Printer ink box automatic production method and system

A production system and printer technology, applied in printing, labeling machine, transportation and packaging, etc., can solve the problems of complicated carton unfolding action, inability to realize the gluing process, low action integrity, etc., to improve work efficiency and accuracy. , Folding is convenient and efficient, and stacking is more regular.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

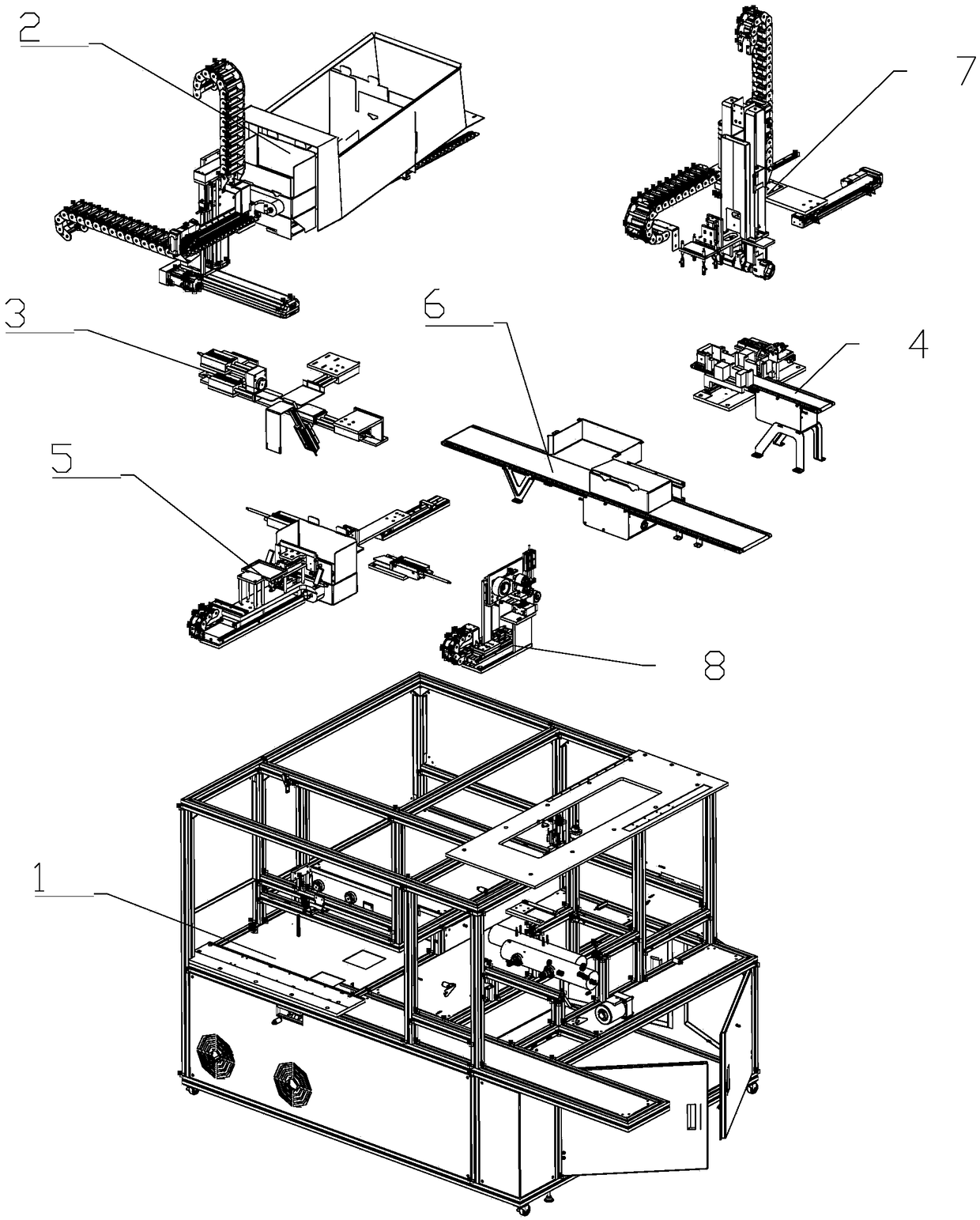

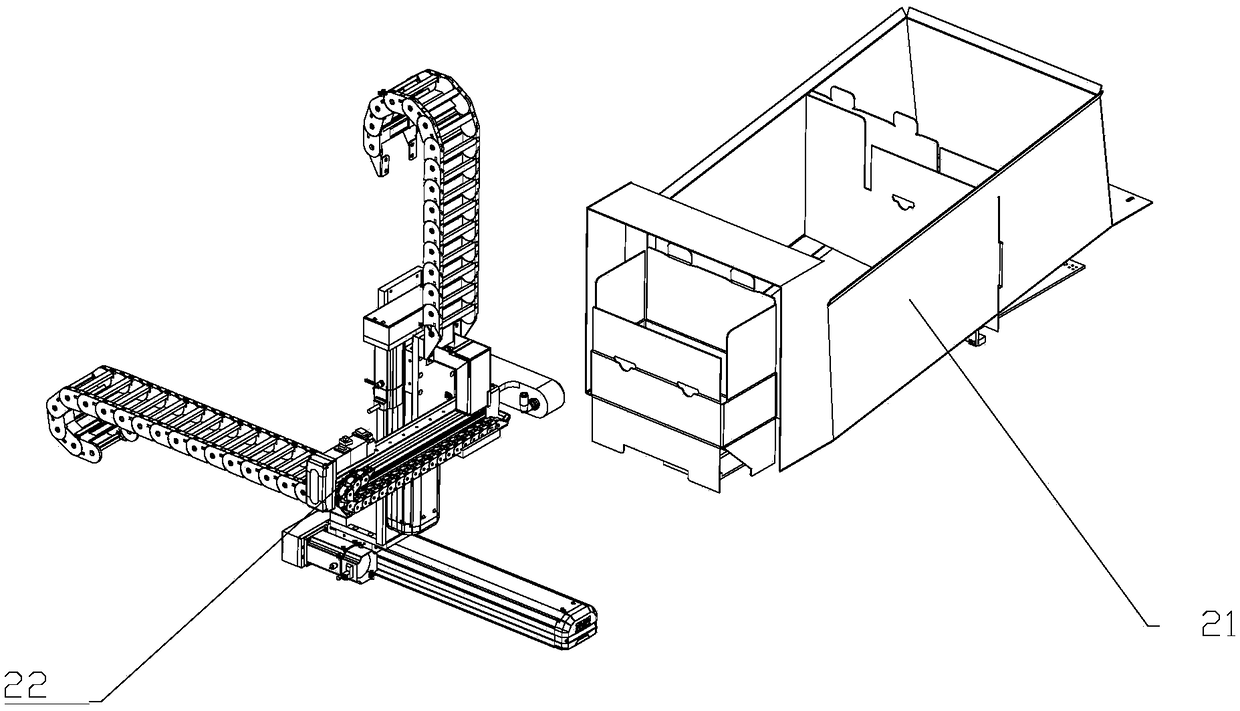

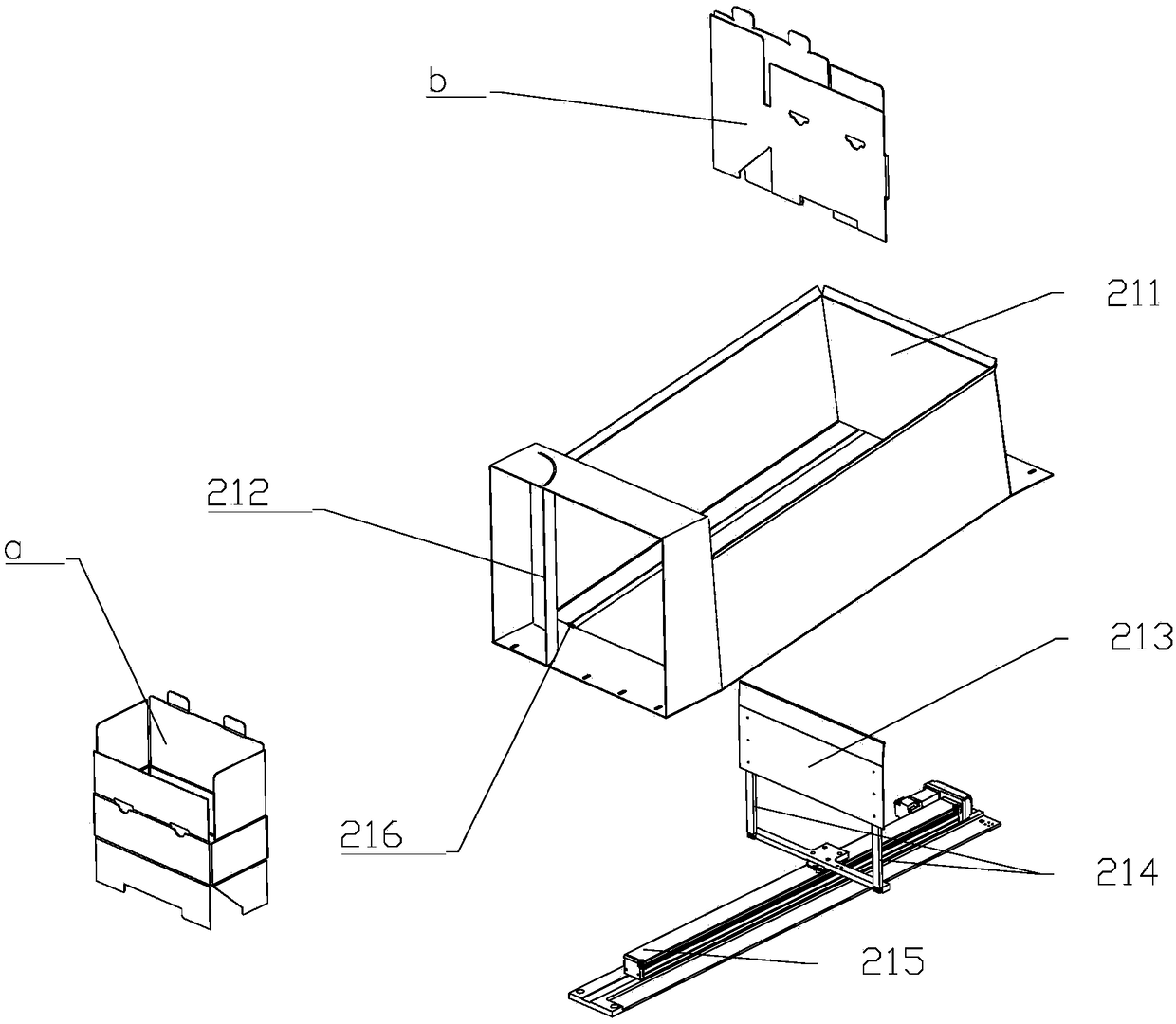

[0038] An automatic production system for printer ink cartridges, the production system includes production equipment and packaging equipment, such as figure 1 As shown, the packaging equipment includes a frame 1 and a carton drawing and forming device 2 installed thereon, a box bottom folding device 3, an ink cartridge feeding device 4, a box cover folding device 5, a packaging line 6, ink cartridges and manual handling Device 7 and labeling device 8 . The carton drawing and forming device 2 is used for storing folded cartons, and each time a carton is carried out by a manipulator to transform the plane into a three-dimensional shape. The box bottom folding device 3 is located at the side of the carton drawing and forming device 2, and is used to fold and seal the bottom surface of the carton that is carried out. The toner cartridge feeding device 4 is used for feeding toner cartridges to be packaged, and is located at the side of the packaging line 6 . The case cover foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com