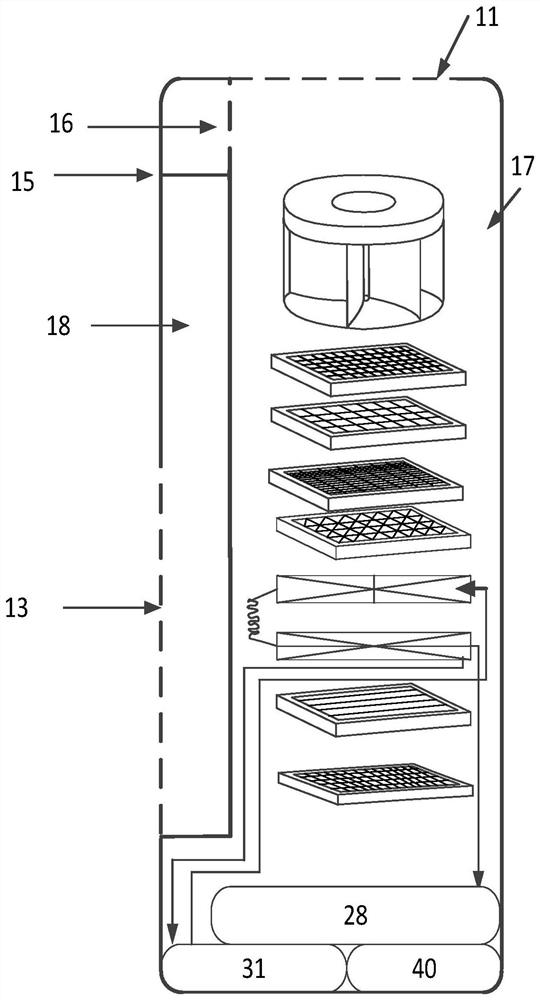

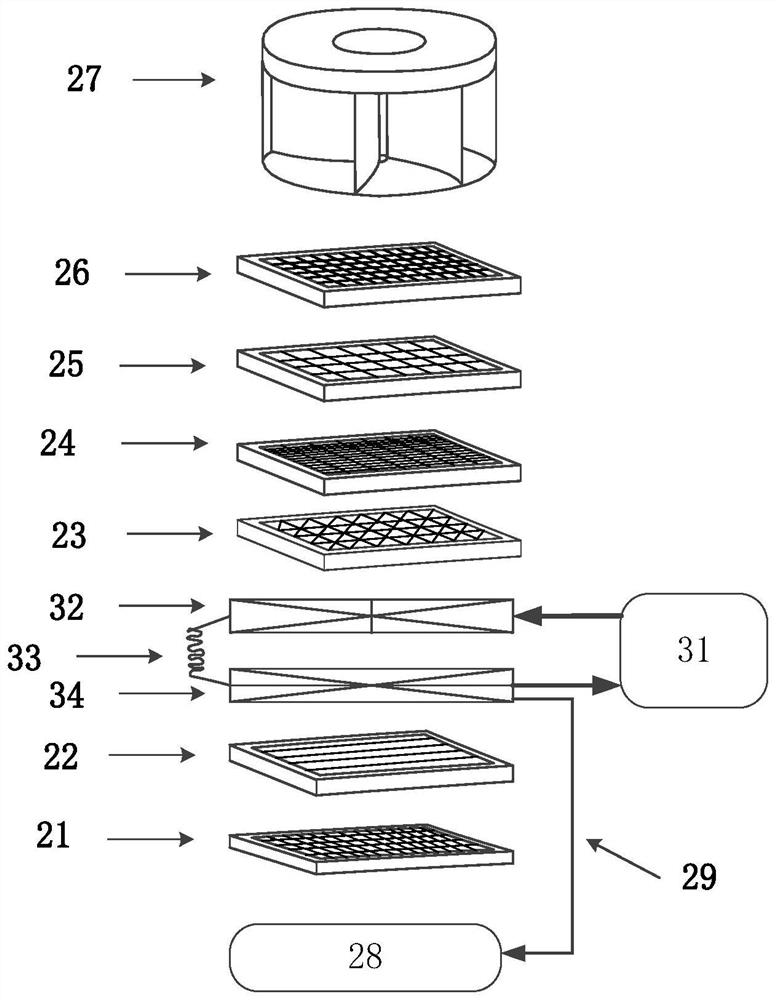

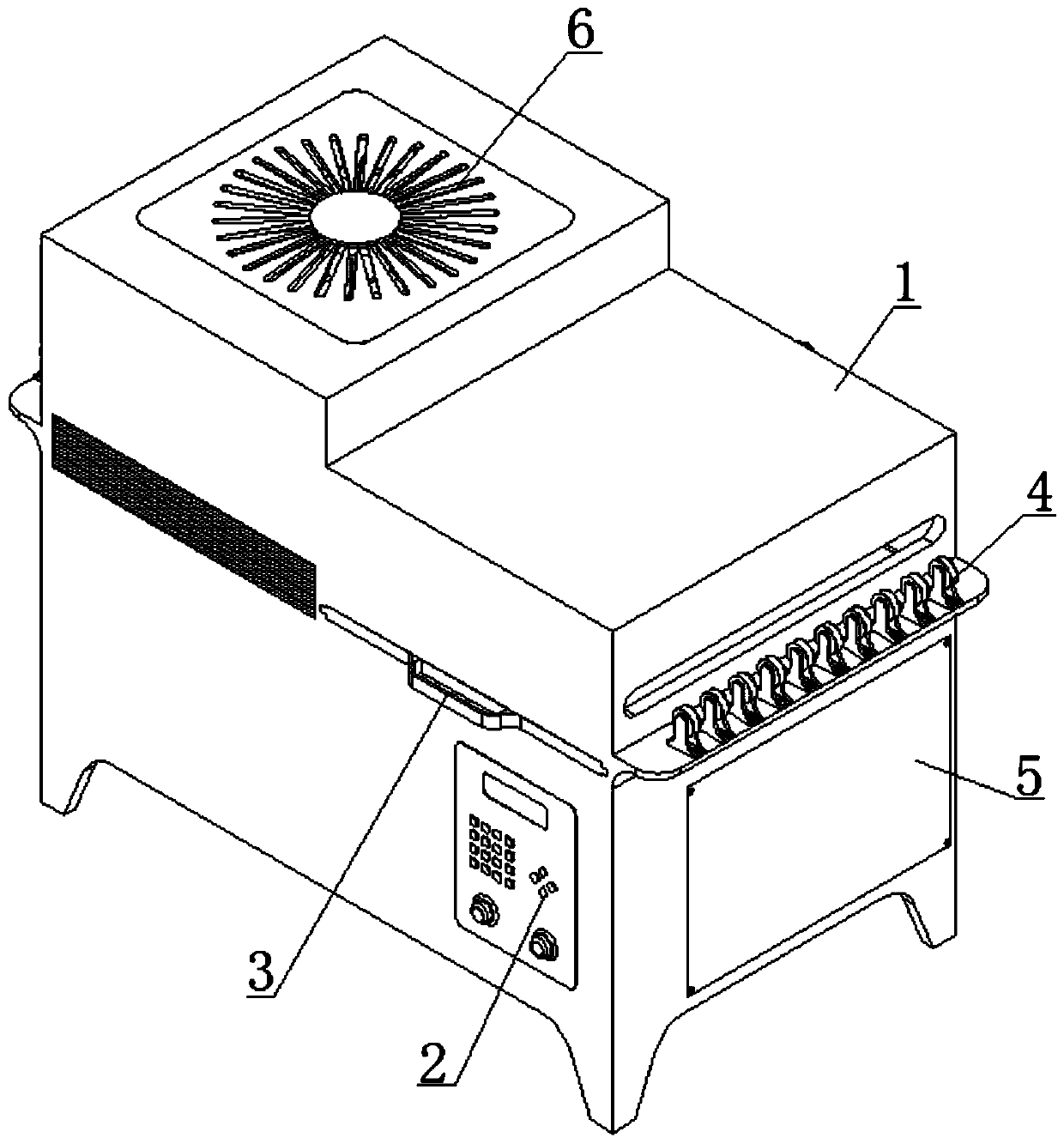

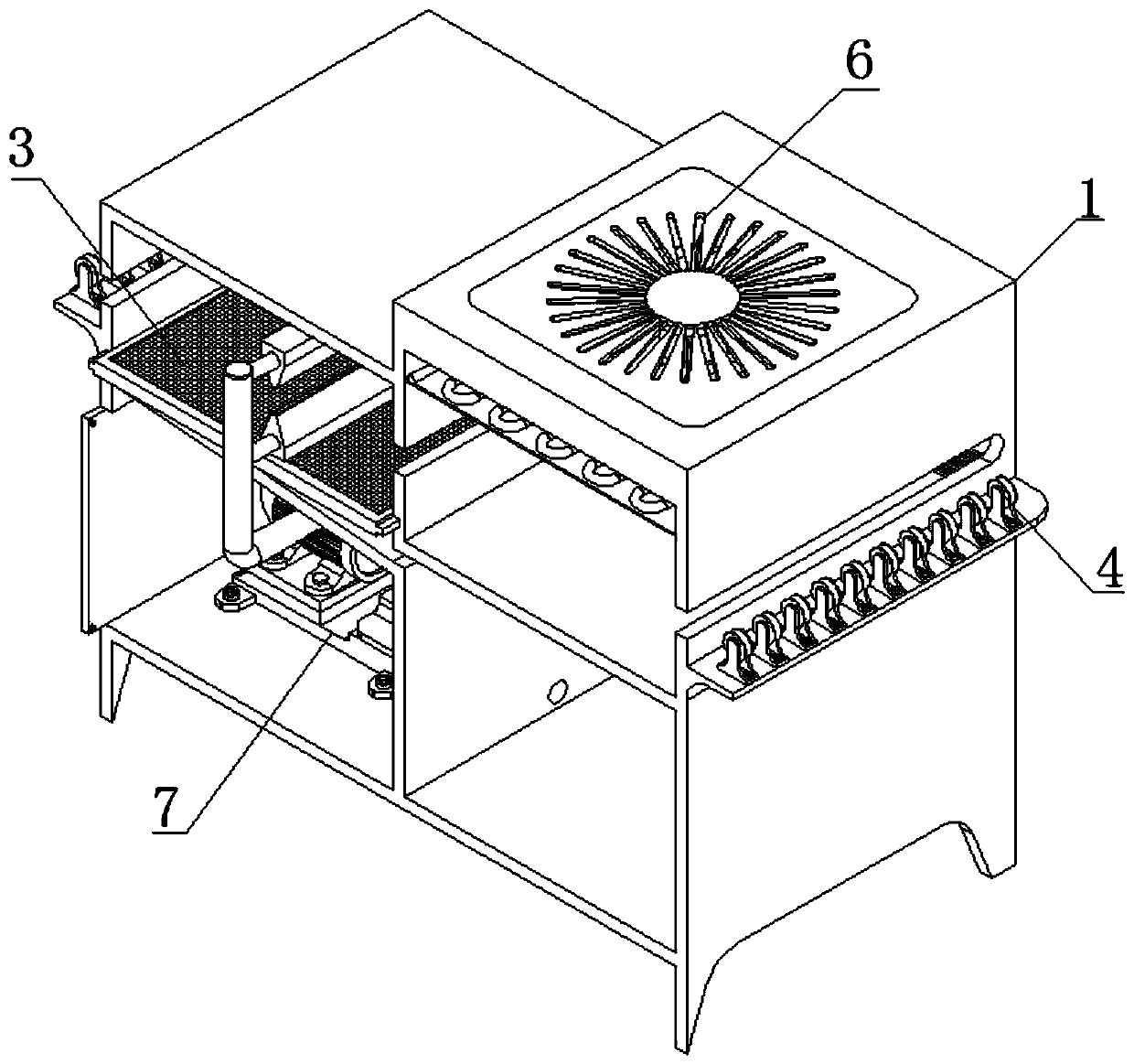

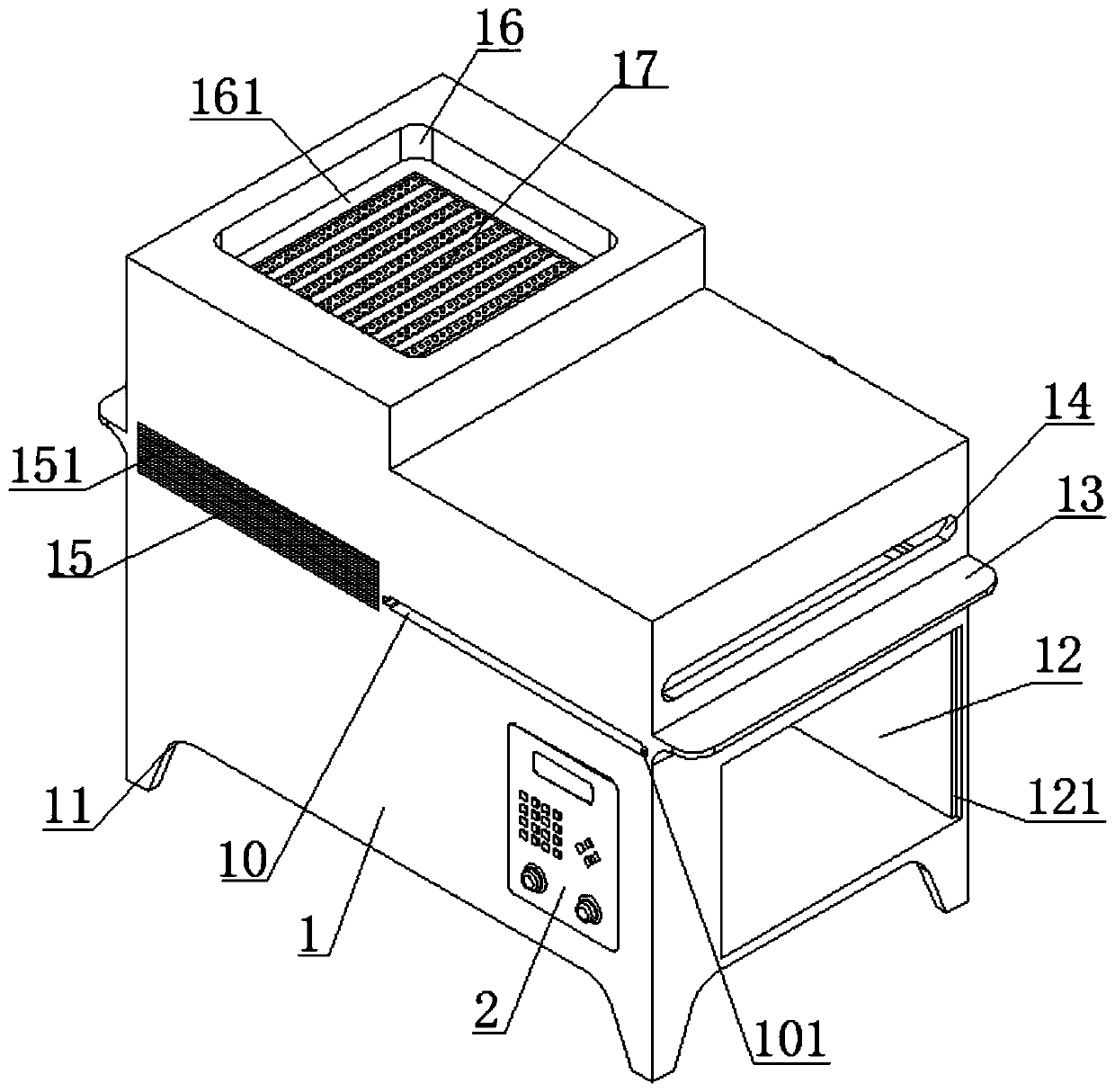

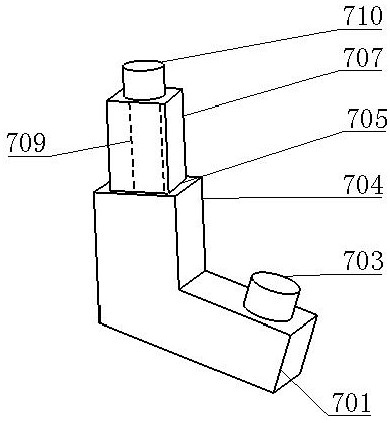

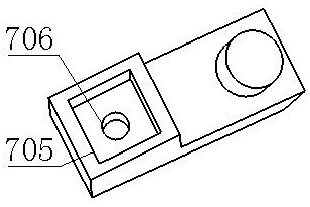

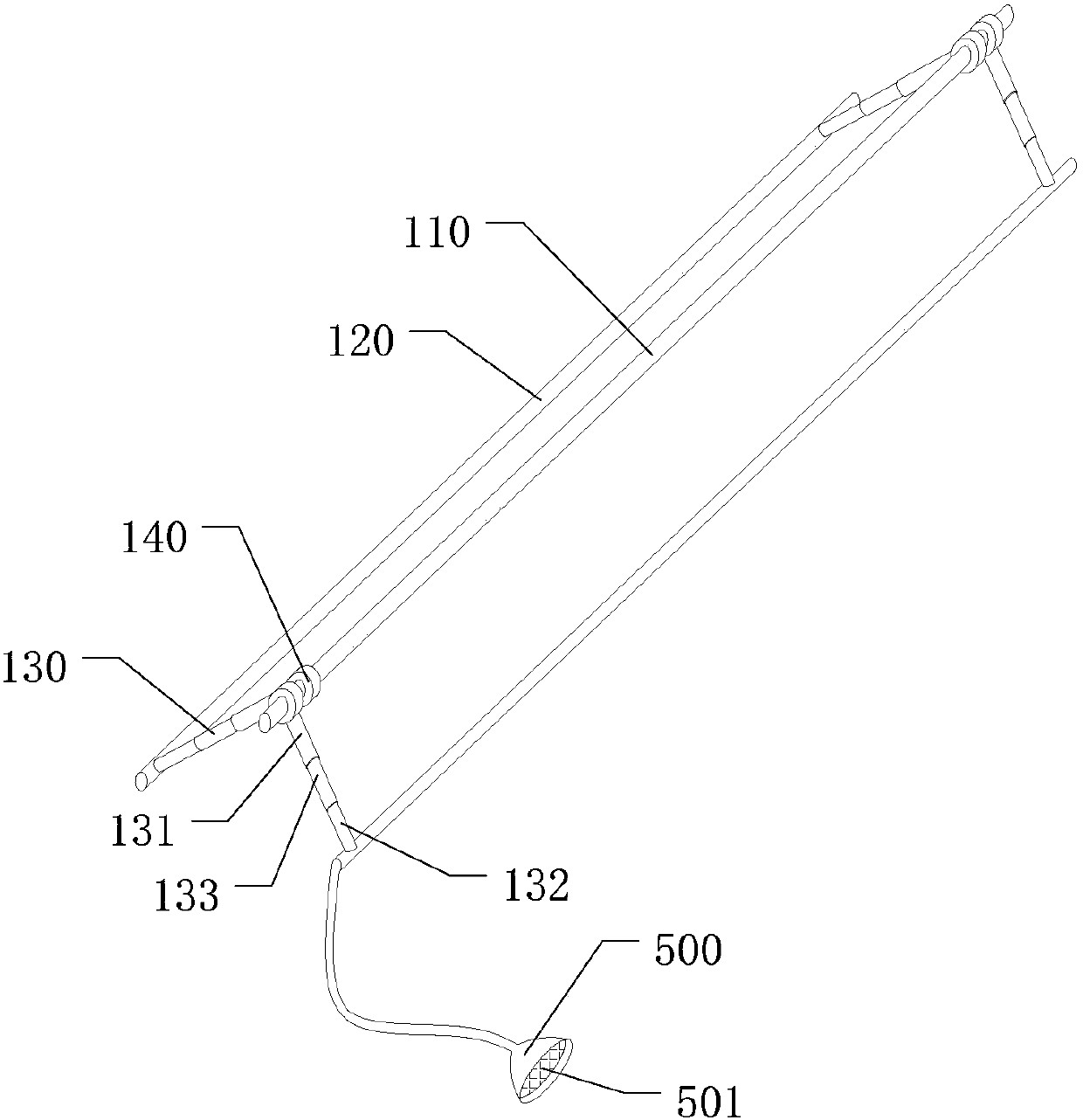

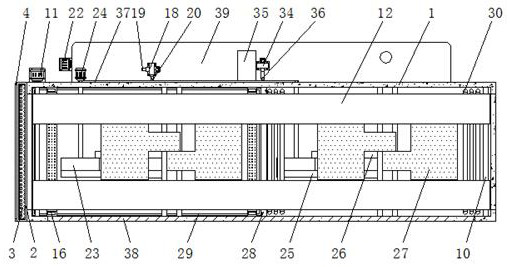

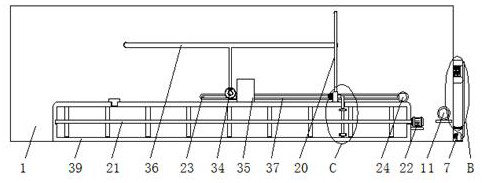

Disinfection clothes dryer and control method thereof

PendingCN113699762AWith disinfection functionEasy to blow toTextiles and paperLaundry driersThermodynamicsProcess engineering

Owner:GREE ELECTRIC APPLIANCES INC

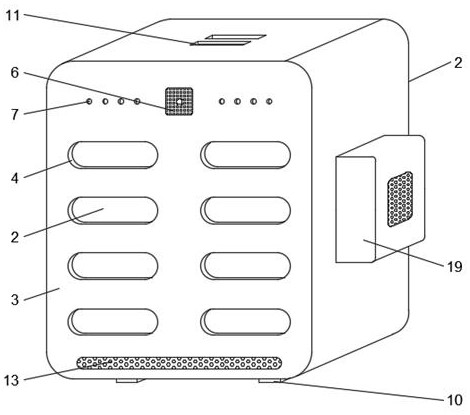

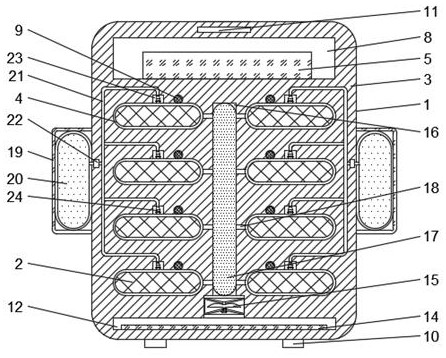

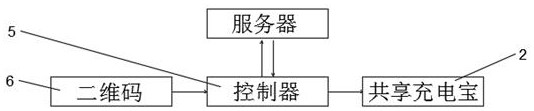

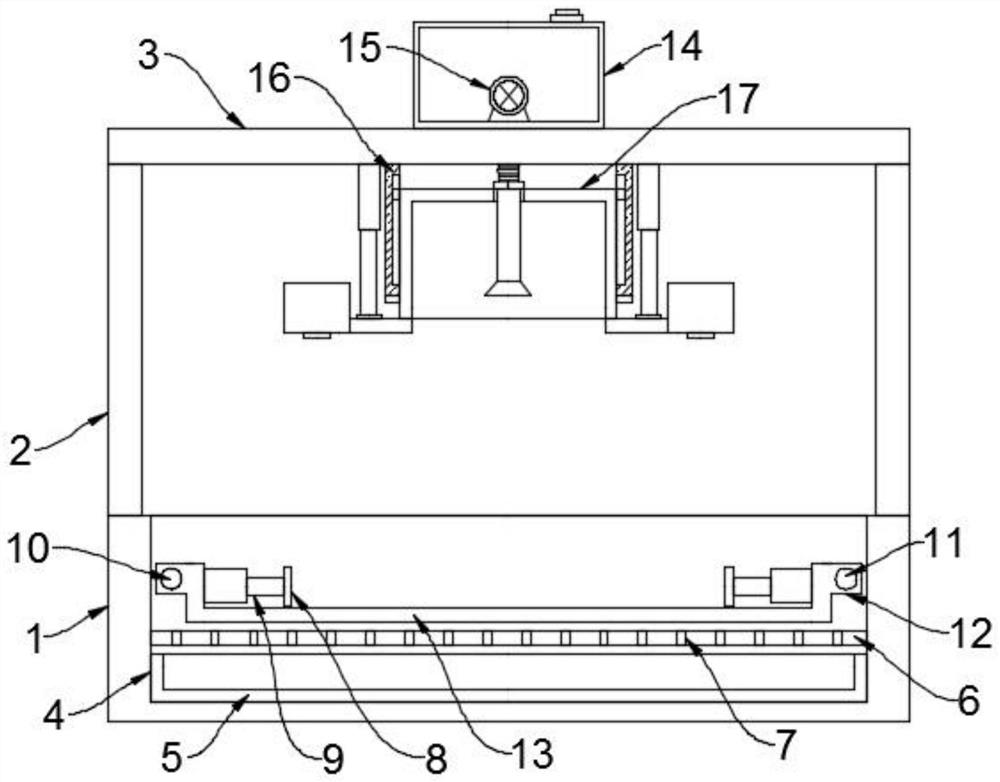

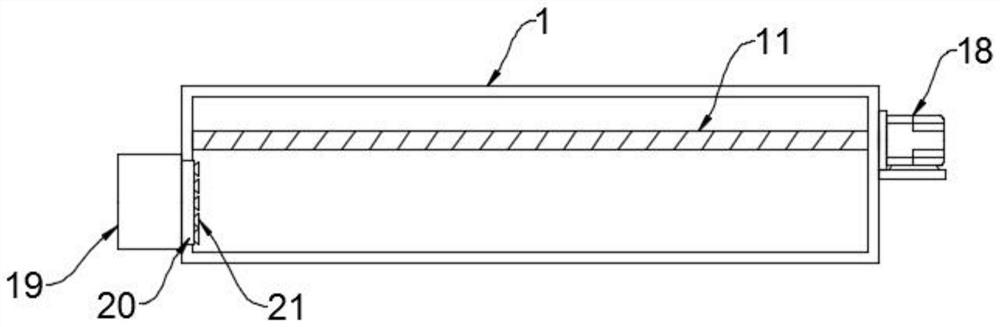

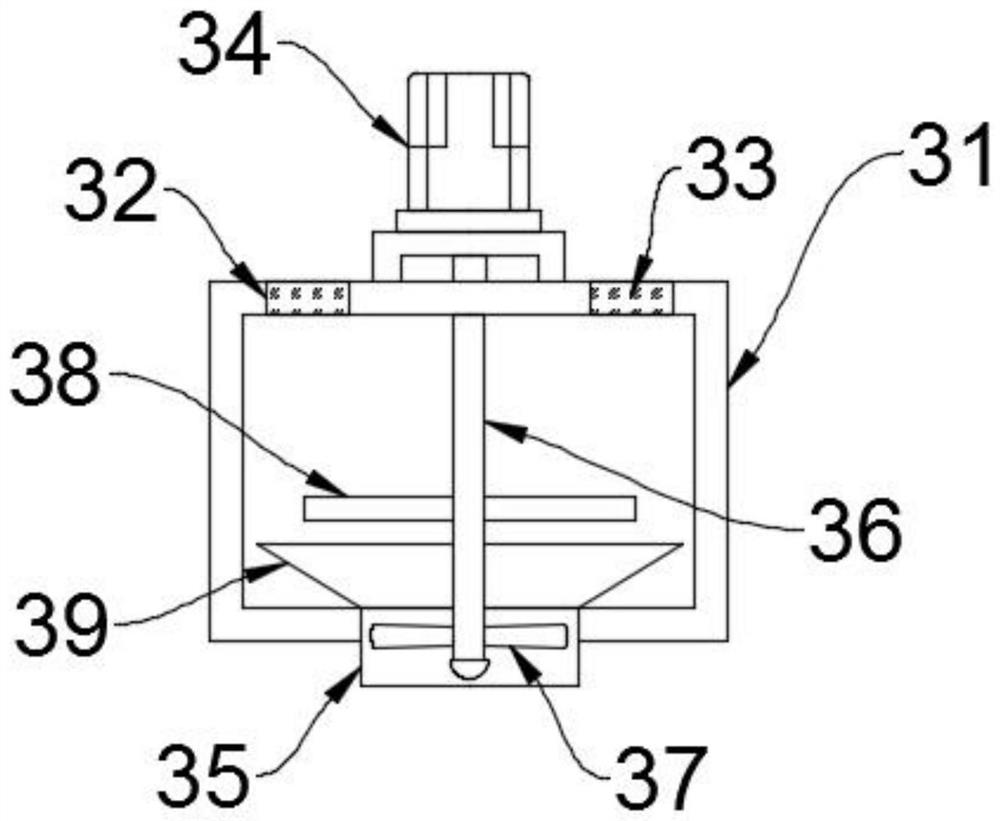

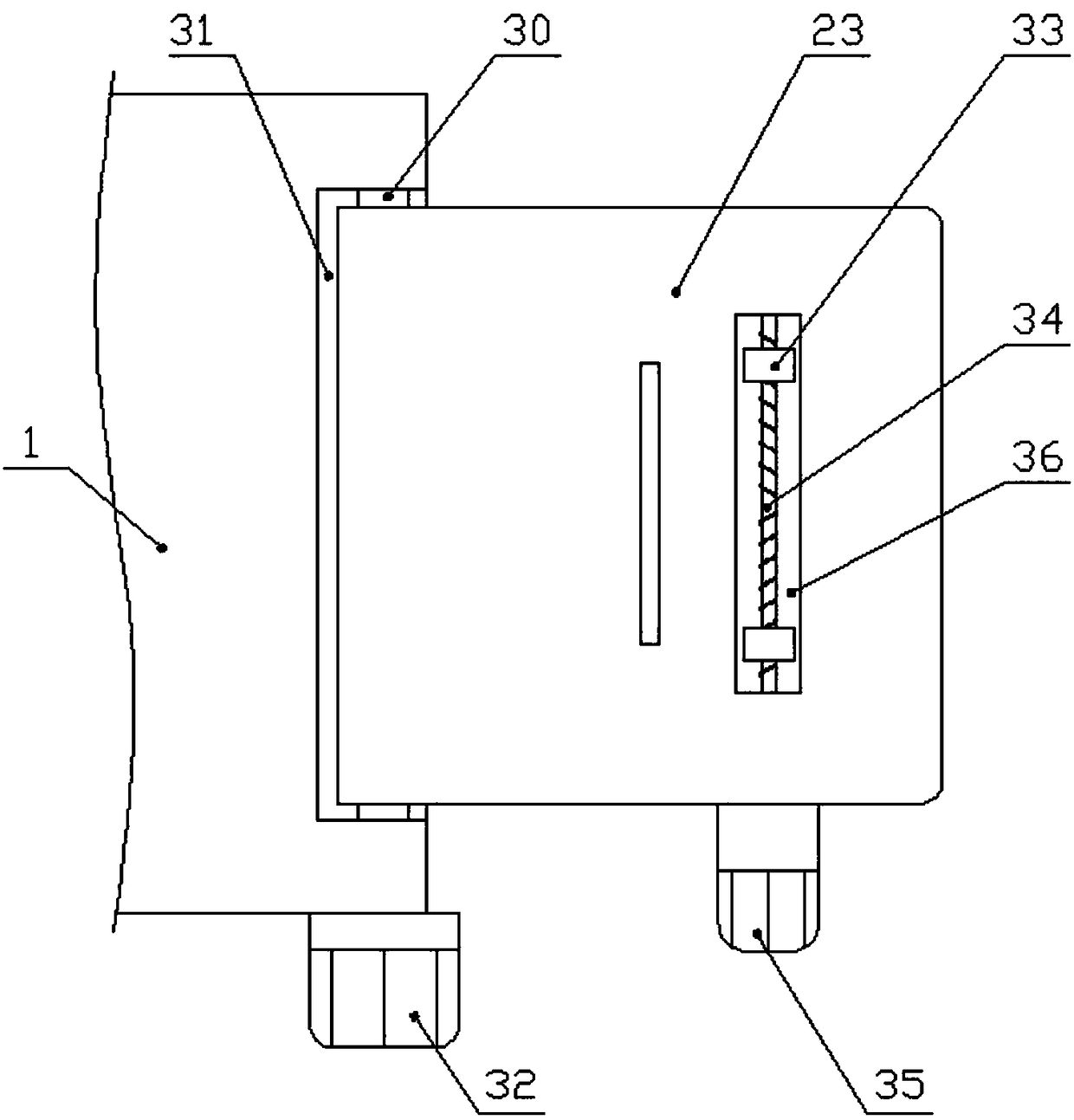

Power bank renting method and system and power bank renting equipment

PendingCN112907838AAvoid idlingLow costFire rescueApparatus for meter-controlled dispensingSpontaneous combustionCold air

The invention relates to the technical field of power bank renting, in particular to a power bank renting method and system and power bank renting equipment. According to the invention, a user can purchase a shared power bank and return the shared power bank into a shared charging device body to share the shared power bank, so that sharing benefits are obtained, and the shared power bank is prevented from being idle when not used; the cost of an operation company is also reduced; a temperature sensor and a cooling cavity are arranged in the shared charging equipment main body, so that a draught fan can conveniently suck cold air into a filtering cavity for drying, the cold air is blown to the shared power bank through a ventilation pipe, cooling is facilitated, and spontaneous combustion is avoided;a fire extinguisher and an electromagnetic valve are arranged; when a temperature sensor detects that the temperature is too high and spontaneous combustion occurs, an electromagnetic valve is opened, carbon dioxide is conveniently blown to a clamping groove through a spray head, fire extinguishing can be conveniently conducted on the shared power bank, fire hazards are reduced, and the safety performance is high.

Owner:合肥圣世寰宇科技有限公司

Surface treatment process for metal material

PendingCN112916254AImprove stabilityEasy to placeLiquid spraying apparatusSpray boothsMetallic materialsElectric machinery

The invention discloses a surface treatment process for a metal material, relates to the technical field of metal surface treatment, and aims to solve the problem that the service life of the metal material is affected due to poor spraying effect in the processing process of an existing metal material. Side plates are arranged above the workbench, the number of the side plates is two, a transverse plate is arranged above the two side plates, a paint box is arranged above the transverse plate, a pressure pump is arranged in the interior of the paint box, a groove is formed in the interior of the workbench, a partition plate is arranged in the interior of the groove, a bearing plate is arranged above the partition plate, a fixed pipe is arranged on the lower surface of the transverse plate, a movable pipe is arranged in the interior of the fixed pipe, connecting plates are arranged on the two sides below the movable pipe correspondingly, a gas collecting box is arranged on one side of each connecting plate, a second motor is installed above the gas collecting box, an air inlet pipe is arranged at the bottom of the gas collecting box, and a rotating shaft is arranged at the output end of the second motor.

Owner:苏州奥正智精密机械有限公司

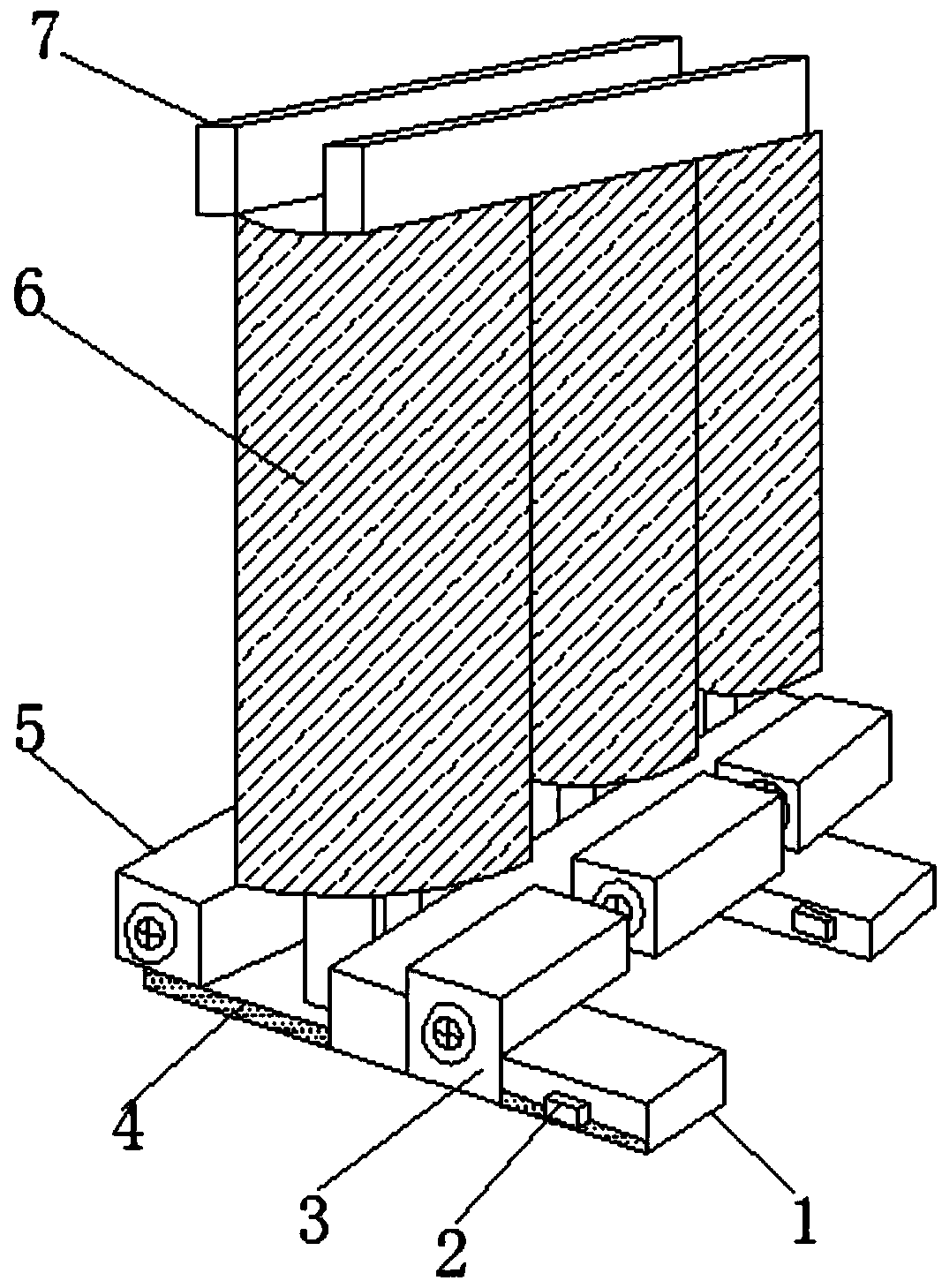

Multifunctional positive-material bimetallic band saw blade with uniform sawteeth and preparation process thereof

ActiveCN114160883AEasy clampingHeight adjustableMetal sawing tool makingMetal sawing toolsAdhesive beltEngineering

The invention discloses a multifunctional positive material bimetallic band saw blade with uniform sawteeth and a preparation process thereof, the multifunctional positive material bimetallic band saw blade comprises a bimetallic band saw blade, the bimetallic band saw blade comprises a connecting back material, the right side of the connecting back material is fixedly connected with a sawtooth piece, and the left side of the connecting back material is fixedly connected with a tooth dividing piece. According to the grinding method for the multifunctional material correcting bimetallic band saw blade with the uniform sawteeth, through mutual cooperation of the base, the spring and the top clamp, the bimetallic band saw blades with different thicknesses can be conveniently clamped and fixed, the height of a second grinding wheel can be adjusted by rotating a connecting lead screw, and the distance between the first grinding wheel and the second grinding wheel is made to be matched with the size of the bimetallic band saw blade; through mutual cooperation of the collecting box, a winding drum, an adhesive tape and a micro motor, scraps falling into the collecting box can be conveniently adhered in time, the scraps are automatically wound and collected by the adhesive tape, later-stage re-cleaning is not needed, and through mutual cooperation of a bearing box and a fan, flying scraps can be conveniently blown into the collecting box.

Owner:江苏天硕合金材料有限公司

Environment-friendly knock-out barrel

InactiveCN109290553AEasy to collectFor subsequent collectionDispersed particle filtrationSprayerEngineering

The invention discloses an environment-friendly knock-out barrel. The environment-friendly knock-out barrel comprises a base, support bases are arranged in the middle of the upper end of the base at intervals, a roller is arranged over the support bases, the inner wall of the roller is provided with an inner thread, a driving mechanism used for driving the roller to rotate is arranged at the upperend of the base, and sand outlet holes are formed in the portion, on one side of the discharging end, of the side wall of the roller; the support bases are arranged at the upper end of the base, an outer pipe with the two open ends is arranged at the upper ends of the support bases, the roller is arranged in the outer pipe, the outer wall of the roller is provided with an outer thread, and a sanddischarging hole is formed in the portion, on the far side of the discharging end, of the bottom wall of the outer pipe; and brackets are arranged on the portions, on the two sides of the open ends of the outer pipe, of the upper end of the base, a ventilation pipe is arranged between the brackets on the two sides, sprayer heads are arranged on the portions, in one section of the roller, of the side wall of the ventilation pipe, a dust removing device is arranged at the upper end of the outer pipe, and a feeding device is arranged on the portion, on one side of the feeding end, of the base. According to the environment-friendly knock-out barrel, feeding is easy; and meanwhile, the dust removing device is arranged in the middle section of the roller, and then it is guaranteed that dust cannot overflow.

Owner:XINHUANG YUANDA MACHINERY CASTING

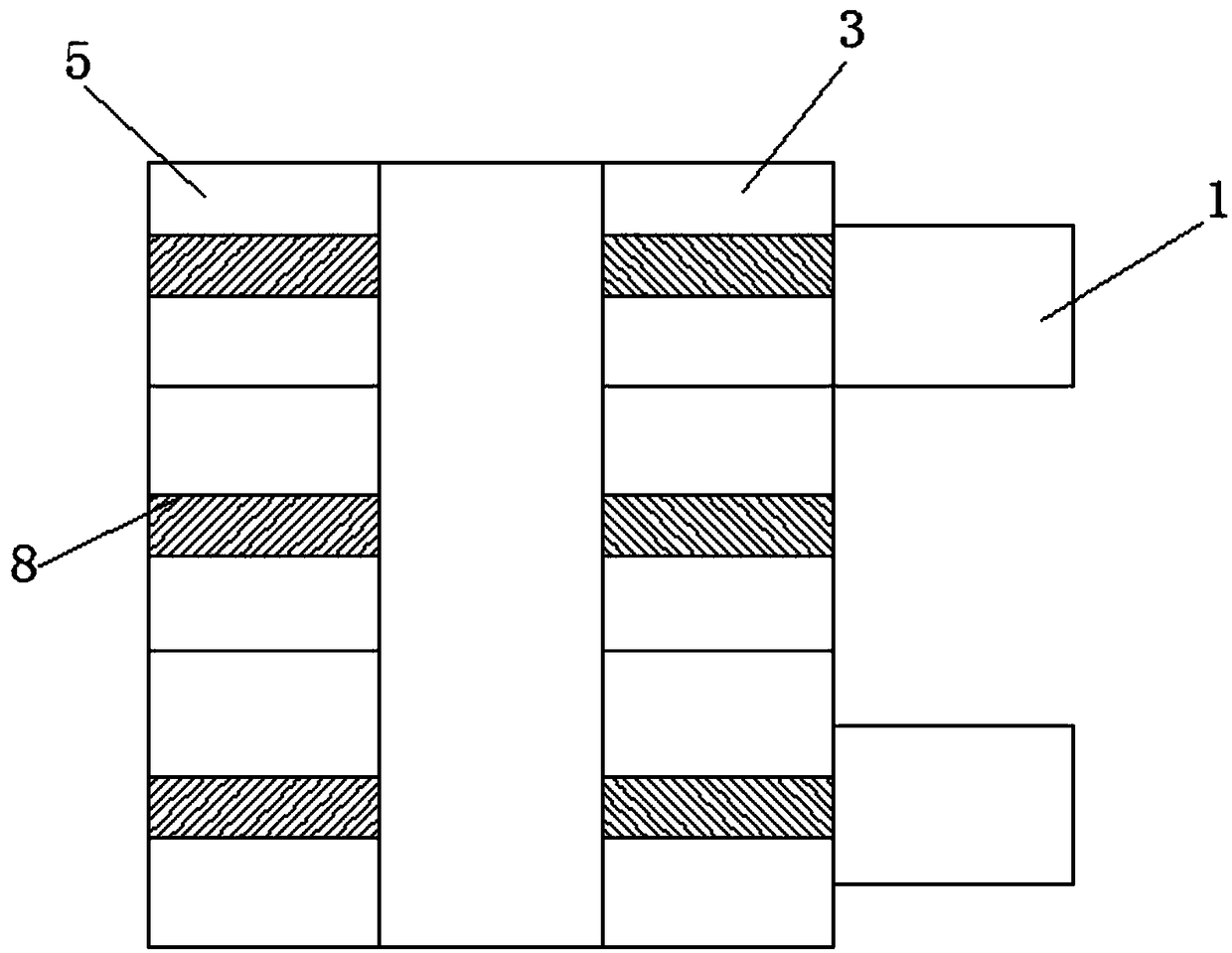

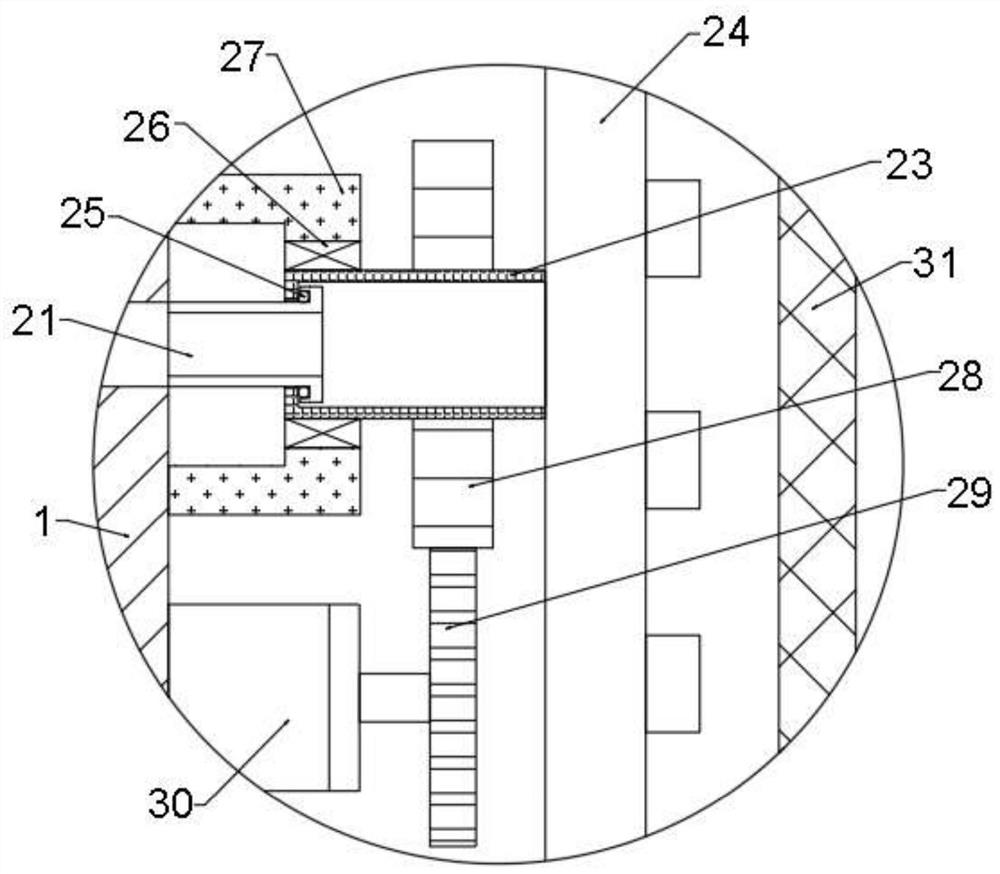

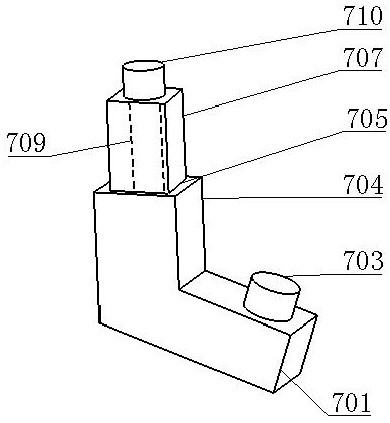

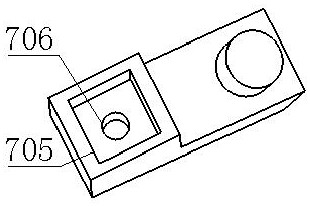

Transformer core support convenient to maintain

InactiveCN109473257AEasy to blow toKeep dryDrying gas arrangementsTransformers/inductances magnetic coresTransformerOperation mode

The invention discloses a transformer core support convenient to maintain. The transformer core support convenient to maintain comprises a limiting clamping seat, a transformer core and a base. The two sides of the top of the transformer core are fixedly connected with shielding plates. The transformer core support is reasonable in design, convenient to use and very suitable for the transformer core, by means of the cooperative operation mode of first chucks and second chucks and under the cooperation of clamping blocks and clamping grooves, when the transformer core needs to be fixed, firstly, the clamping blocks at the bottom of the transformer core align at the clamping grooves in the tops of the first chucks and the second chucks, then the transformer core is put down, the clamping blocks and the clamping grooves are clamped for cooperation, then an air cylinder is started, the air cylinder pushes a limiting block to clamp rollers, the first chucks are fixed, thus, the transformercore is fixed, during detachment and maintenance, it is only needed to adjust the air cylinder to shrink, the limiting block is away from the rollers, the first chucks can slide, the transformer coreis detached to be maintained, and the transformer core support is simple, convenient and suitable for being widely popularized.

Owner:TAIZHOU TIANLI IRONCORE MFG

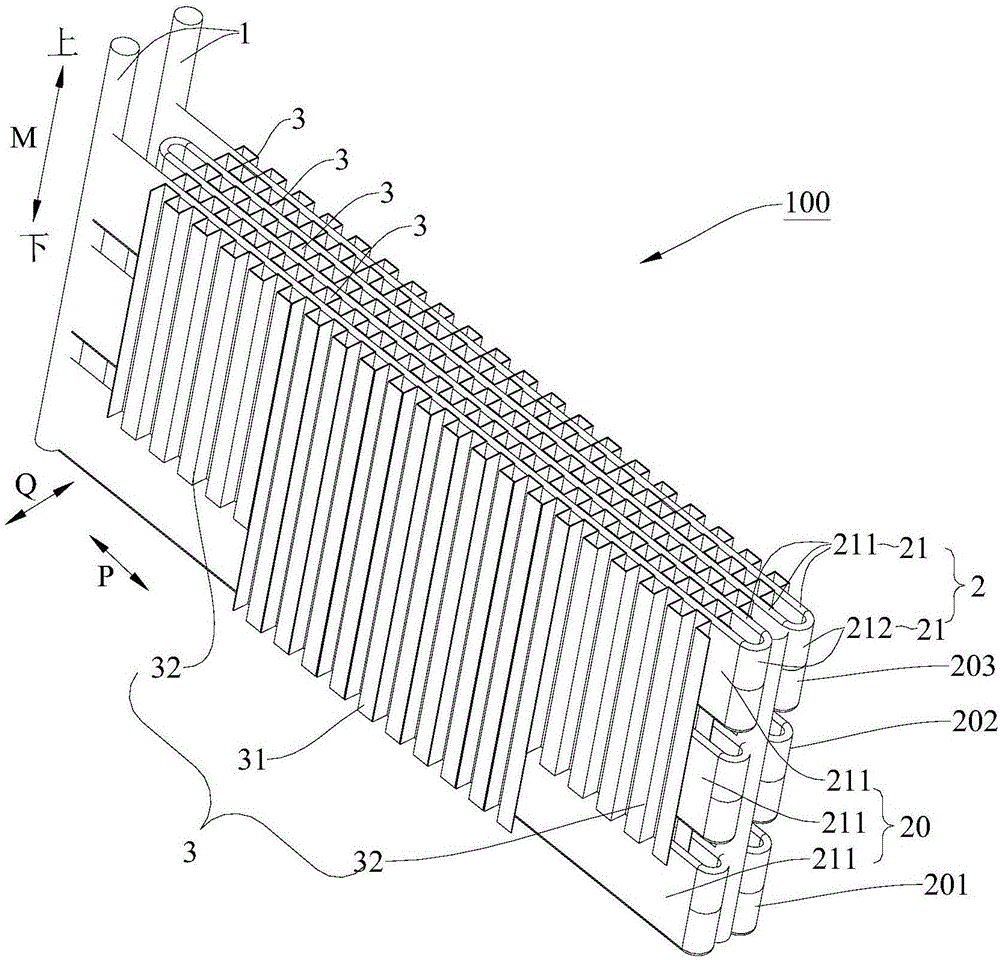

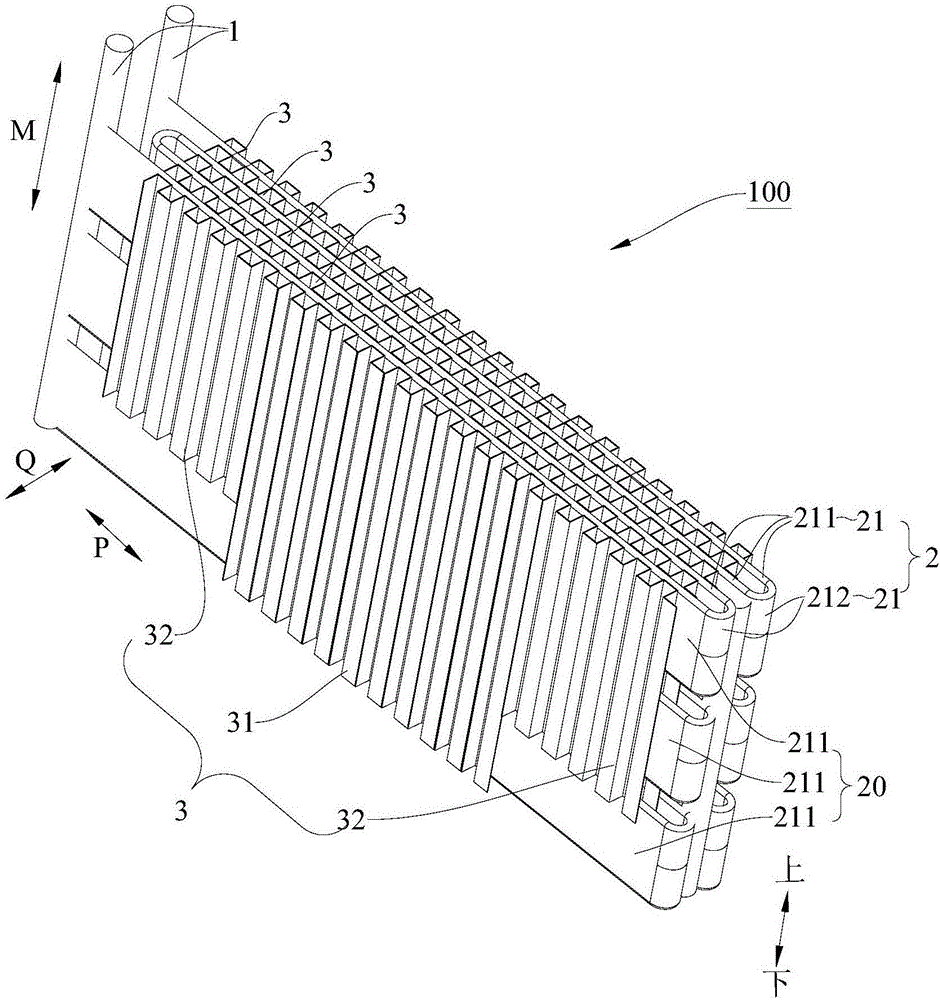

Microchannel heat exchanger, refrigerator and air-cooled refrigerator

InactiveCN106403643ASolve the large amount of hanging waterSolve inexhaustible problemsDomestic refrigeratorsEvaporators/condensersEngineeringRefrigerated temperature

The invention discloses a microchannel heat exchanger, a refrigerator and an air-cooled refrigerator. The microchannel heat exchanger comprises two collecting pipes, multiple heat exchange pipes and at least one fin; the two collecting pipes are arranged in parallel; two ends of the multiple heat exchange pipes are connected with the two collecting pipes respectively; the multiple heat exchange pipes are bent in length directions of the heat exchange pipes to form multiple pipe layers; and each fin is arranged between the adjacent two pipe layers or is arranged on the outer side of the outmost pipe layer, extends in a corrugated shape in the extending direction of the heat exchange pipes, extends continuously in the extending direction of the collecting pipes and is connected with at least two heat exchange pipes in the pipe layer where the fin is located. According to the microchannel heat exchanger, in the defrosting process, defrosted water on surfaces of the fins can accumulate to form water drops, the water drops can slip off smoothly and can be drained along the continuous fins, problems that the amount of water on the surfaces of the fins is relatively large and the water cannot be drained are solved, and the condition that the heat exchange efficiency is affected due to the fact that stubborn ice is produced on the surface of the microchannel heat exchanger can be prevented.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

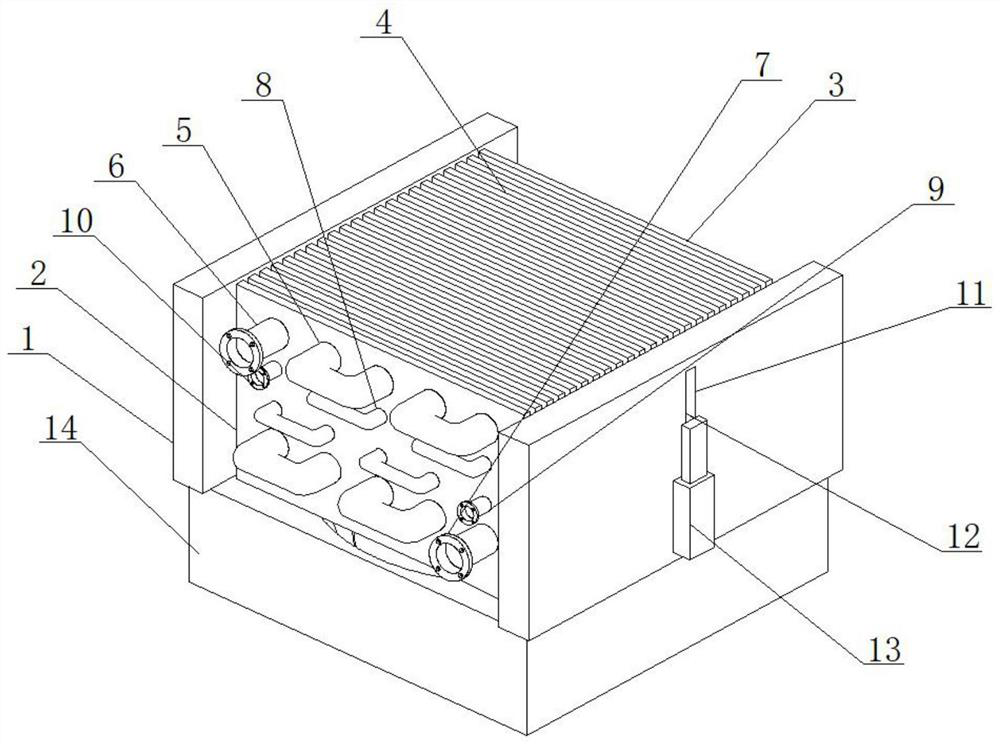

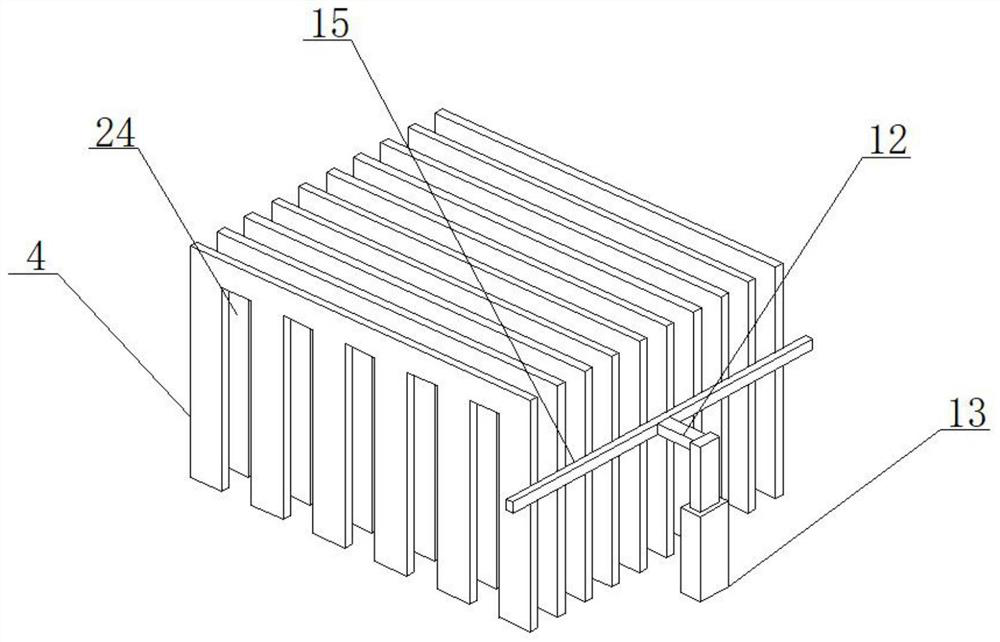

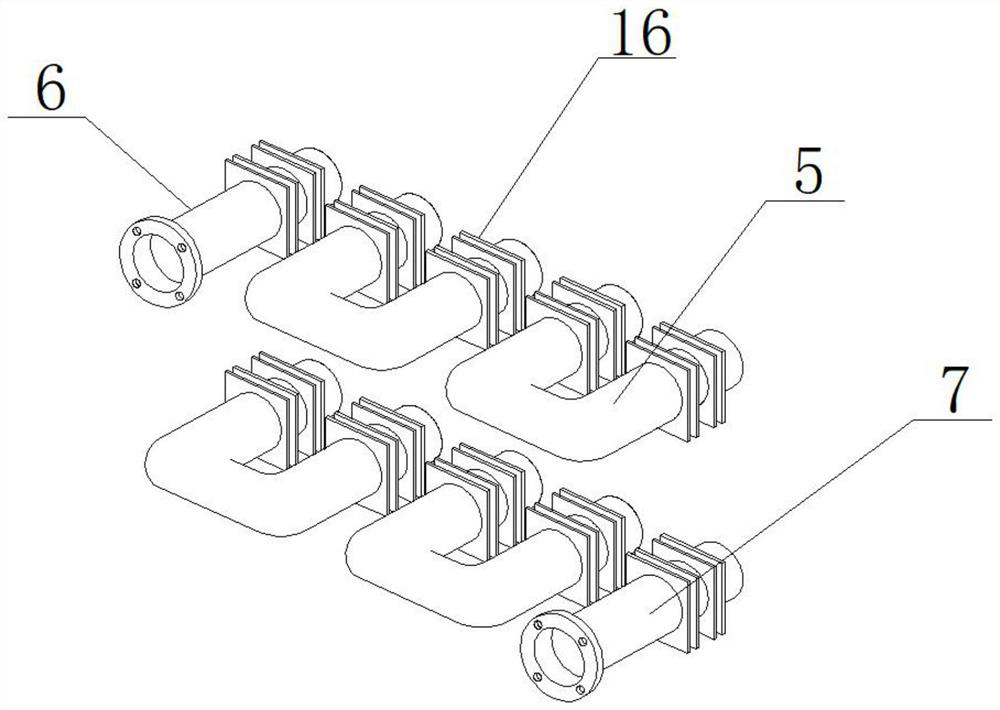

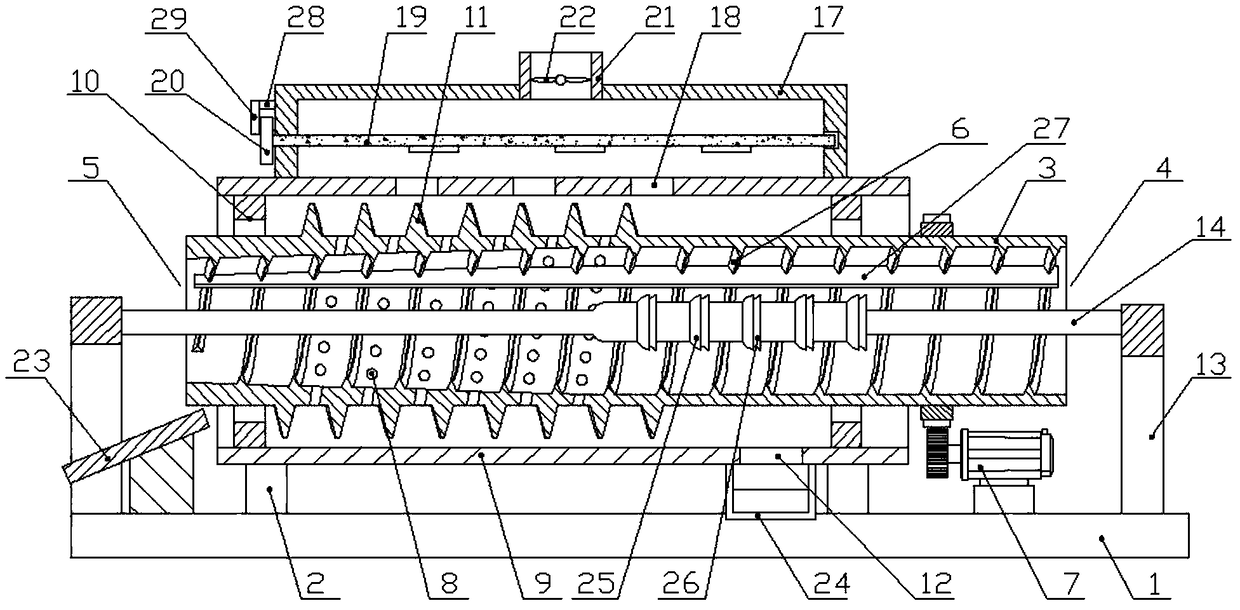

Cooling treatment device used for acid fracturing truck

InactiveCN113187599AQuick removalEasy to blow toInternal combustion piston enginesDomestic cooling apparatusAcid fracturingTruck

The invention provides a cooling treatment device used for an acid fracturing truck. The cooling treatment device comprises a cooling treatment device body, the cooling treatment device body comprises a supporting plate, a mounting plate and a fixing plate are welded on the supporting plate, fin plates are mounted between the mounting plate and the fixing plate, pipelines are mounted on the mounting plate and the fixing plate, a liquid outlet pipe and a liquid inlet pipe are mounted at the two ends of the pipelines correspondingly, cooling pipes are mounted at the bottoms of the pipelines, and a water inlet and a water drain opening are mounted at the two ends of the cooling pipes correspondingly. When the cooling treatment device used for the acid fracturing truck is used, the fin plates are pushed to move up and down through an electric push rod, and therefore after heat in the pipelines is adsorbed for a certain time, the fin plates at the high-temperature position are separated from clamping plates, the cooled fin plates move up and down to make contact with the clamping plates to absorb heat again, heat absorption changes are conducted through cold and heat alternation, and therefore the heat in the pipelines is rapidly removed.

Owner:HUBEI PETROKH MACHINE MFG

Knock-out barrel

The invention discloses a knock-out barrel. The knock-out barrel comprises a base, a supporting base is arranged in the middle of the upper end of the base in a spaced manner, a roller is arranged above the supporting base, an inner thread is arranged on the inner wall of the roller, a driving mechanism for driving the roller to rotate is arranged at the upper end of the base, a sand discharging hole is formed in the position, on the side of the discharging end, of the side wall of the roller, the supporting base is arranged at the upper end of the base, the upper end of the supporting base isprovided with an outer pipe with two ends opened, the roller is arranged in the outer pipe, an outer thread is arranged on the outer wall of the roller, a sand discharging hole is formed in the position, on the far side of the discharging end, of the bottom wall of the outer pipe, supports are arranged at the positions, on the two sides of the open ends of the outer pipe, of the upper end of thebase, a ventilation pipe with the hollow inner is arranged between the supports on the two sides, nozzles are formed in the position of the segment, located in the roller, of the side wall of the ventilation pipe, and a dust removal device is arranged on the upper end of the outer pipe. The knock-out barrel can easily collect molding sand, and meanwhile it is ensured that the dust cannot flow out.

Owner:XINHUANG YUANDA MACHINERY CASTING

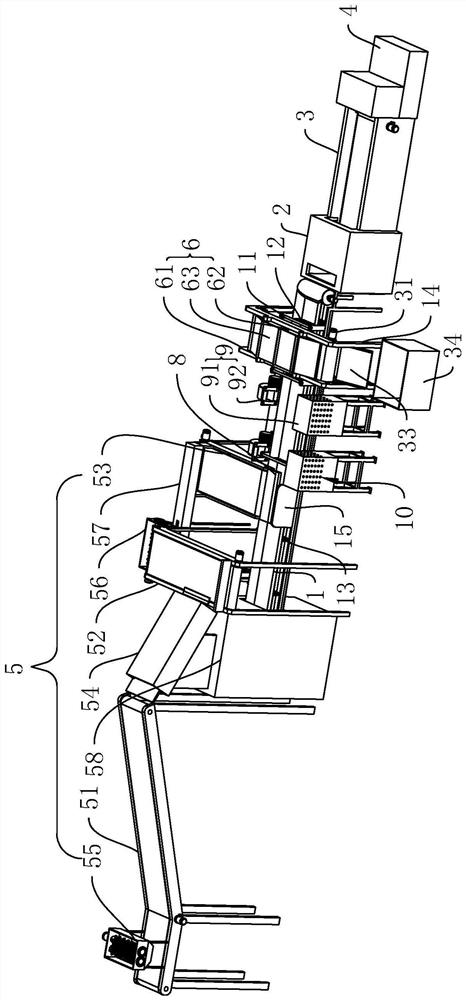

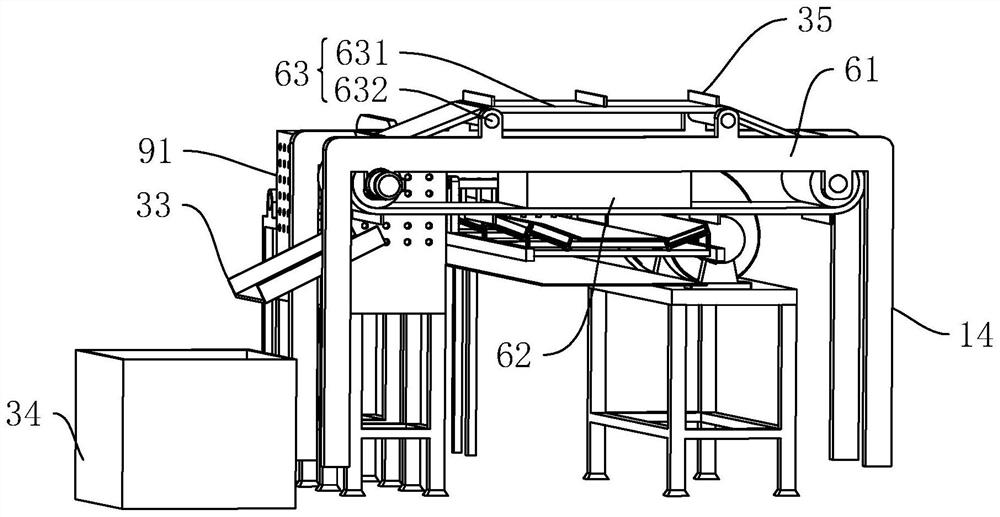

Waste glass treatment system

ActiveCN113385518AEasy to recycleEasy to removeSolid waste disposalGrain treatmentsNonferrous metalIron removal

The invention relates to a waste glass treatment system. The system sequentially comprises a coarse crushing device, a first conveying belt, a flushing machine, a non-ferrous metal sorting machine and a crushing machine according to the sequence of waste glass treatment procedures, and an iron removing mechanism is erected on the first conveying belt; the iron removing mechanism comprises a fixing frame, the first conveying belt and a first iron attracting block, supporting legs are fixedly installed at the bottom of the fixing frame, and the fixing frame is erected above the first conveying belt through supporting legs; the first conveying belt comprises an annular belt and a plurality of first transmission rollers being abutted against the annular belt, at least one first transmission roller is connected with a first motor driving the first transmission rollers to rotate, and the first transmission rollers are rotationally installed on the fixing frame; a plurality of first baffles are fixedly installed on the outer surface of the annular belt, the first baffles are arranged at intervals in the transmission direction of the annular belt, the first iron attraction block is installed on the fixing frame, and the annular belt surrounds the first iron attraction block. The waste glass treatment system has the effect that the waste glass treatment efficiency of the waste glass treatment system is improved.

Owner:莆田市日晶玻璃制品有限公司

Chemical fiber filament elasticity-improving process

InactiveCN111005183AEasy to assembleEasy to useSucessive textile treatmentsLiquid/gas/vapor removalFiberThermodynamics

The invention discloses a chemical fiber filament elasticity-improving process. The chemical fiber filament elasticity-improving process comprises a machine body, wherein an oil storage cavity is formed in one side of the lower half part of the interior of the machine body, and an oil pump is arranged on the other side; and an oil passing cavity is formed in a position, aligned with the oil pump,of the upper half part of the machine body, and a drying cavity is formed in a position aligned with the oil storage cavity. By virtue of the chemical fiber filament elasticity-improving process, theproblem that the surface of the chemical fiber filament is not uniform in oiling to cause that the oiling of the chemical fiber filament is not up to the standard when an existing chemical fiber filament oil passing device is used for performing oil passing on the chemical fiber filaments, and the problem that the packaging of the chemical fiber filament is not facilitated caused by too oily chemical fiber filament due to that the existing chemical fiber filament oil passing device has no dying function can be solved; and by virtue of improvement and optimization of the chemical fiber filamentoil passing device, uniform oiling on the surface of the chemical fiber filament can be achieved when the chemical fiber filament is oiled, so that the uneven oiling on the surface of the chemical fiber filament is avoided, and the oiled chemical fiber filament can be dried quickly through the chemical fiber filament oiling device.

Owner:湖州练市天龙纺织有限公司

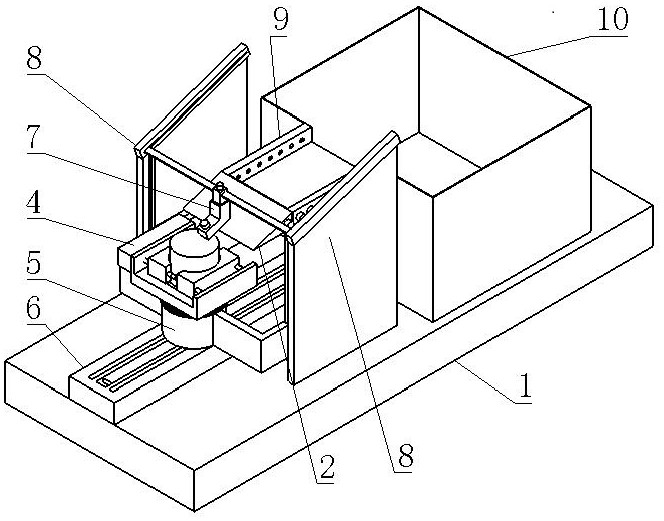

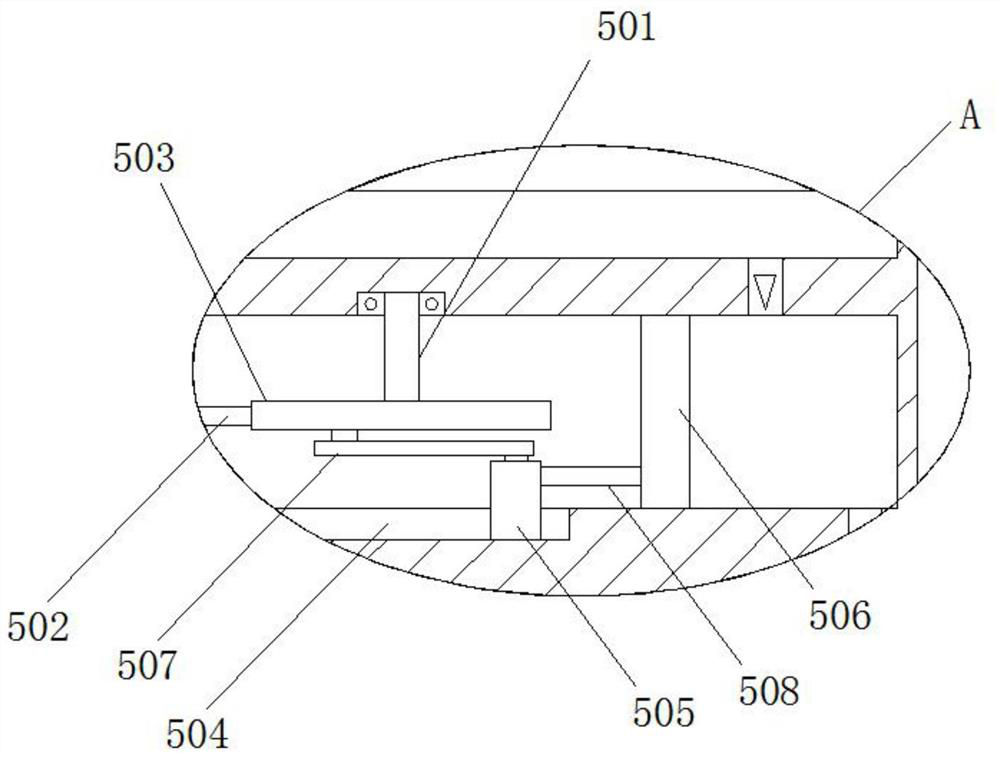

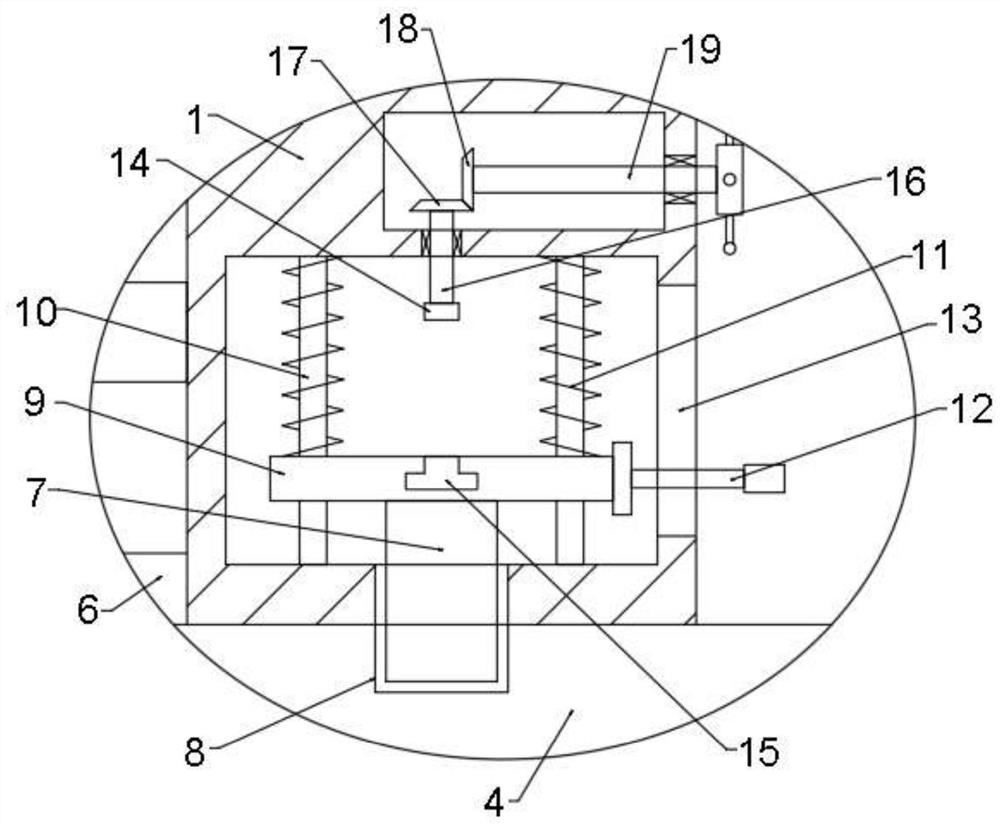

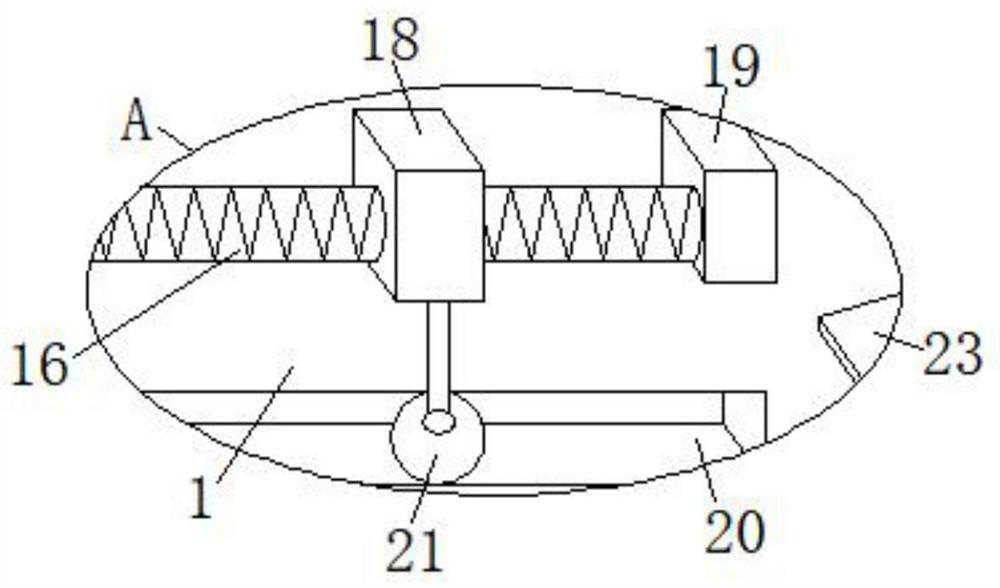

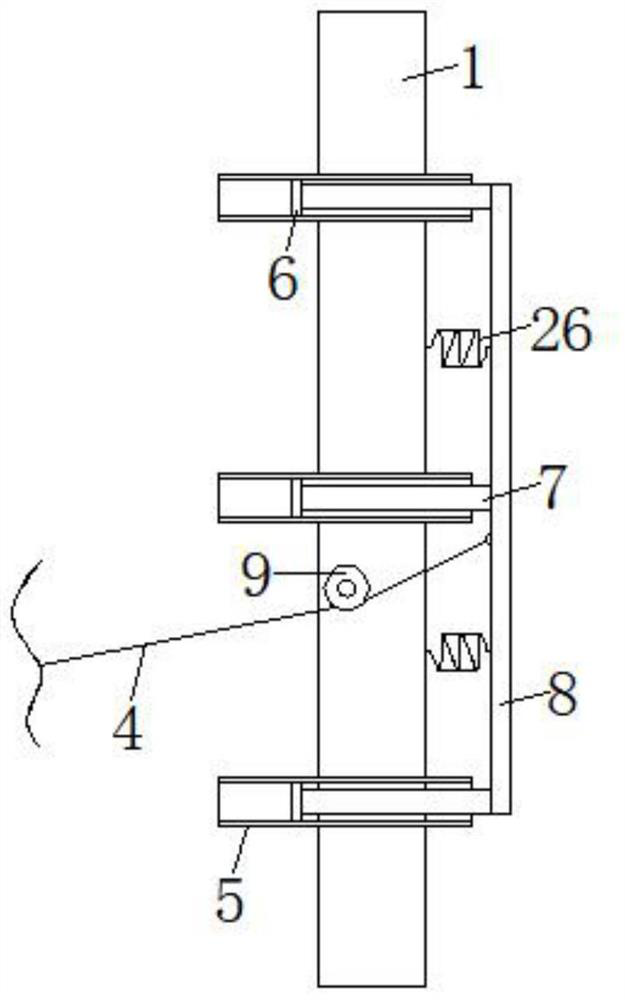

Intelligent gynecological tumor pathological section treatment system

ActiveCN113029723AEasy to holdEasy accessWithdrawing sample devicesPreparing sample for investigationControl systemGynecology department

The invention belongs to the technical field of medical instruments, relates to the technical field of intelligent manufacturing, and particularly discloses an intelligent gynecological tumor pathological section treatment system which comprises a section system and a control system matched with the section system. The section system comprises a horizontally-arranged base, and a wax block moving device is arranged on the base. A slicing knife matched with the wax block moving device is arranged above the wax block moving device; The wax block moving device comprises a container, a clamping mechanism is arranged on the container, a lifting mechanism is arranged below the container, and an advancing and retreating mechanism is arranged below the lifting mechanism; and the slicing knife is fixedly connected with the base. The invention provides an intelligent gynecological tumor pathological section processing system capable of automatically slicing and paving.

Owner:HENAN CANCER HOSPITAL

Drying device for beam splitter prism processing

InactiveCN112797767ARaise the inner cavity temperatureReasonable structural designDrying solid materials without heatDrying gas arrangementsBeam splitterDrive shaft

The invention discloses a drying device for beam splitter prism processing. The drying device comprises a vertical frame, the top of the vertical frame is connected with a drying base, the center of the top of the drying base is connected with a driving motor, an inner cavity of the drying base is provided with a heating chamber, an air supply chamber and a drying chamber from top to bottom, the power output end of the bottom of the driving motor is connected with a driving shaft, the end, extending into the drying chamber, of the driving shaft is connected with a driving gear I, guide grooves are symmetrically formed in the left side and the right side of an inner cavity of the drying chamber, reciprocating lead screws are rotationally connected into the guide grooves, moving blocks are in threaded connection with the outer walls of the reciprocating lead screws, air spraying heads are arranged at the ends, close to the driving shaft, of the moving blocks, first rotating rods are rotationally connected to the left end and the right end of a transmission cavity, the section, located in the inner cavity of the drying chamber, of each first rotating rod is connected with a plurality of containing blocks, and a plurality of clamping grooves are formed in each containing block. The drying device is reasonable in structural design, the lens drying speed is increased, gas can be sprayed to a lens more uniformly, and the overall drying effect of the device is improved.

Owner:宜都全合光电有限公司

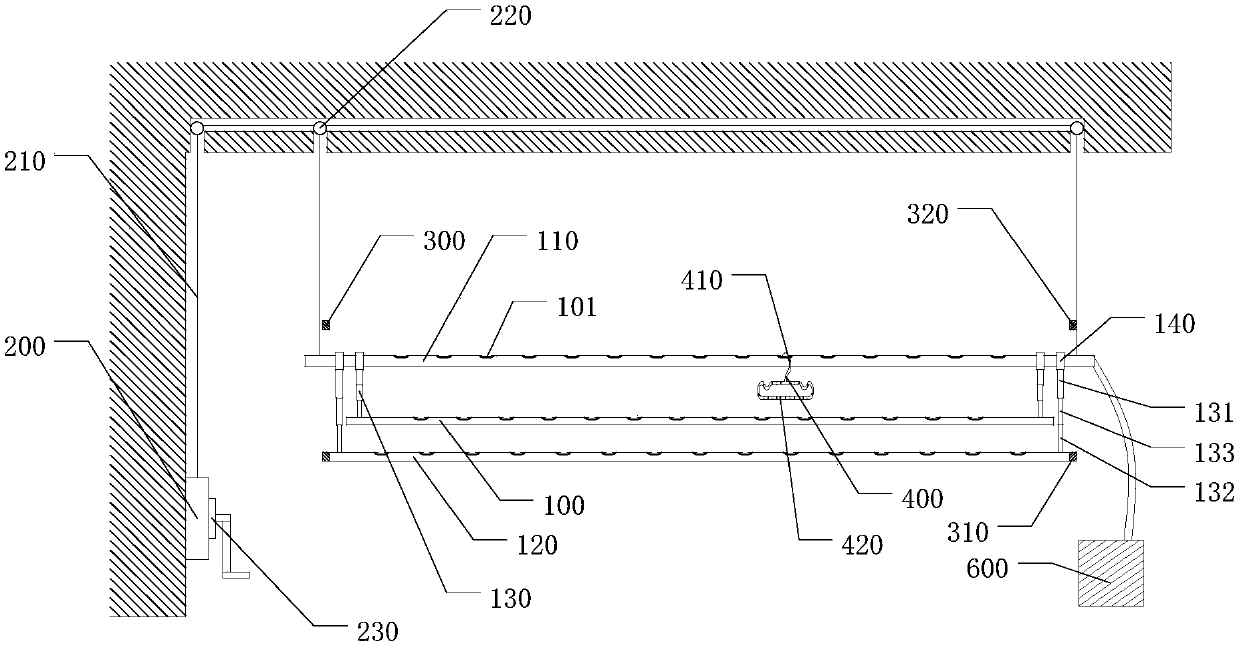

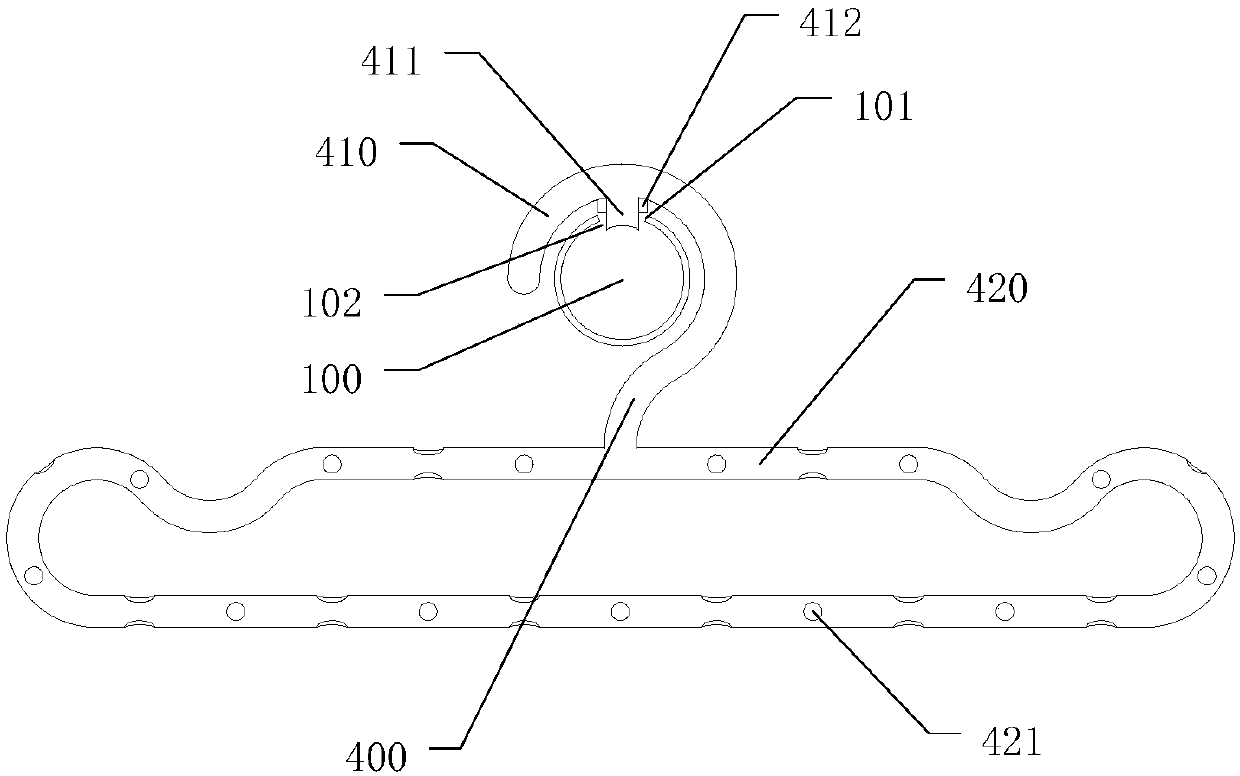

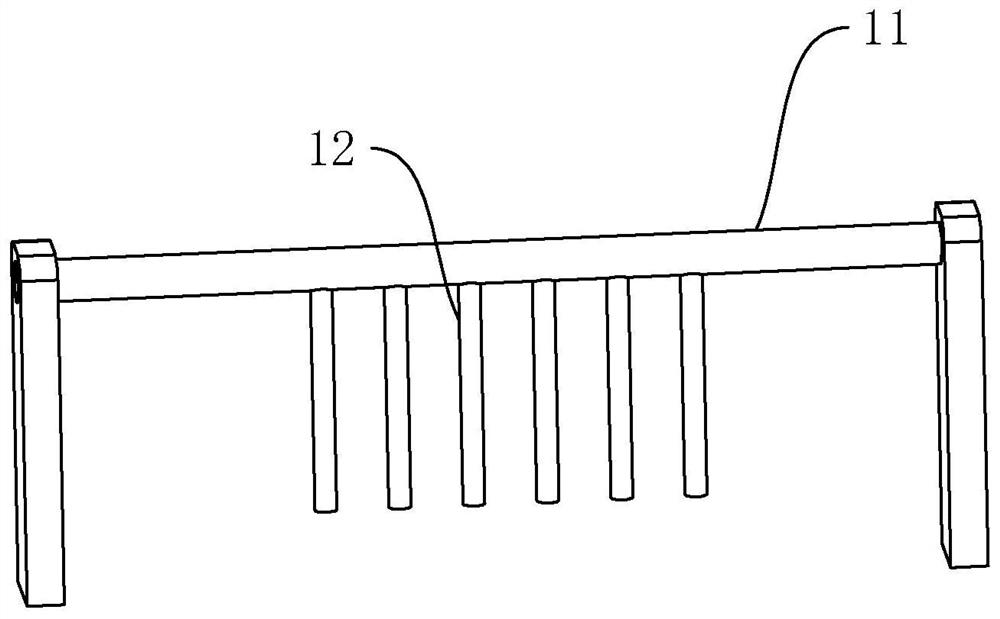

Clothes airing device capable of improving air flow

ActiveCN108035129ABig spaceIncrease contact surfaceTextiles and paperLaundry driersAirflowEngineering

Owner:合肥源康信息科技有限公司

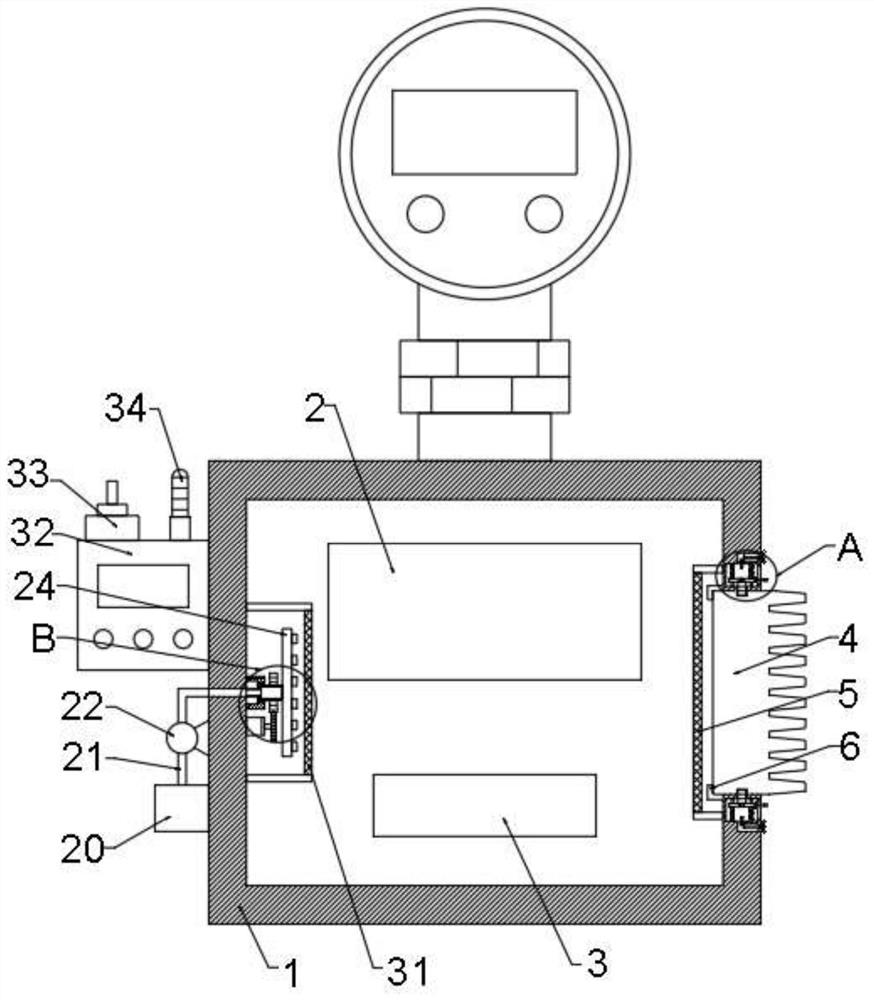

Overheating protection device for protecting automatic instrument

ActiveCN112423541AEasy dischargeEasy to blow toModifications by conduction heat transferCold airElectric machinery

The invention discloses an overheating protection device for automatic instrument protection. The device comprises an instrument body, a display module and a cooling fin, wherein the instrument body is internally provided with the display module, and the lower side of the display module is provided with an instrument operation module. When the overheating protection device is used, heat generatedinside the instrument body during working can be conveniently discharged to the outside through the arranged cooling fin, the temperature inside the instrument body can be conveniently monitored through the thermocouple, and when the temperature inside the instrument body is high, the alarm gives an alarm through the control box to remind a worker to detach the cooling fin from the instrument body, and cold air is conveyed to the interior of the instrument body through the arrangement of the cooler, so that air circulation in the instrument body is promoted, the interior of the instrument bodyis cooled, and the heat dissipation effect is ideal; and the motor can drive the vertical pipe to rotate, so that cold air can be conveniently and evenly blown into the instrument body, and the heatdissipation efficiency of the instrument body is improved.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

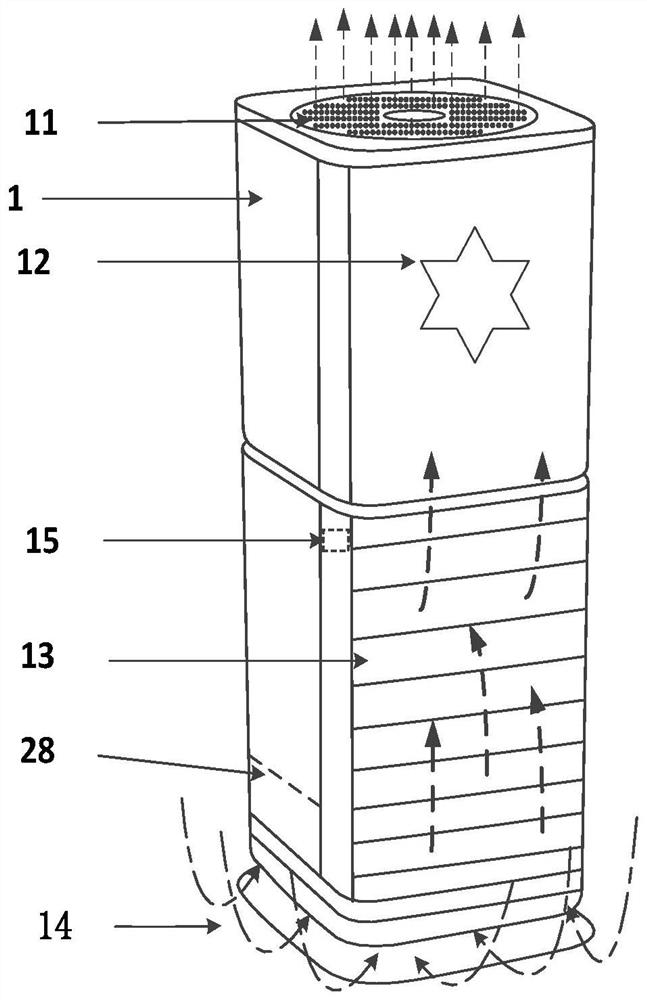

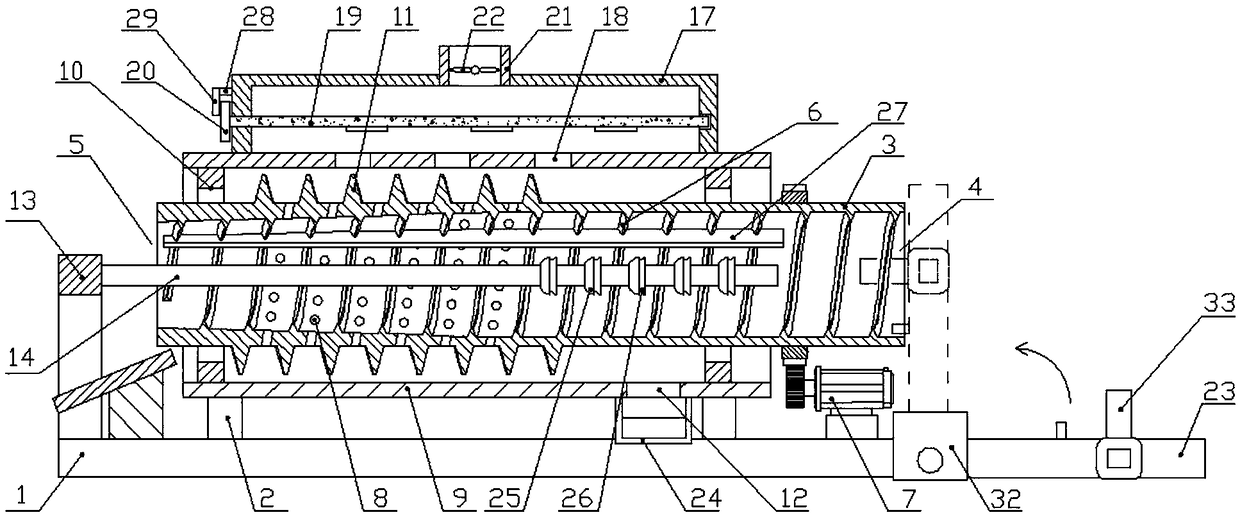

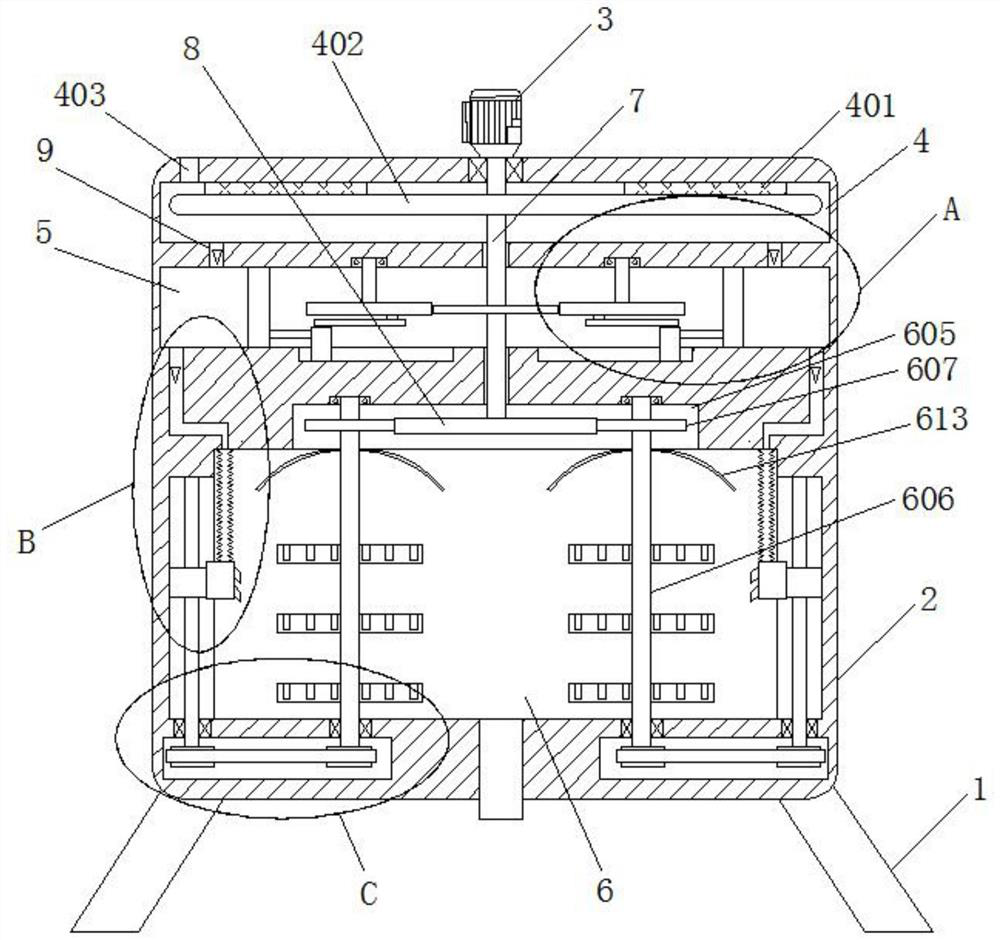

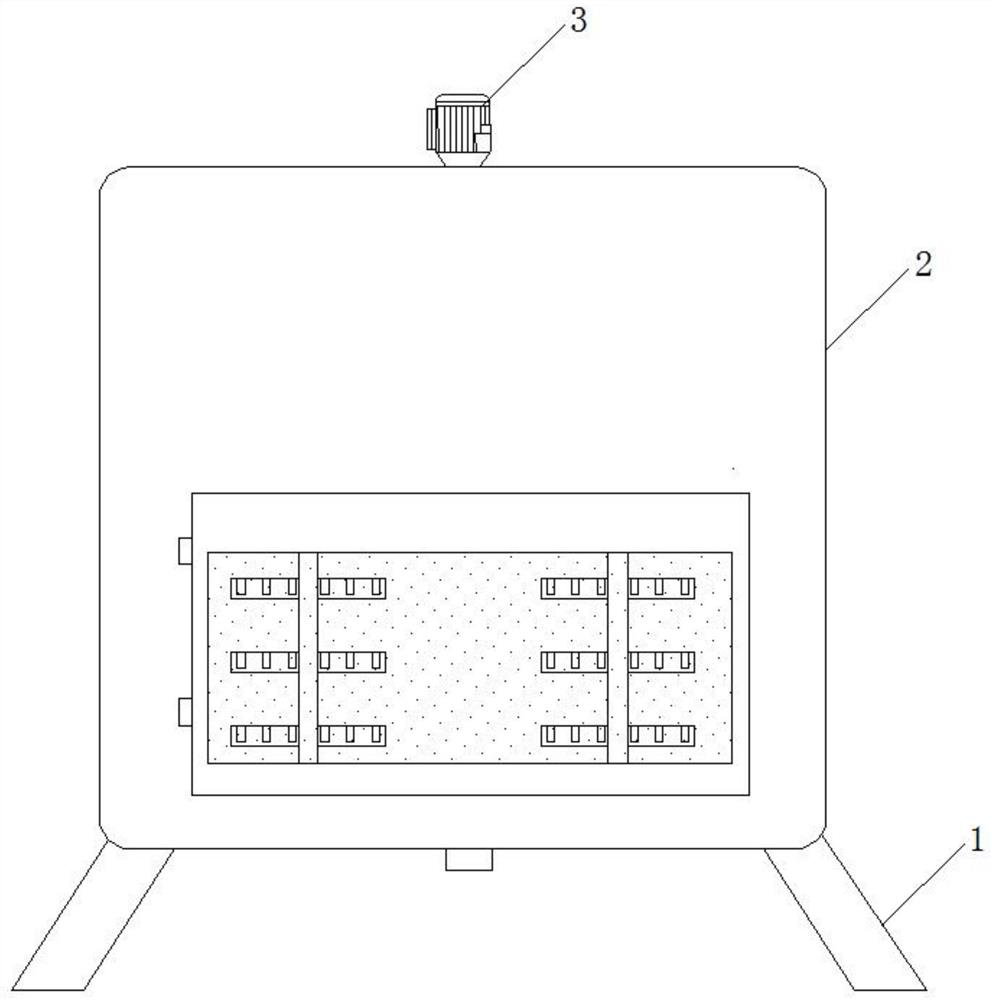

A sorting and drying mechanism for grain dryer

ActiveCN111721100BDry evenlyReduce resistanceDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The present invention relates to the technical field of grain dryers, and more specifically relates to a material distribution and drying mechanism for grain dryers, including a feed gate channel, a feeder and a drying tank, and the feeder includes a No. The motor, the central shaft and the dispersing disc, the drying trough includes sub-troughs, hot air blowers and slow-down units, with a ventilation net between the sub-troughs, the slow-down unit includes No. 2 motor, driving roller and driven roller, and the driven roller passes through the conveyor belt Connected with the driving roller, there are auxiliary rollers evenly distributed between the driving roller and the driven roller. The driving roller, auxiliary roller and driven roller are all fixedly connected with slow-down shafts, and the slow-down shafts are alternately distributed with positive arc grooves and inverted arcs Groove; the present invention thins the valley layer through each sub-groove, increases the ventilation area, prolongs the air path, makes the grain dry evenly, reduces the resistance of the hot air passing through the valley layer, cleans the grain up and down twice, and increases the cleaning of the dried grain Degree, by increasing the resistance and residence time, improve the efficiency of impurity removal and drying.

Owner:合肥麦稻之星机械有限公司

Massage chair

The invention provides a massage chair, and the chair comprises a seat plate, wherein a backup plate is arranged on one side of the seat plate, a containing groove is formed in the front side face ofthe backup plate, a plurality of transmission belts are arranged in the containing groove, beating protrusions are arranged on the transmission belts at equal intervals, a first elastic assembly is arranged on the front side of the containing groove, an air cavity is formed in the backup plate, and a circulation pipe is communicated between the air cavity and the containing groove; a plurality ofcirculation holes are formed in the front side face of the first elastic cushion, the ends of the circulation holes communicate with circulation air discs, the circulation holes communicate with the circulation pipes through first connecting pipes, the air cavity communicates with an air pump through a second connecting pipe, and the air pump is connected with a processor. People can be massaged conveniently, the transmission belts are started in a transmission mode to drive the beating protrusions on the transmission belts to move, the backs of the people can be massaged conveniently, the processor controls the air pump to frequently pump the air cavity, the air cavity keeps a certain negative pressure continuously, negative pressure air can blow the backs of the human bodies conveniently, and the comfort of people during massage is improved.

Owner:安徽钜将家具制造有限公司

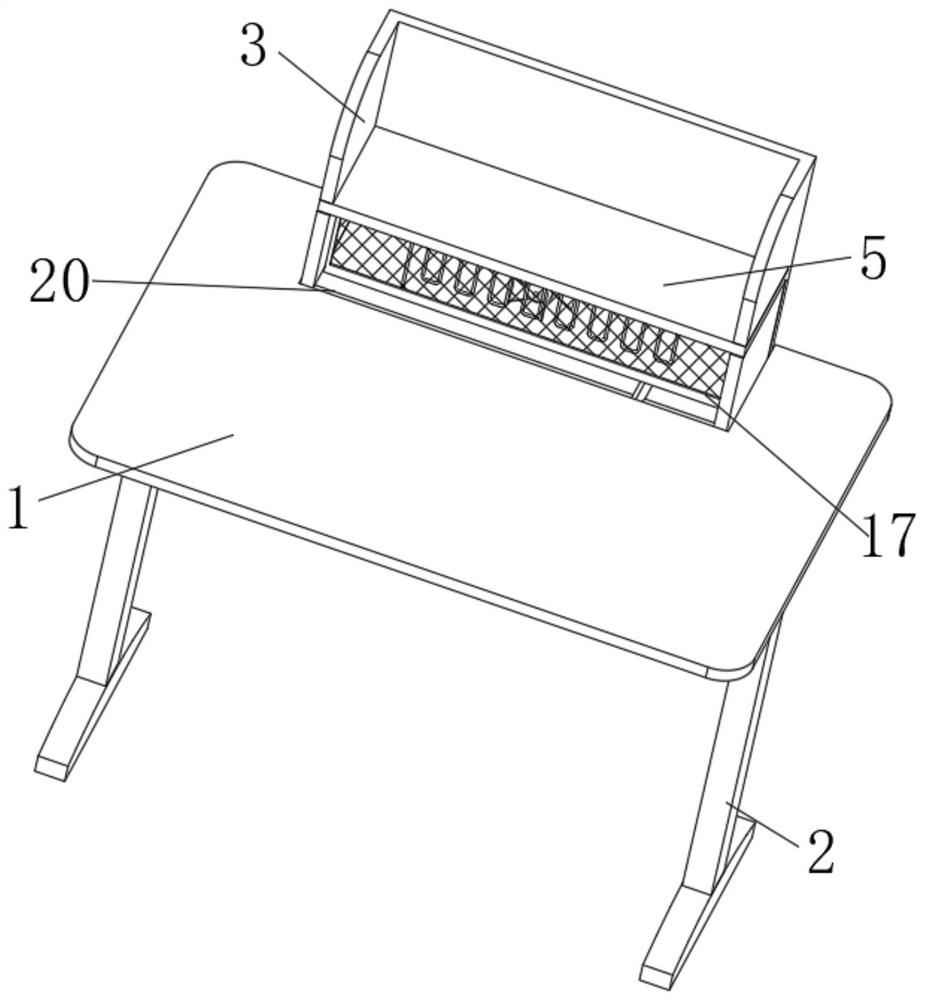

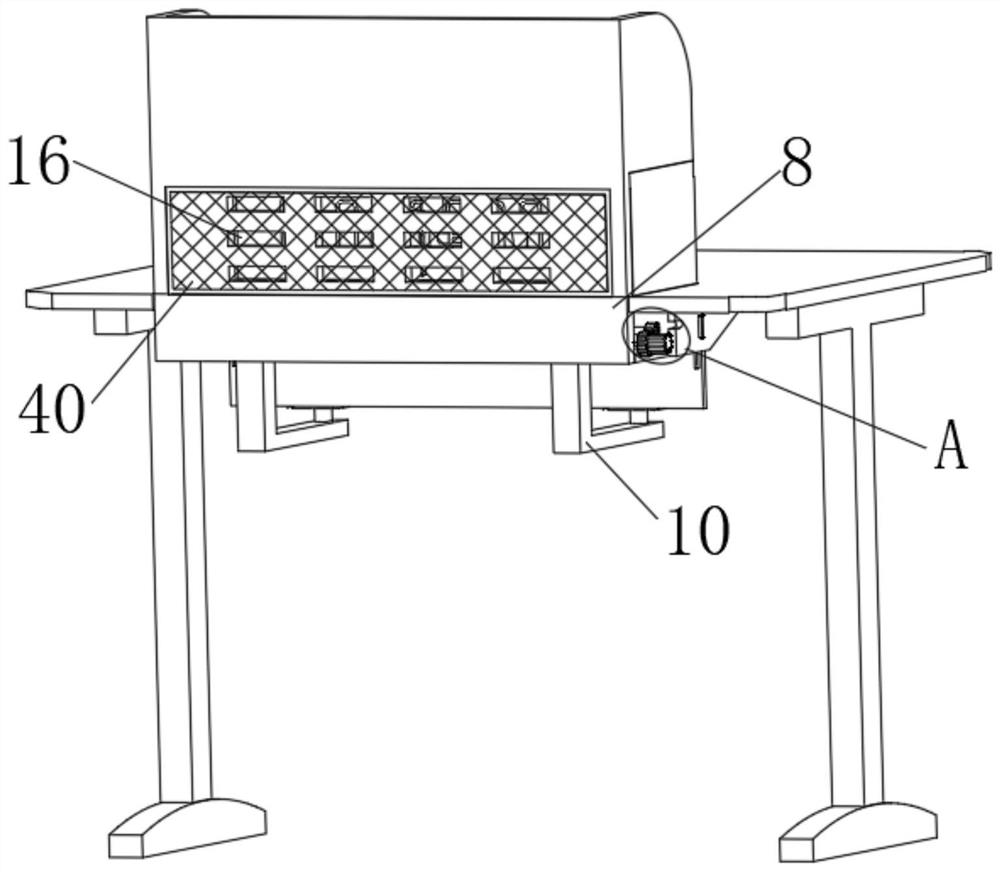

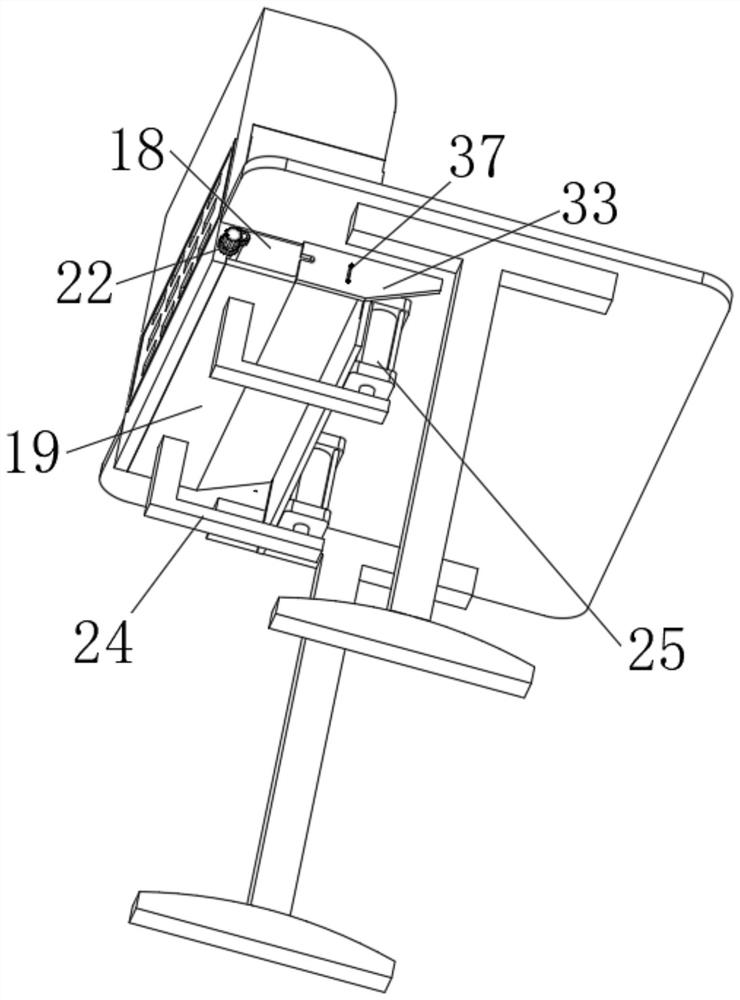

Intelligent desk

InactiveCN112293986AEasy to cleanAvoid getting dirtyHeating fuelCentral heating componentsDrive motorResistance wire

The invention discloses an intelligent desk. The intelligent desk comprises a desktop, desk legs are arranged at the bottom of the desktop, a bookshelf is arranged on the desktop, and a cleaning device facilitating rapid removal of eraser ash on the desktop is arranged on the desktop. Through the cleaning device, the eraser ash on the desktop is rapidly removed, and the eraser ash is avoided frompolluting the desktop and the hands and sleeves of a student; and fan blades are driven by a driving motor to rotate reversely, so that heat generated by an electrified resistance wire is convenientlyblown to the desktop in cold weather, and the situation that the hands of the student are frozen to be stiff and inconvenient to write is avoided.

Owner:ZHEJIANG BUSINESS TECH INST

Environment-friendly building material drying and spraying device with pre-cleaning function

InactiveCN112474160AWith pre-cleaning functionEasy to transportCleaning using toolsCleaning using gasesBuilding materialWood plank

The invention discloses an environment-friendly building material drying and spraying device with a pre-cleaning function, which comprises a box body, a conveying rod and a spraying liquid box; a fixing plate is fixedly connected to the left side of the middle of the box body; a hollow plate is fixedly connected to the left side of the fixing plate, and an air spraying pipe is fixedly connected tothe lower side of the middle of the hollow plate; a transfer box is connected to the rear side of the first sucking pump in an attached mode; the conveying rod is located on the inner side of the left end of the box body; a supporting plate is fixedly connected to the inner side of the upper left end of the box body; and liquid spraying pipes are welded to the left side and the right side of thehollow pipe. According to the environment-friendly building material drying and spraying device with the pre-cleaning function provided by the invention, an environment-friendly building material woodplate can be conveniently pre-cleaned, conveyed and turned over, spraying liquid can be conveniently and evenly sprayed on the wood plate, the spraying liquid can be conveniently stirred, redundant spraying liquid can be conveniently collected, peculiar smells can be conveniently purified, and operators can be in a good environment.

Owner:陕西中科文鼎信息科技有限公司

Plastic wardrobe with clothes dust removal effect

ActiveCN112263092AGuaranteed cleanlinessEasy to blow toWardrobesHousehold cleanersDust controlTorsion spring

The invention discloses a plastic wardrobe with a clothes dust removal effect, which comprises a wardrobe body, a wardrobe door is movably installed on the front face of the wardrobe body through hinges, an anti-torsion spring is fixedly connected to the back face of the wardrobe door, and the other end of the anti-torsion spring is fixedly connected with the right inner wall of the wardrobe body.According to the plastic wardrobe with the clothes dust removal effect, a wardrobe door is opened to enable the wardrobe door to swing anticlockwise through hinges, the wardrobe door pulls an anti-torsion spring in the swing process, the anti-torsion spring is stretched, meanwhile, the wardrobe door pulls a steel rope, the steel rope bypasses a pulley to pull a driving plate, the driving plate moves forwards, and the driving plate extrudes a piston through a telescopic rod; the piston slides forwards in the dust removal barrel, so that air in the dust removal barrel quickly flows and blows into the wardrobe body, residual fine dust on clothes in the wardrobe body can be removed, and when the wardrobe body is blown, the wardrobe door is in an open state, dust can be conveniently blown outof the wardrobe body, and dust prevention can be achieved at any time when the wardrobe is used; and cleanness of the wardrobe is kept.

Owner:合肥荣事达电子电器集团有限公司

A waste glass processing system

ActiveCN113385518BEasy to recycleEasy to removeSolid waste disposalGrain treatmentsNonferrous metalIron removal

Owner:莆田市日晶玻璃制品有限公司

An intelligent pathological slice processing system for gynecological tumors

ActiveCN113029723BEasy to holdEasy accessWithdrawing sample devicesPreparing sample for investigationGynecology departmentSurgery

The invention belongs to the technical field of medical devices and relates to the technical field of intelligent manufacturing. It specifically discloses an intelligent gynecological tumor pathological slice processing system, which includes a slice system and a control system matched with the slice system. The slice system includes a horizontally arranged base, a base A wax block moving device is arranged on the top of the wax block moving device, and a slicing knife matched with the wax block moving device is arranged above the wax block moving device; the wax block moving device includes a container, a clamping mechanism is arranged on the container, and a lifting mechanism is arranged below the container, and the lifting mechanism An advance and retreat mechanism is arranged below; the slicing knife is fixedly connected with the base; the invention provides an intelligent gynecological tumor pathological slicing processing system for automatic slicing and spreading.

Owner:HENAN CANCER HOSPITAL

High-voltage power transformation box with fixed clamping protection device

PendingCN114725801AEasy to installEasy to separateBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationElectrical and Electronics engineeringSupport plane

The invention relates to the technical field of power transformation boxes, and particularly discloses a high-voltage power transformation box with a fixing and clamping protection device, which comprises a power transformation box body, a fixing frame is fixedly mounted at the bottom of the inner side of the power transformation box body, a support frame is vertically mounted at the top of the fixing frame, and a frame seat is mounted at the front end of the support frame and close to the lower position; reinforcing bases are symmetrically installed at the bottom of the frame base, a mounting plate is installed on the inner side of the supporting frame, a U-shaped frame is fixedly connected to the position, close to the upper portion, of the front end of the mounting plate, one side edge of the U-shaped frame protrudes upwards, a rubber pad is installed at the bottom of the inner side of the U-shaped frame, and the inner sides of the two ends of the U-shaped frame are jointly connected with a U-shaped plate. The surface of the U-shaped plate is fixedly connected with a rubber seat, the top of the U-shaped frame is provided with a driving mechanism, electrical components and cables in a power transformation box can be rapidly clamped and fixed, the cables can be orderly separated, and later maintenance and distinguishing are facilitated.

Owner:BINZHOU POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com