Quick clamping, walking and welding device capable of operating along annular track

A technology of circular track and welding device, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems that the equipment cannot meet the welding accuracy, clamping and efficiency, low efficiency, and high mechanism cost, saving manpower, running Smooth, high welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

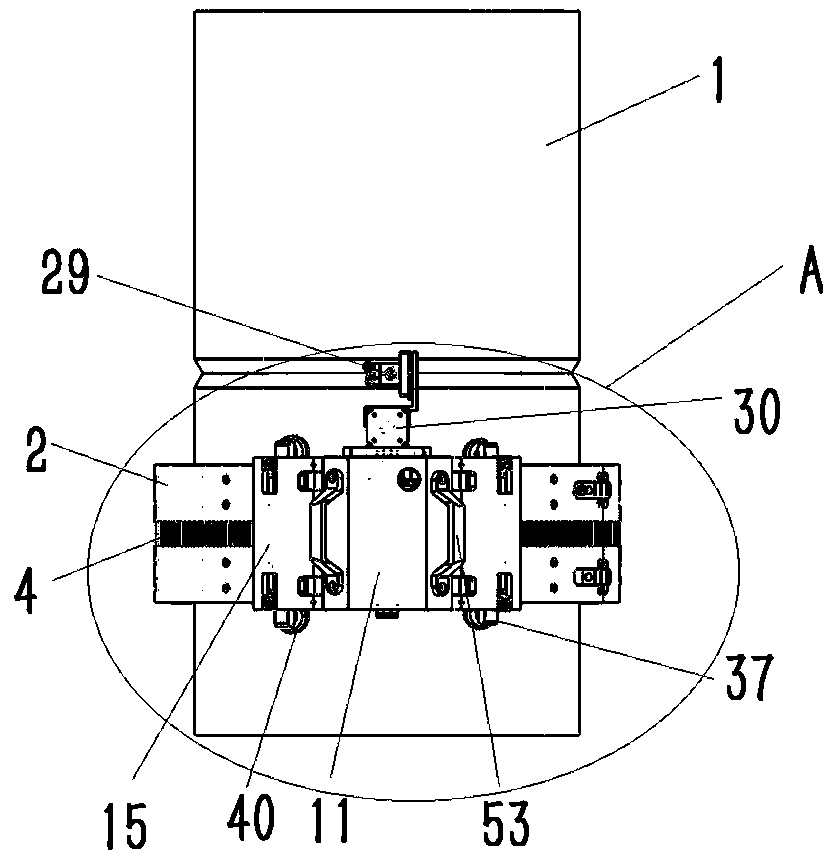

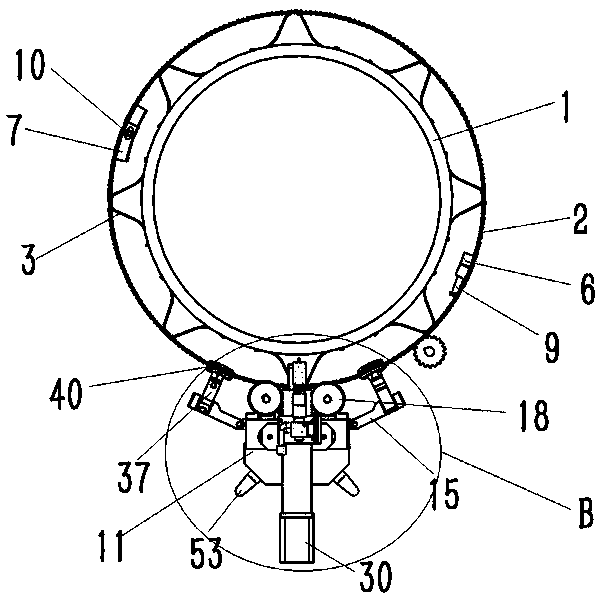

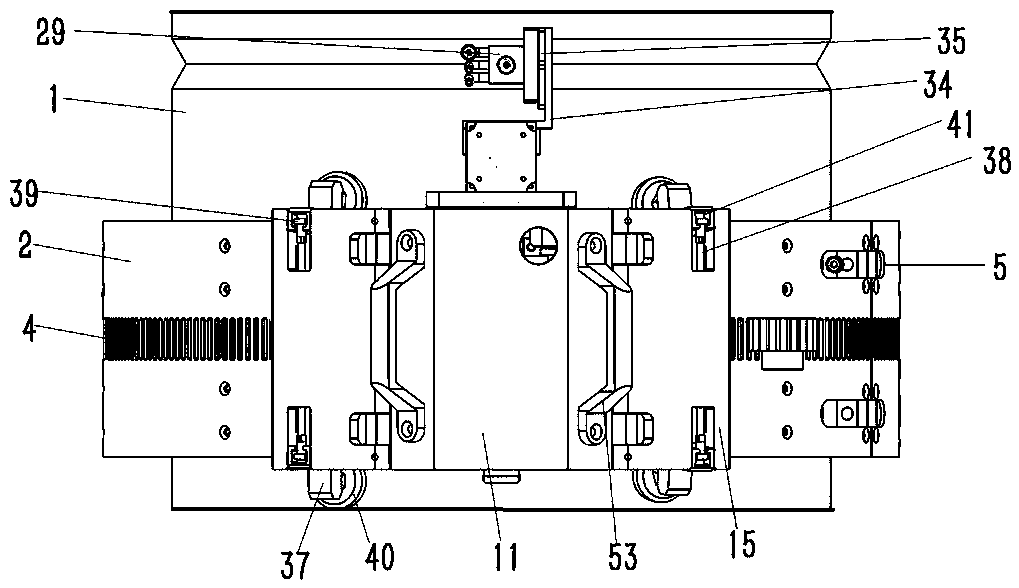

[0026] Such as Figure 1-Figure 11 As shown in the structure, a fast clamping, walking and welding device running along a circular track includes a clamping mechanism, a circular walking mechanism and a welding mechanism. The clamping mechanism includes two semicircular guide rails 2, two guide rails 2 The middle part of each guide rail is provided with several first strip-shaped through-holes 4 arranged along the vertical direction along the circumferential direction, and the middle part of the inner surface of the two guide rails 2 is provided with two rows of swallow-wing frames 3 up and down, and the two semicircular guide rails 2 start and end Linked to form a circular track, the upper and lower sides at the two ends of each guide rail 2 are provided with a first groove 5, and the first groove 5 at one end of the guide rail 2 is connected with a positioning block 6, and the positioning block 6 is provided with There is a first positioning hole, and the first groove 5 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com