Chemical fiber filament elasticity-improving process

A technology of chemical fiber yarn and process, which is applied in the field of chemical fiber yarn texturing technology, can solve the problems of not having the function of drying chemical fiber yarn, uneven oiling on the surface of chemical fiber yarn, and non-standard oiling of chemical fiber yarn, so as to avoid over The effect of uneven oil, easy use and cleaning, and structural improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

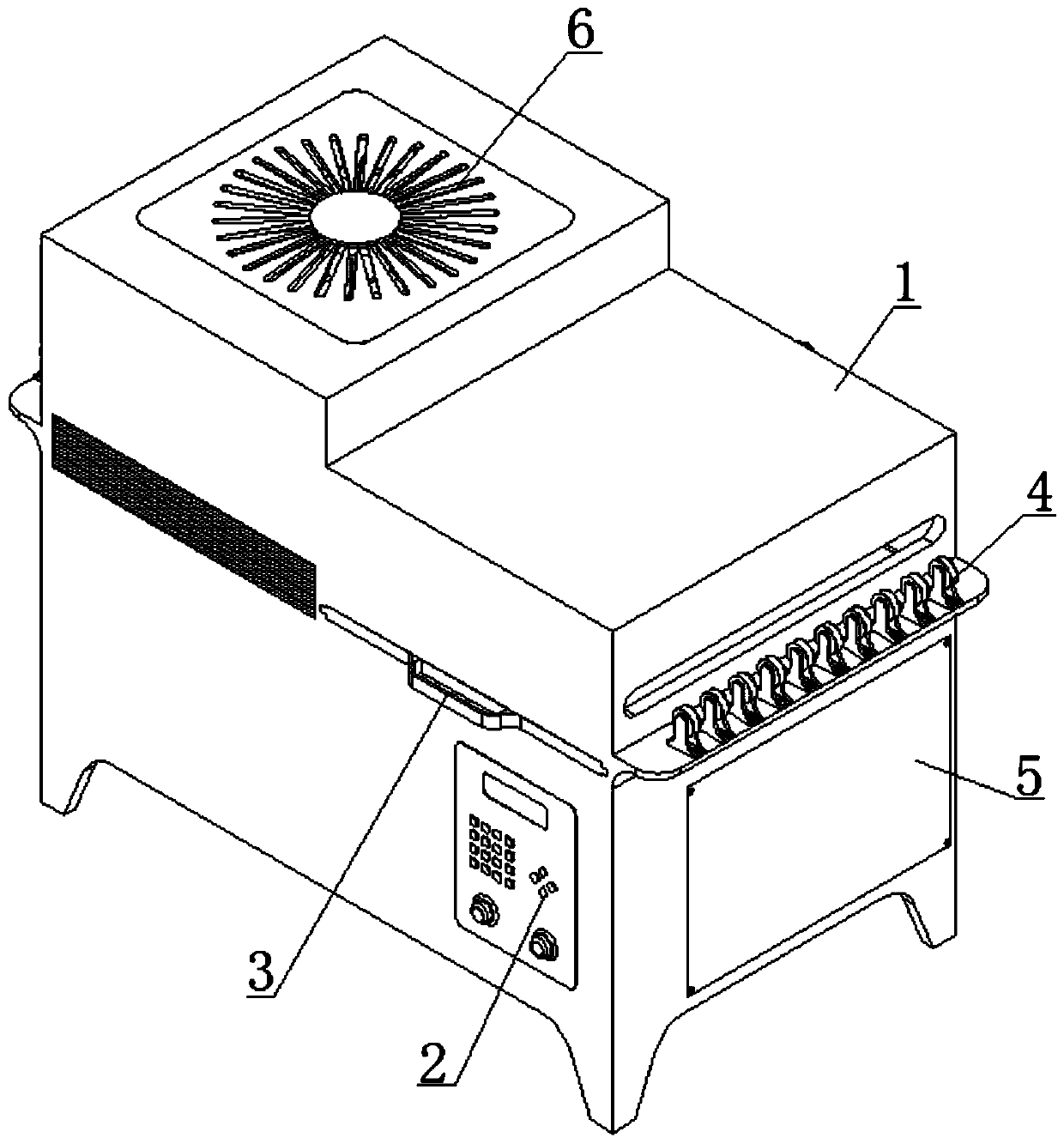

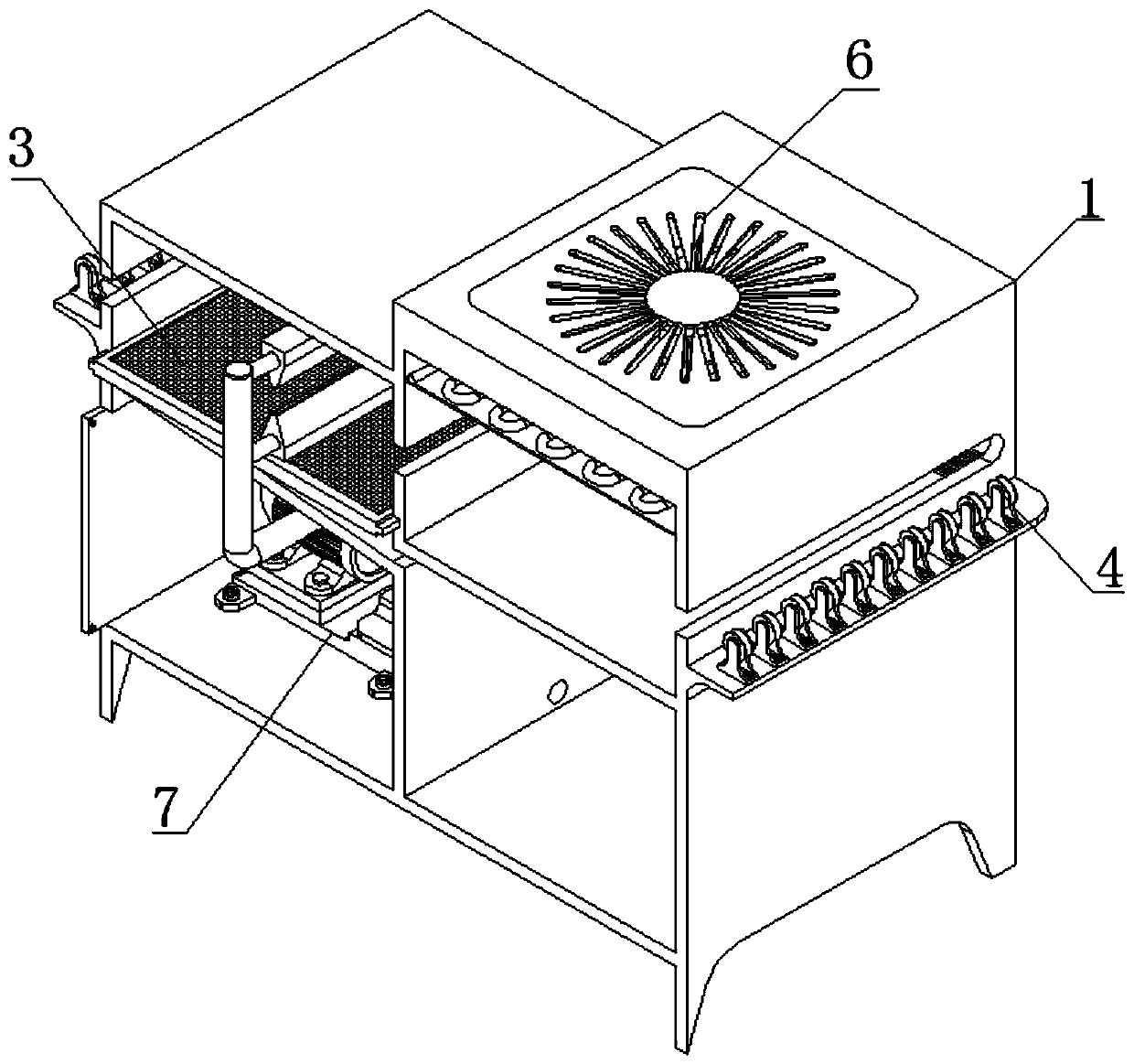

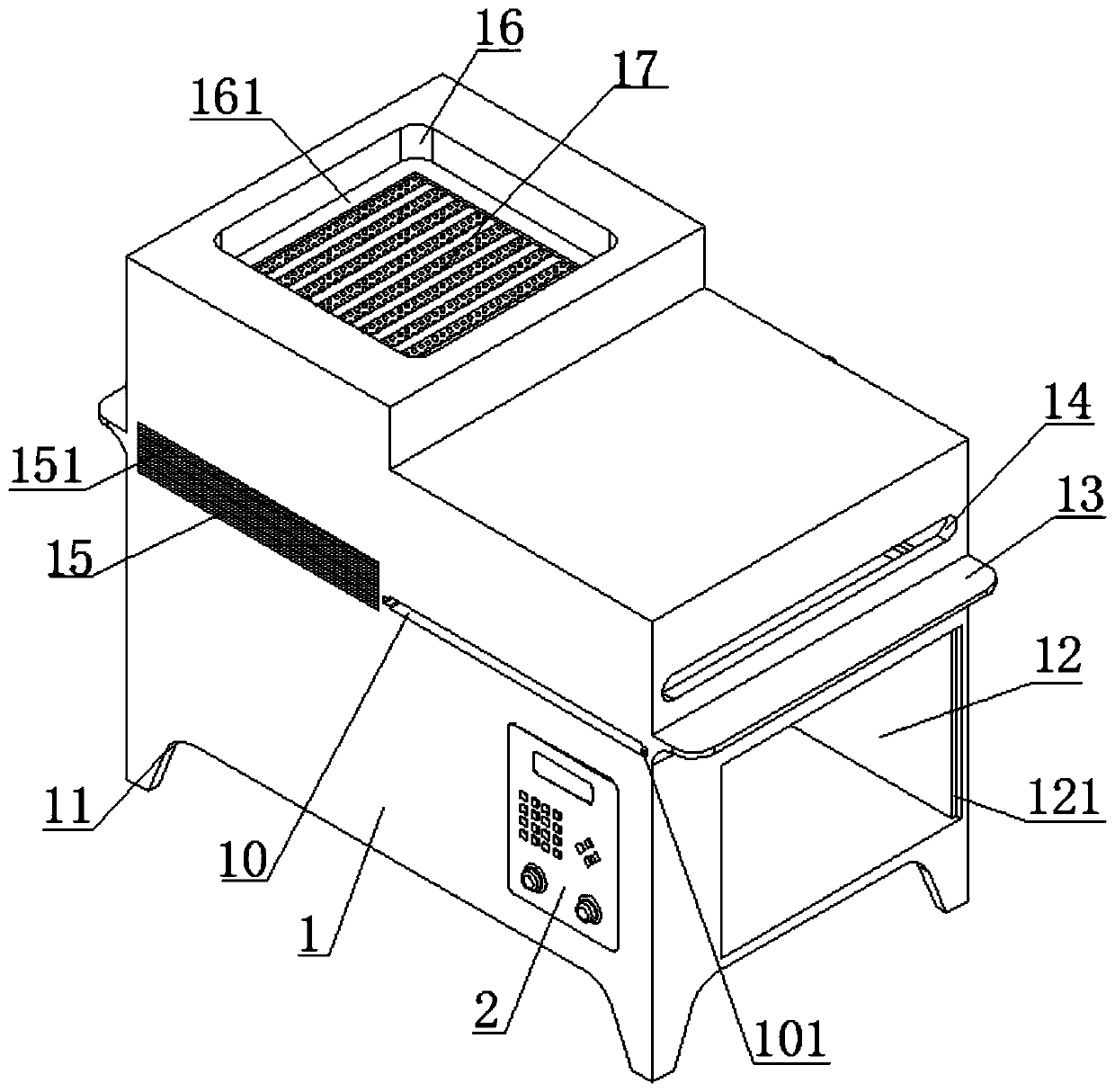

[0038] Example: refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown: a chemical fiber silk texturing process, the specific steps of the chemical fiber silk texturing process are as follows:

[0039] S1: Raw material feeding

[0040] Place the spun-formed chemical fiber on the pay-off device, and connect the chemical fiber to the texturing machine.

[0041] S2: Reloading machine

[0042] According to the desired elasticity of the chemical fiber, set the parameters on the texturing machine, and then start the texturing machine to texturize the chemical fiber.

[0043] S3: oiled

[0044] Pass the elasticized chemical fiber through the oiling equipment, oil the surface of the chemical fiber, and the oiling time of the chemical fiber shall not exceed one second, and make the surface of the chemical fiber dry after passing through the oiling equipment.

[0045] S4: Winding drum

[0046] After oiling and drying, the chemical fiber filaments are then put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com