Energy-saving environmentally-friendly type paint spraying device for machining furniture

An energy-saving, environmentally friendly and furniture-friendly technology, which is applied in the direction of spraying devices, spray booths, and devices for coating liquid on surfaces, can solve problems such as the impact on the health of operators, strong pungent smell of paint, and low painting efficiency, so as to ensure safety, Improve environmental protection and reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

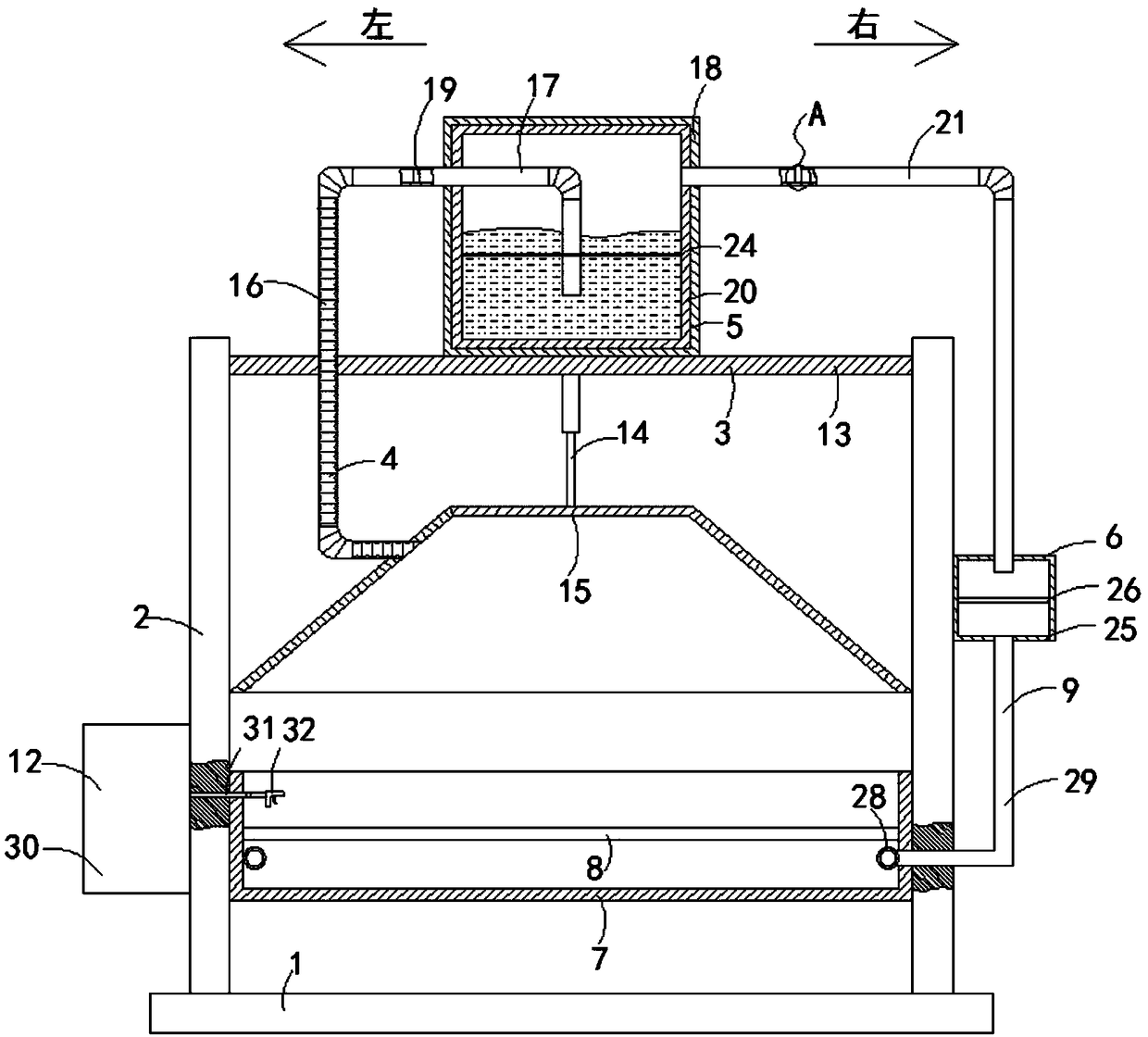

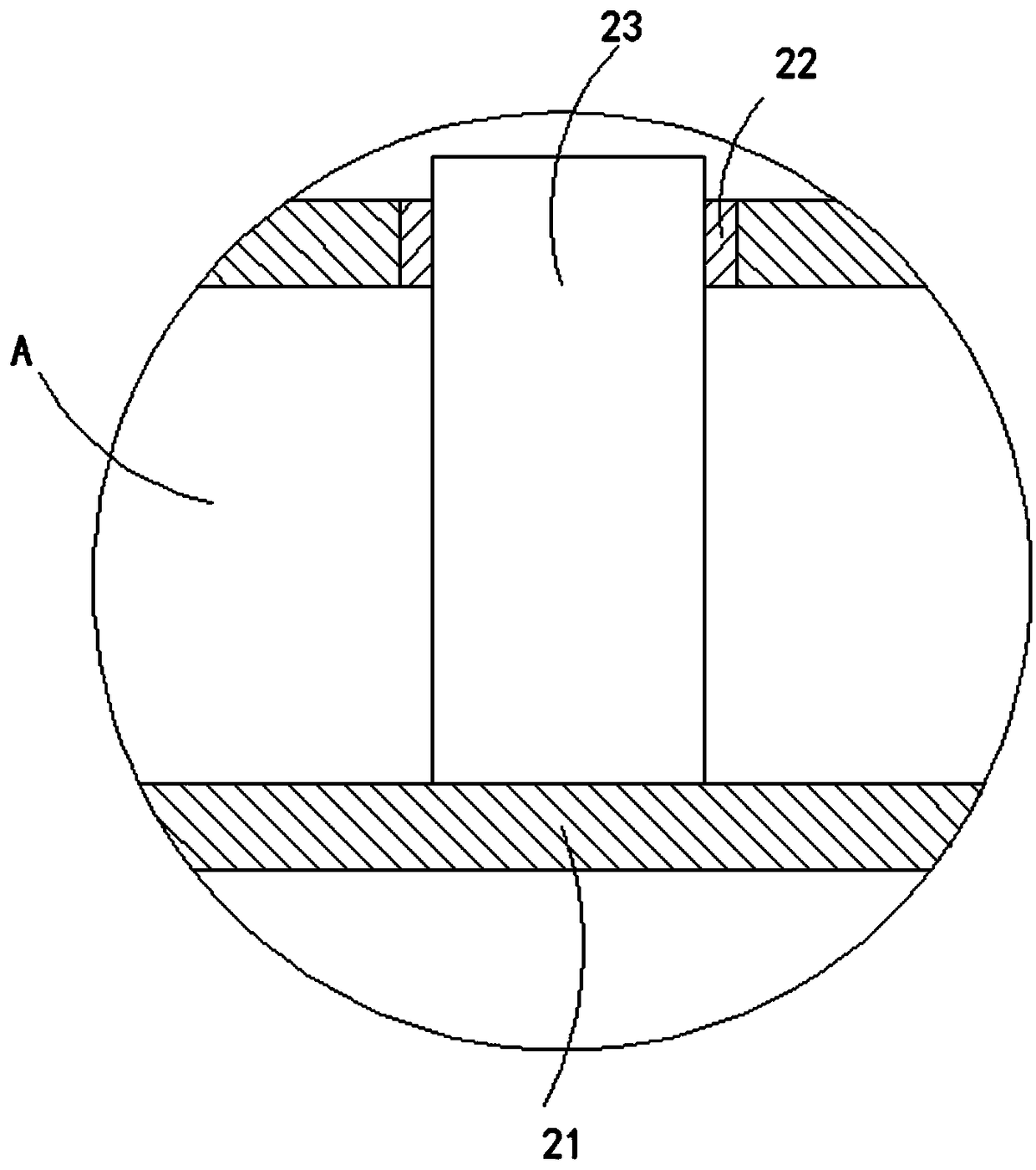

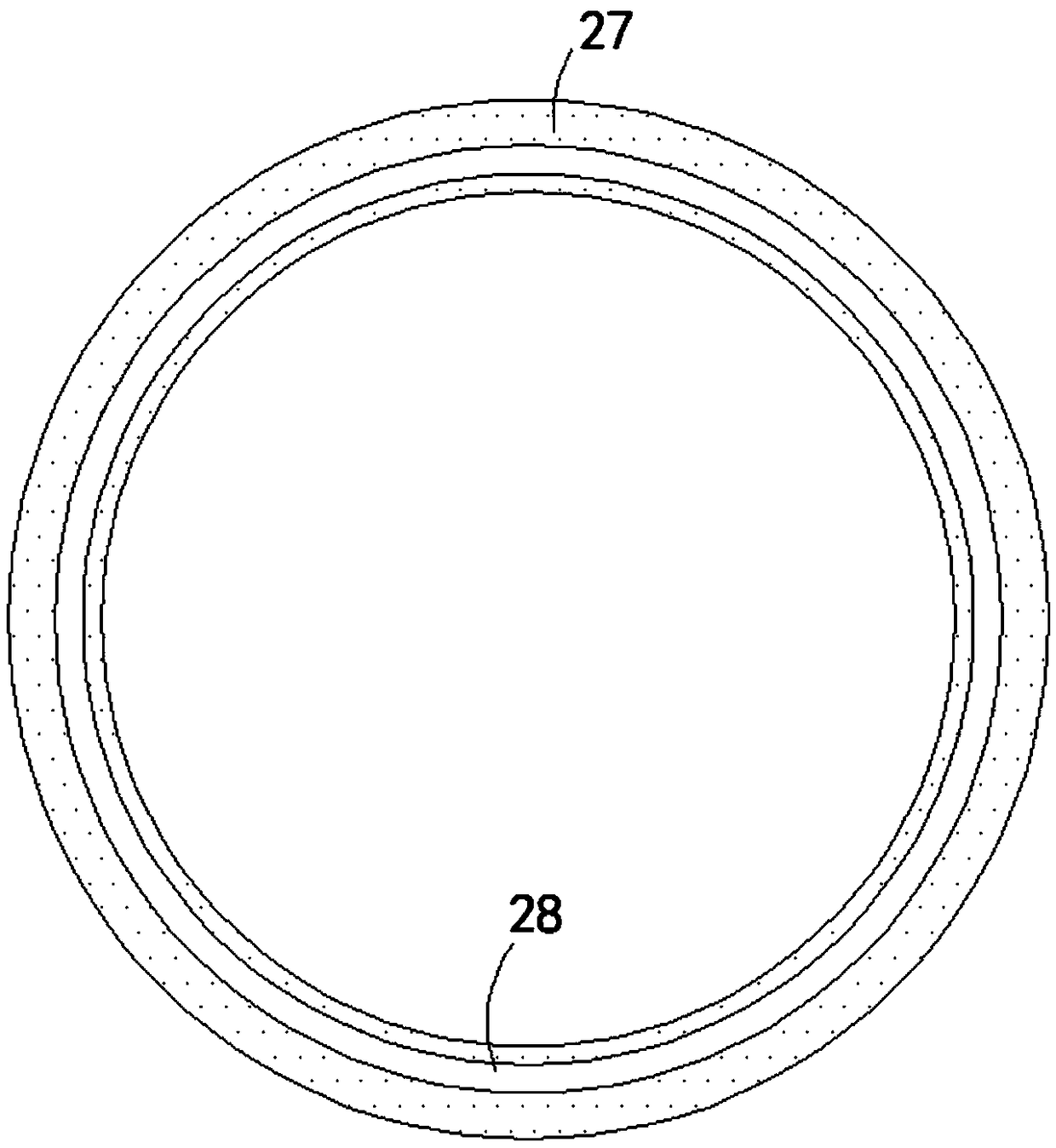

[0024] Such as Figure 1-4 As shown, an energy-saving and environment-friendly paint spraying device for furniture processing includes a base 1, two vertical plates 2 are fixedly connected to the upper end of the base 1, an air collection mechanism 3 is arranged between the two vertical plates 2, and the gas collection mechanism 3 The left and right ends are respectively fixedly connected with the side walls of the two vertical plates 2, the gas-collecting end of the gas-collecting mechanism 3 is communicated with and provided with a suction mechanism 4, and the upper end of the gas-collecting mechanism 3 is fixedly connected with an absorption mechanism 5, which is connected to the suction mechanism 5. The gas mechanism 4 is connected and arranged, and a heating mechanism 6 is fixedly connected to the side wall of the right vertical plate 2. It should be noted that the hot air flow generated by heating of the heating mechanism 6 cannot affect other components. The connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com