Foundation pile torsional wave low strain detection method capable of eliminating bending and longitudinal interference

A detection method and torsional wave technology, applied in basic structure engineering, basic structure testing, construction, etc., can solve problems affecting the application and interference of torsional waves, achieve low vibration excitation requirements, accurate and reliable results, and improve accuracy The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

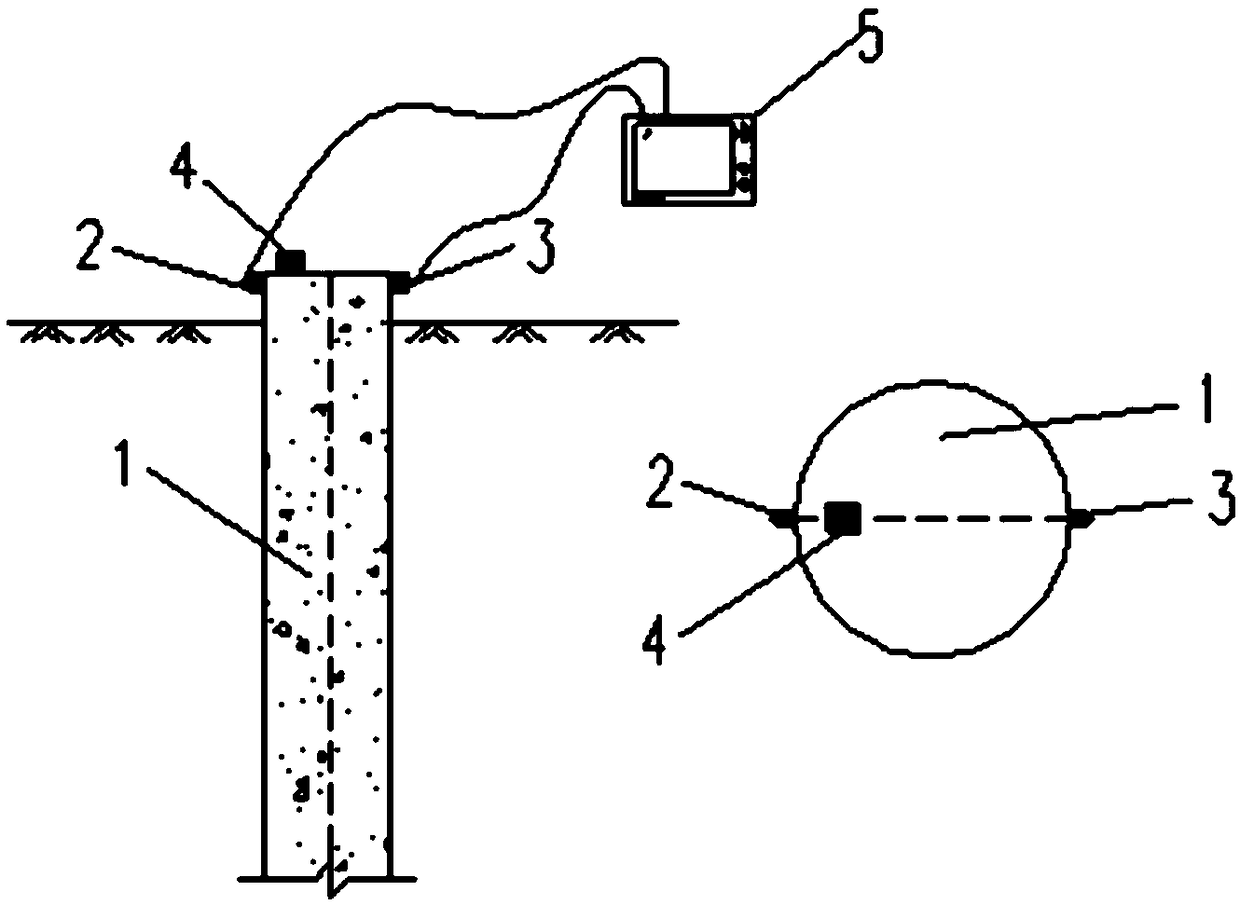

[0029] The invention provides a torsional wave low-strain detection method for foundation piles capable of eliminating bending and longitudinal interference. figure 1 A schematic diagram of the installation structure of the equipment used in this method is given, in which: the foundation pile 1, the first sensor 2, the second sensor 3, the excitation block 4, the dual-channel data acquisition instrument 5, the excitation block 4 can be installed on the pile The top or pile side, when installed on the top of the pile, it needs to be installed on the pile top plane close to the pile side, figure 1 What is given in is that the vibration block 4 is installed on the top of the pile and close to the side of the pile. The sensors can also be installed on the top of the pile or on the side of the pile. The two sensors should be symmetrical to the geometric center of the foundation pile. When the two sensors are installed on the top of the pile, they should also be installed on the pil...

Embodiment 2

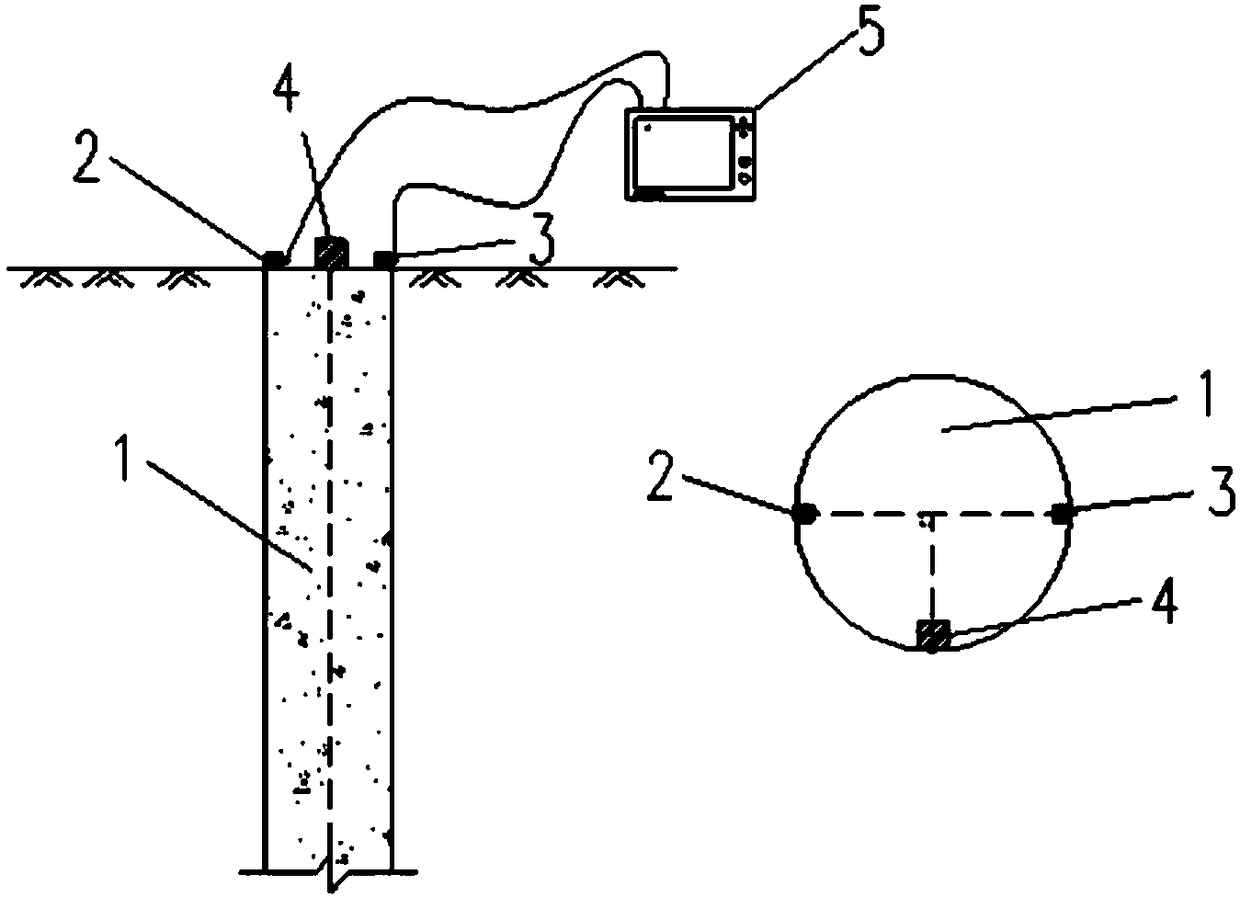

[0054] Due to the limited range and accuracy of the signal acquisition system, when the bending vibration is strong, in order to increase the proportion of the torsional wave signal and reduce the test error, it is sometimes necessary to set the angle between the sensor and the excitation block to 90°. figure 2 Another embodiment of the method is given, wherein: foundation pile 1, first sensor 2, second sensor 3, excitation block 4, dual-channel data acquisition instrument 5, excitation block 4 can be installed on the pile top or pile side, figure 2 What is given in is that the vibration block 4 is installed on the top of the pile and close to the side of the pile. The sensors can also be installed on the top of the pile or on the side of the pile. The two sensors should be symmetrical to the geometric center of the foundation pile. When the two sensors are installed on the top of the pile, they should also be installed on the pile top plane close to the pile side. figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com