Channel gate for hydraulic engineering and mounting method thereof

A technology for water conservancy projects and gates, which is applied in the field of channel gates and their installation in water conservancy projects, which can solve the problems affecting the normal operation of channel gates, the inability of channel gates to be unblocked, and the freezing and solidification of channel gates, so as to facilitate opening and closing and ensure The effect of verticality and overall structural design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

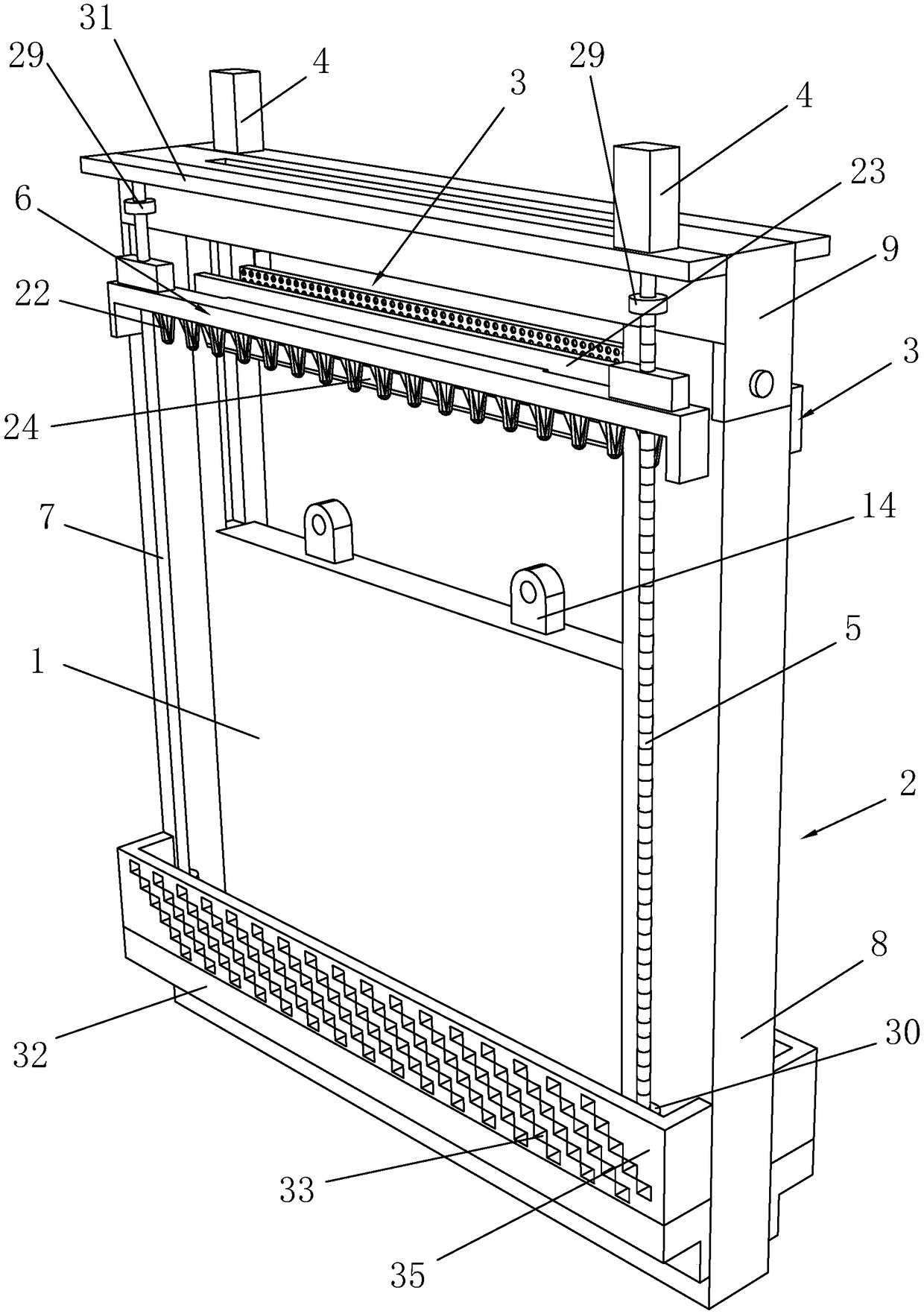

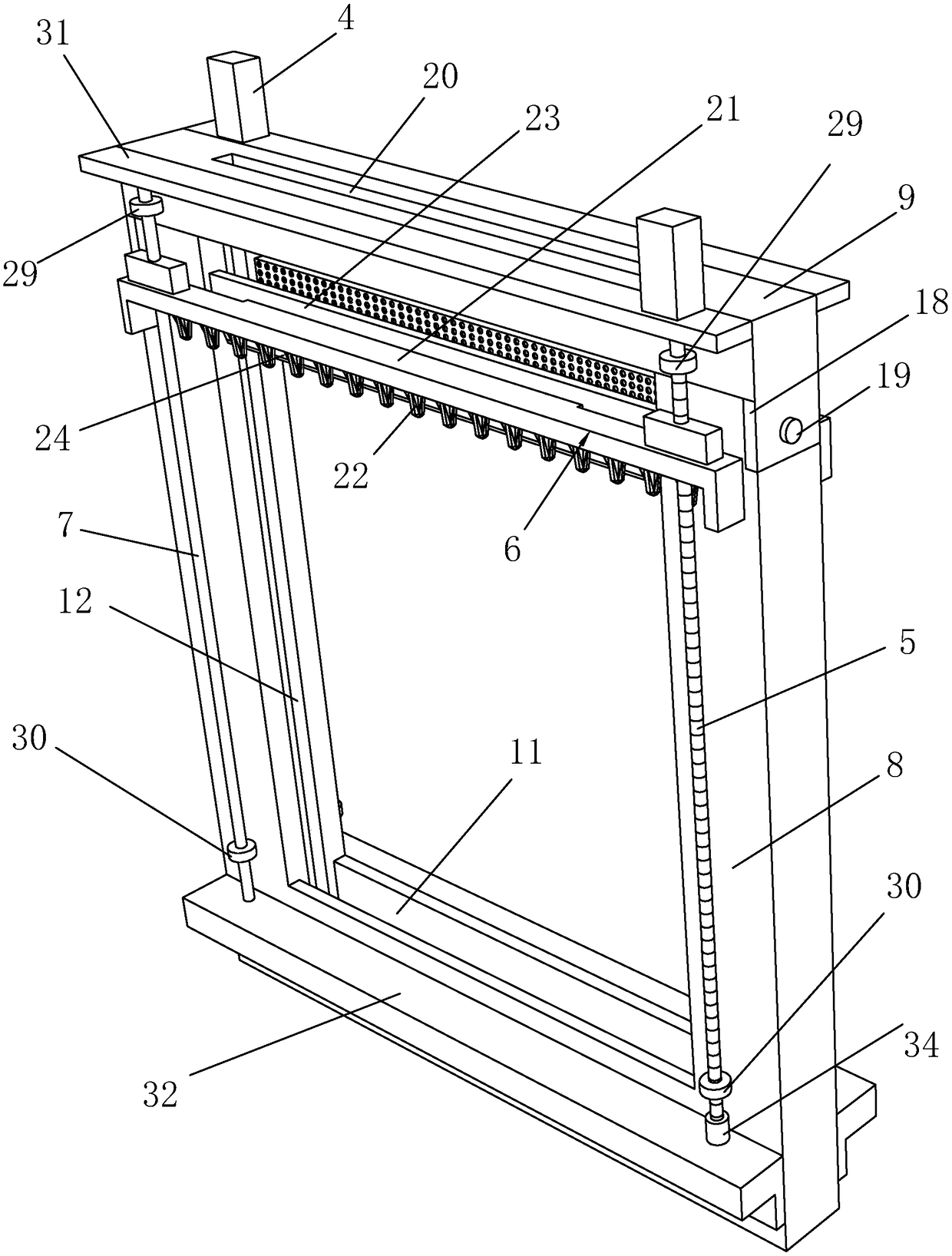

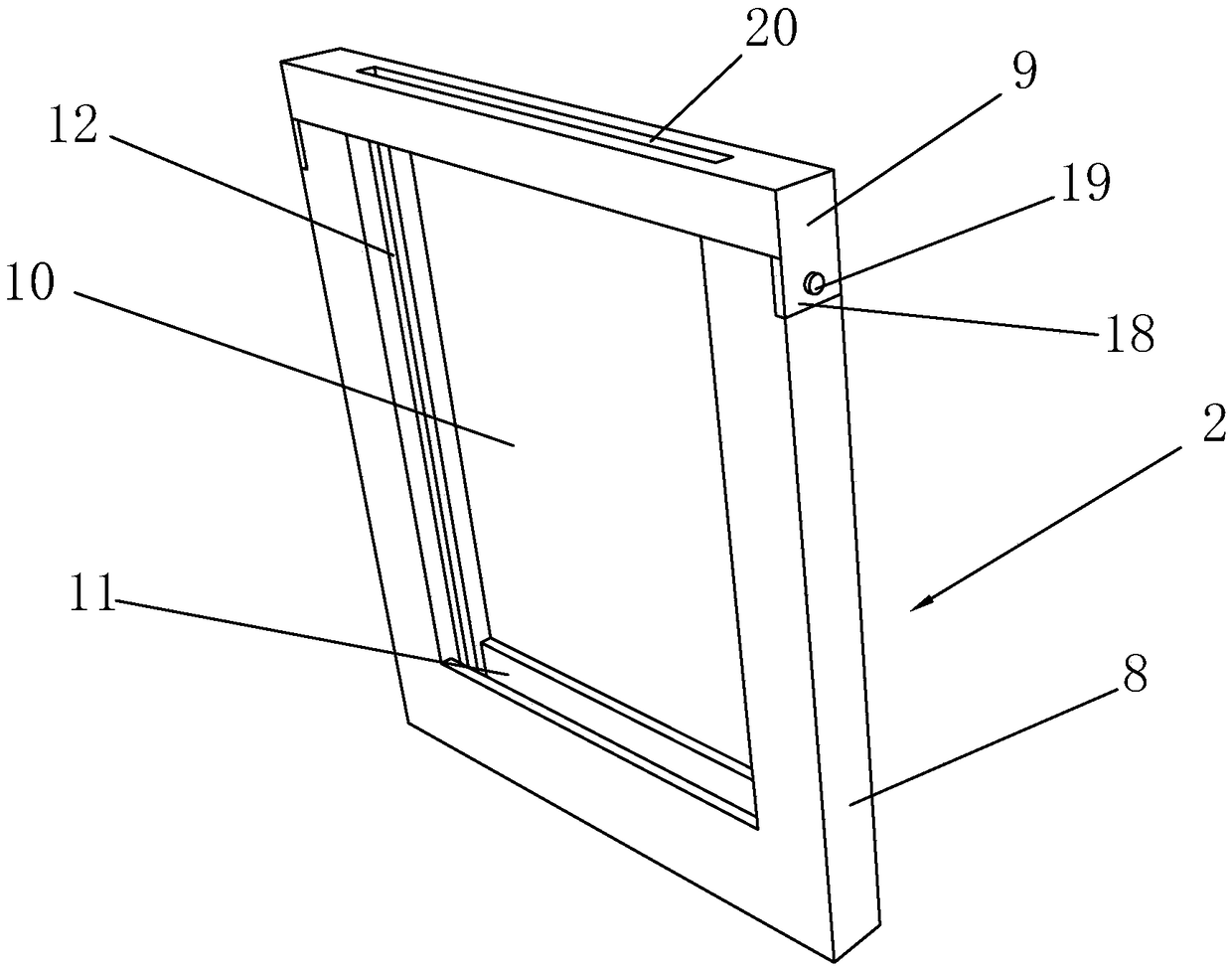

[0047] Such as Figure 1 to Figure 8 As shown, it is a channel gate for water conservancy projects according to the present invention, which includes a gate body 1 and a support seat 2. The gate body 1 is slidably connected in the support seat 2, and also includes two deicing devices 3, and the two deicing devices 3 correspond to Set on the front and rear sides of the support base 2, the two deicing devices 3 all include a driving motor 4, a rotating screw 5 and a deicing head 6, the driving motor 4 is located on the top surface of the supporting base 2, and the top of the rotating screw 5 is connected to the driving The motors 4 are connected, the rotating screw 5 is located on one side of the deicing head 6, the deicing head 6 is sleeved on the rotating screw 5, the other side of the deicing head 6 is provided with a balance slide bar 7, and the deicing head 6 is sleeved On the balance slide rod 7, the balance slide rod 7 and the rotating screw rod 5 are symmetrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com