Intelligent gynecological tumor pathological section treatment system

A pathological slice and processing system technology, applied in scientific instruments, sampling, measuring devices, etc., can solve the problems of unfavorable pathological analysis for doctors, lack of intelligence, automation, and hindrance to medical development, etc., and achieve the effect of stable automatic slicing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

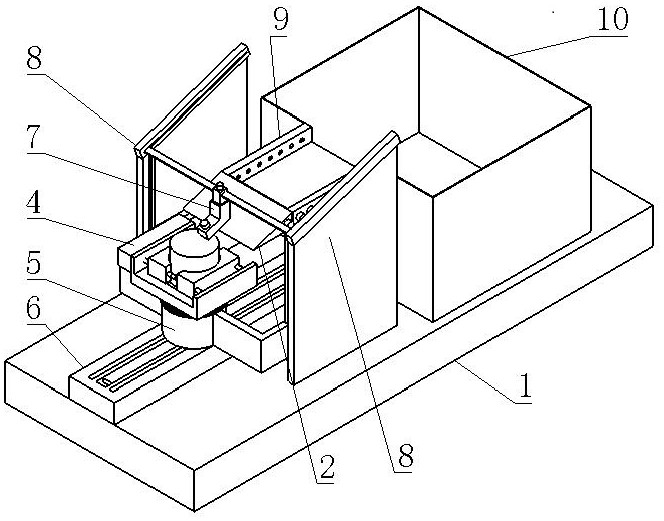

[0048] An intelligent pathological slice processing system for gynecological tumors, including a slice system and a control system cooperating with the slice system, such as figure 1 As shown, the slicing system includes a base 1 arranged horizontally, a wax block moving device is arranged on the base 1, and a slicing knife 2 matched with the wax block moving device is arranged above the wax block moving device; the wax block moving device includes a container 3, the container 3 is provided with a clamping mechanism 4, a lifting mechanism 5 is provided below the container 3, and a forward and backward mechanism 6 is provided below the lifting mechanism 5; the slicer 2 is fixedly connected with the base 1.

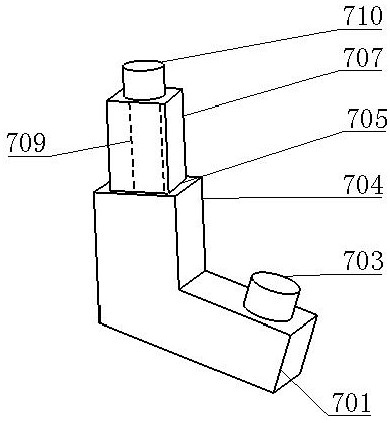

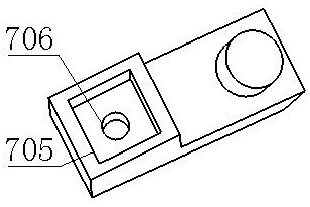

[0049] Such as figure 1 As shown, the slicing system also includes a slicing fixing device 7 matched with the wax block moving device, the slicing fixing device 7 is arranged above the wax block moving device, and the slicing fixing device 7 is connected with a synchronous ...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that no first blowing hole and second blowing hole are opened on the delivery pool 9 .

[0063] Such as Figure 19 , Figure 20 As shown, the top of the left and right side walls of the delivery pool 9 is provided with a blowpipe 905, and the blowpipe 905 includes a vertical section connected with the blower 902. The vertical section is connected with an inclined section, and the inclined section is backward, downward, and towards the delivery pool. 9 sloped in the middle. The working process of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the synchronous mobile devices are different.

[0066] Such as Figure 21 As shown, the synchronous moving device includes a first track, a slide bar and a first connecting plate arranged on the left side of the connecting block 707, and the first track, sliding bar and first connecting plate are not arranged on the right side of the connecting block 707. The synchronous moving device also includes a limiter 810. The limiter 810 includes limiting plates arranged on the left and right sides of the connecting block 707. The limiting plate fits with the left and right side walls of the connecting block 707 to limit the left and right shaking of the connecting block 707; The two connecting rods 811 are fixedly connected with the first track 802 . The working process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com