Waste glass treatment system

A waste glass and processing system technology, applied in grain processing, solid waste removal, etc., can solve problems such as the impact of new glass products ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 of the present application discloses a waste glass processing system.

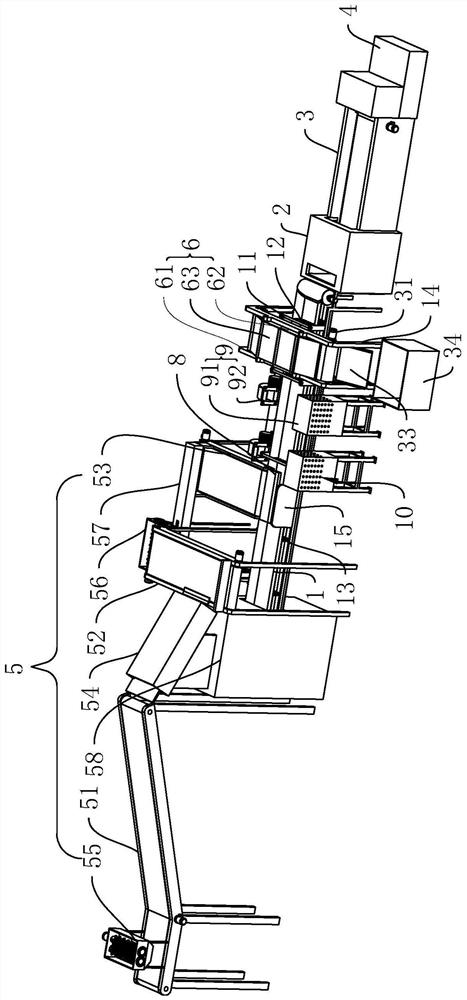

[0047] refer to figure 1 , a kind of waste glass processing system, from the upstream of the process to the downstream of the process, it includes a coarse crushing device 5, a first conveyor belt 1, a washing machine 2, a non-ferrous metal sorting machine 3 and a pulverizer 4; the coarse crushing device 5 includes a second A conveyor belt 51 , a third conveyor belt 52 , a fourth conveyor belt 53 , a screening machine 54 , a first coarse crusher 55 , a second coarse crusher 56 , a first cleaning machine 57 and a second cleaning machine 58 .

[0048] The first coarse crusher 55 is installed on the feed end of the second conveyor belt 51, and the discharge port of the first coarse crusher 55 faces the second conveyor belt 51, so that waste glass is directly discharged into the second conveyor belt after being put into the first coarse crusher 55. Conveyor belt 51. The sorting machine 54...

Embodiment 2

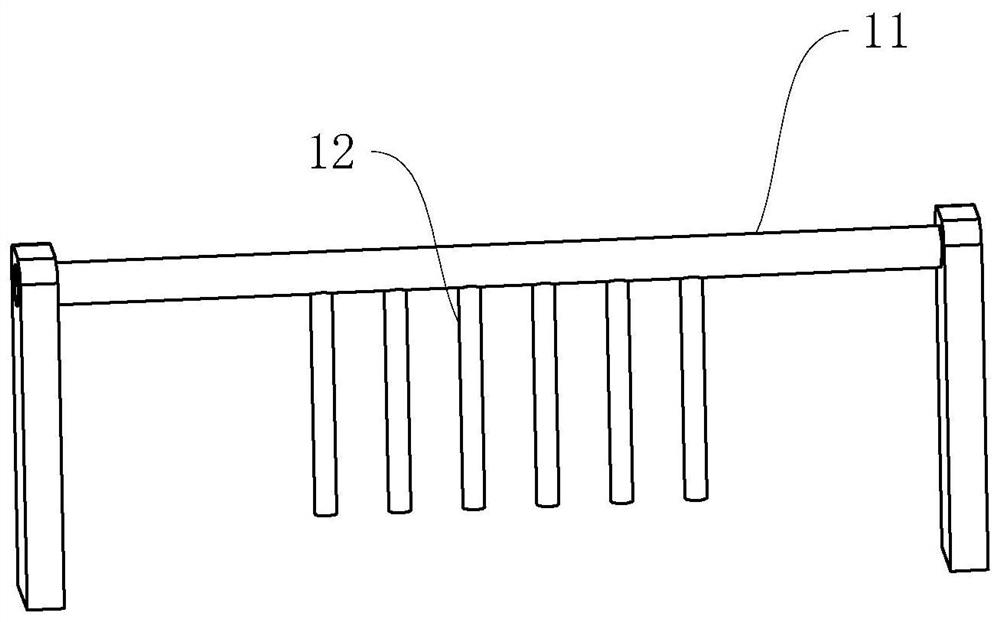

[0062] refer to Figure 5 , Image 6 , a waste glass processing system in Embodiment 2 of the present application, the difference from Embodiment 1 is that the diameter of the strut 12 gradually increases from one end close to the top of the frame 11 to the other end, so that two adjacent struts The distance between 12 gradually decreases from one end close to the top of the frame 11 to the other end. After the waste glass collides with the support rods 12, the waste glass closer to the bottom is less likely to pass between the adjacent two support rods 12, so that the waste glass will pile up and fall backwards, thereby increasing the impact of the support rod 12 on the waste and old glass. The stirring effect of the glass.

[0063]The top end of the strut 12 away from the frame 11 is connected with a slant bar 16, and the slant bar 16 is connected with a horizontal bar 17 parallel to the top surface of the first conveyor belt 1, and the middle part of the horizontal bar 17...

Embodiment 3

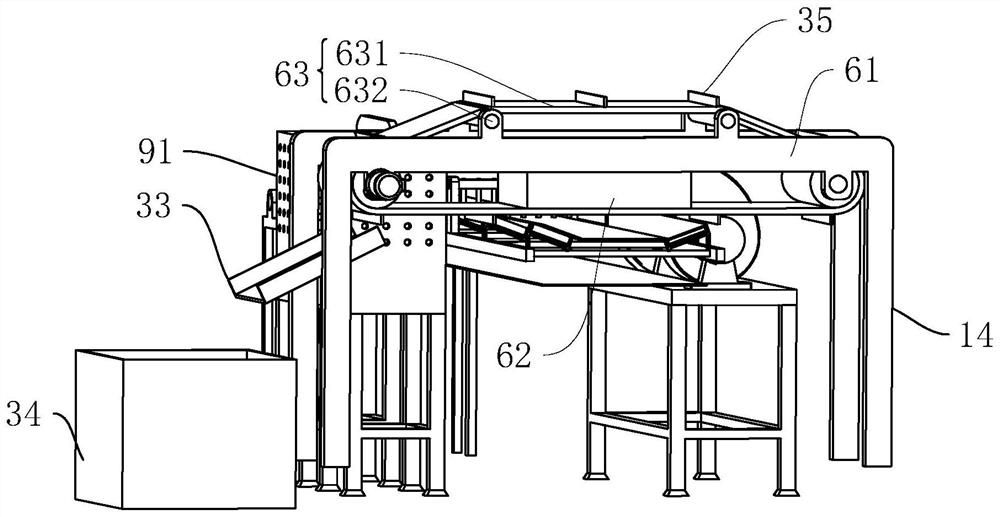

[0076] refer to figure 2 , Figure 10 , a kind of waste glass treatment system in the embodiment 3 of the present application, the difference with the embodiment 1 is that the end of the first conveyor belt 63 close to the collection box 34 is provided with a second conveyor belt 38 and a support frame 37, the second conveyor belt 38 It includes a belt body 381 , a third motor 382 , a second driving roller 383 and a driven roller 384 .

[0077] The second transmission roller 383 is erected above the collection box 34 through the support frame 37 , the third motor 382 is connected with the second transmission roller 383 , and the third motor 382 is used to drive the second transmission roller 383 to rotate. There are two driven rollers 384 , one driven roller 384 is rotatably connected to the fixed frame 61 , and the other driven roller 384 is rotatably connected to the support leg 14 .

[0078] refer to figure 2 , Figure 10 , the belt body 381 surrounds the second drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com