Cooling treatment device used for acid fracturing truck

A processing device, acid fracturing technology, applied in household refrigeration devices, fluid pressure actuation devices, engine cooling, etc., can solve the problems of inability to alternately change the position of fin plates, inconvenient use, slow cooling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

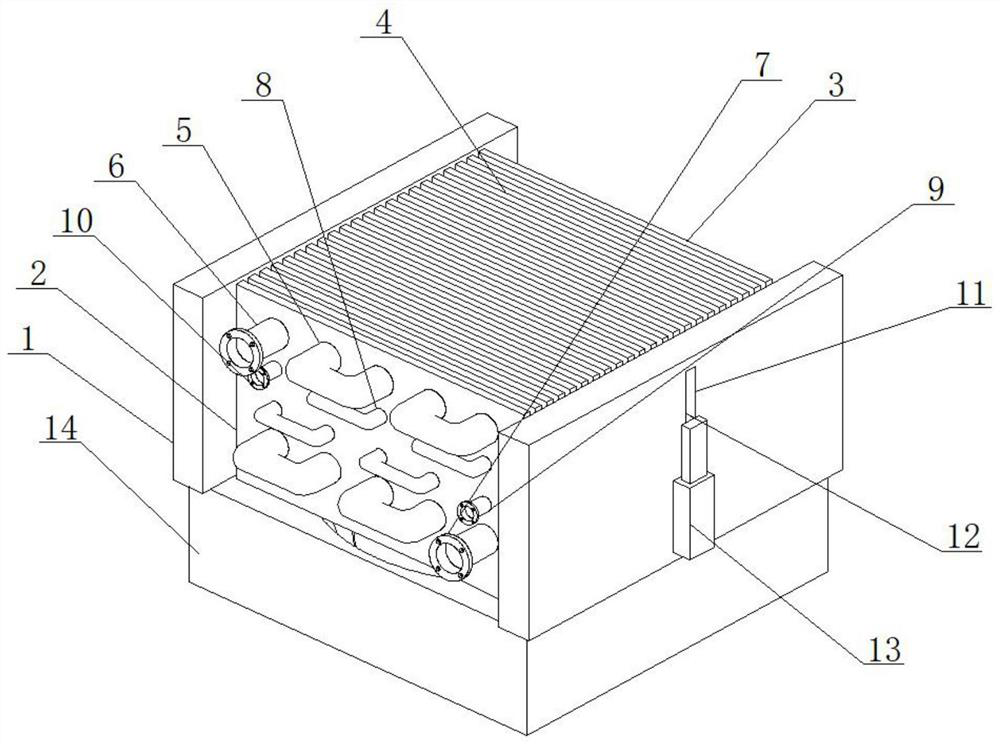

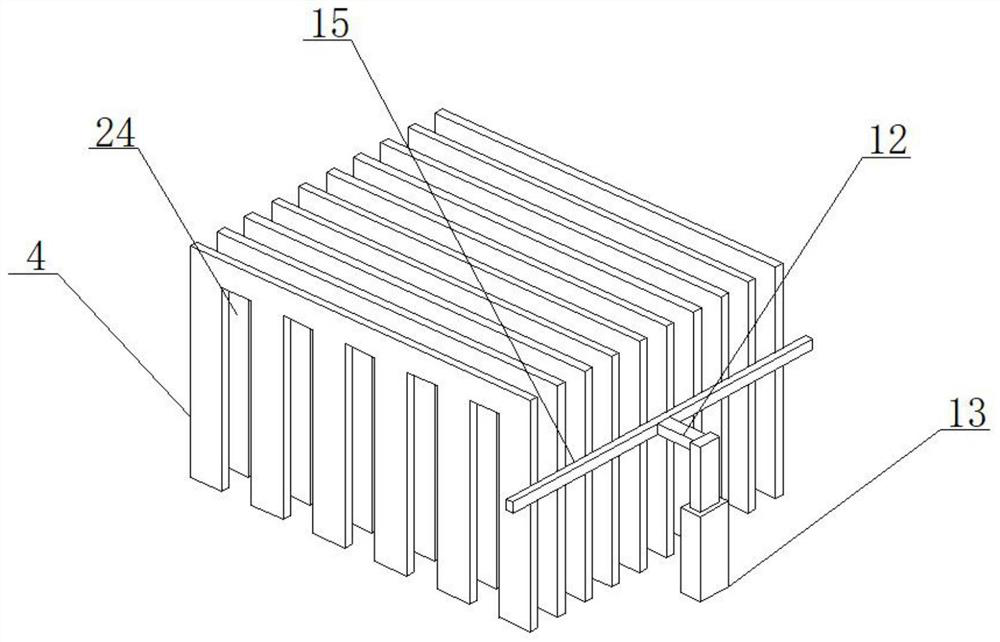

[0027] As a preferred embodiment of the present invention, the installation frame 17 is provided with an installation cavity 19, and a DC motor 20 is fixed inside the installation cavity 19, and a fan blade 21 is installed on the DC motor 20. The leaves 21 cooperate with the finned plate 4 .

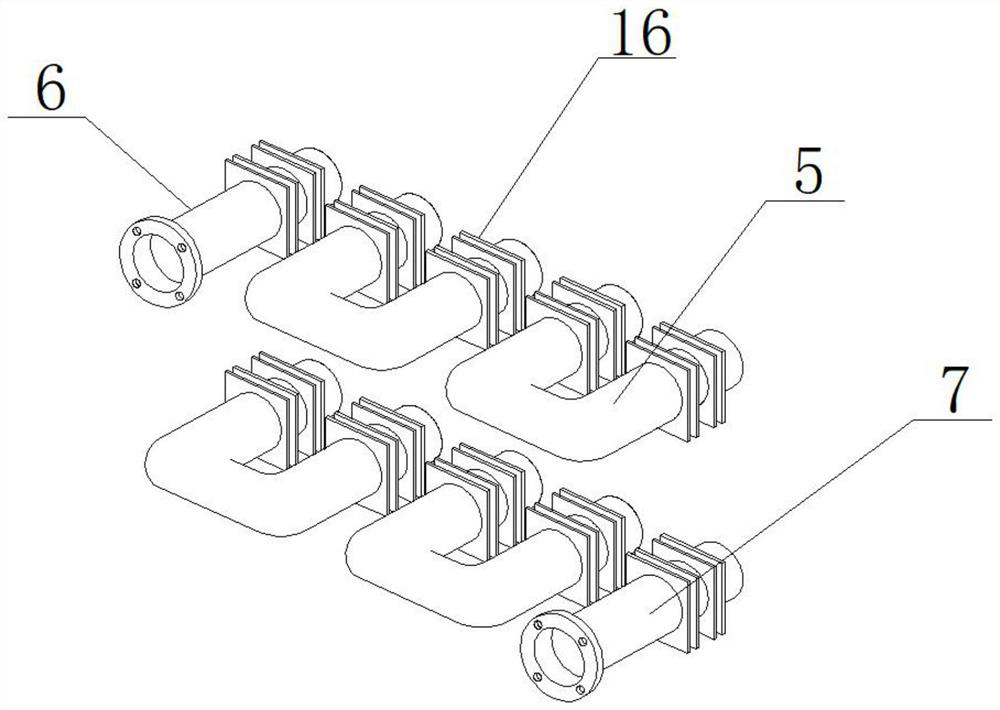

[0028] As a preferred embodiment of the present invention, a fixing ring is welded on the pipeline 5, a splint 16 is welded on the fixing ring, a fixing groove 24 is opened on the fin plate 4, and the fin plate 4 passes through The fixing groove 24 is installed between the clamping plates 16 .

[0029] As a preferred embodiment of the present invention, a metal plate 22 is welded on the cooling pipe 8 , the metal plate 22 is made of a heat-absorbing material, and one end of the metal plate 22 is matched with the pipe 5 .

[0030] As a preferred embodiment of the present invention, a fin plate 23 is installed between the fin plates 4, and a fixing groove 1 is opened on the fin plate 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com