Bidirectional resonating drilling speed increasing tool

A tool and drilling technology, applied in the field of two-way resonance drilling speed-up tools, can solve the problems of inability to directly act on the PDC bit, inability to reduce the large friction near the bit, and no installation, and achieve simple structure, increased rigidity, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

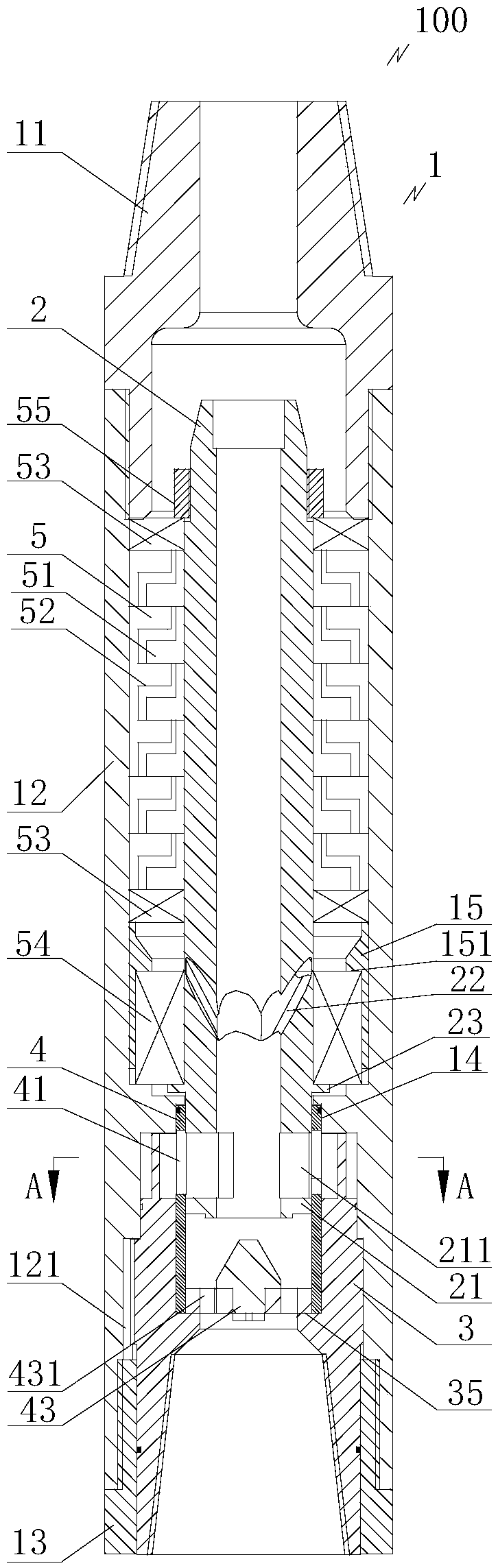

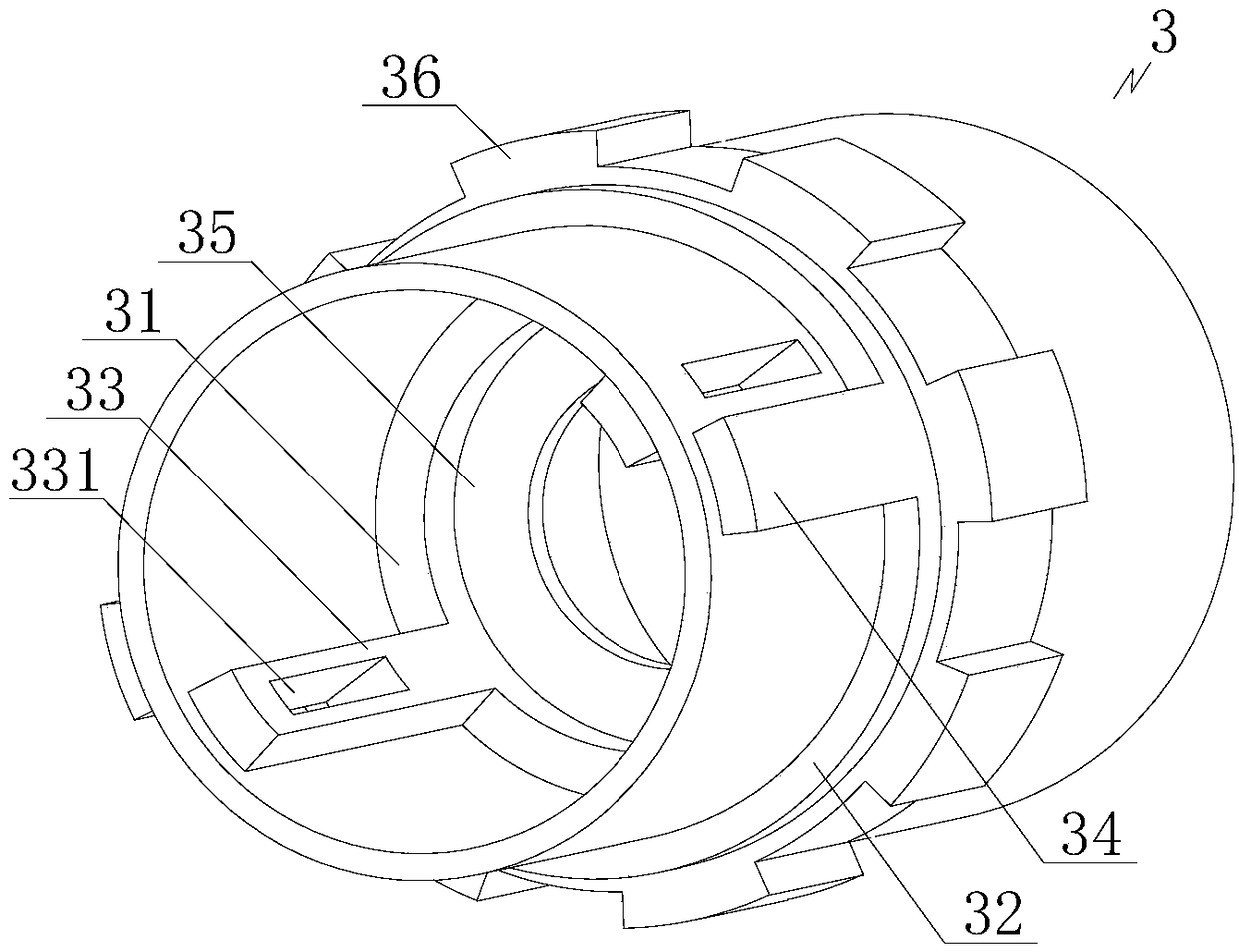

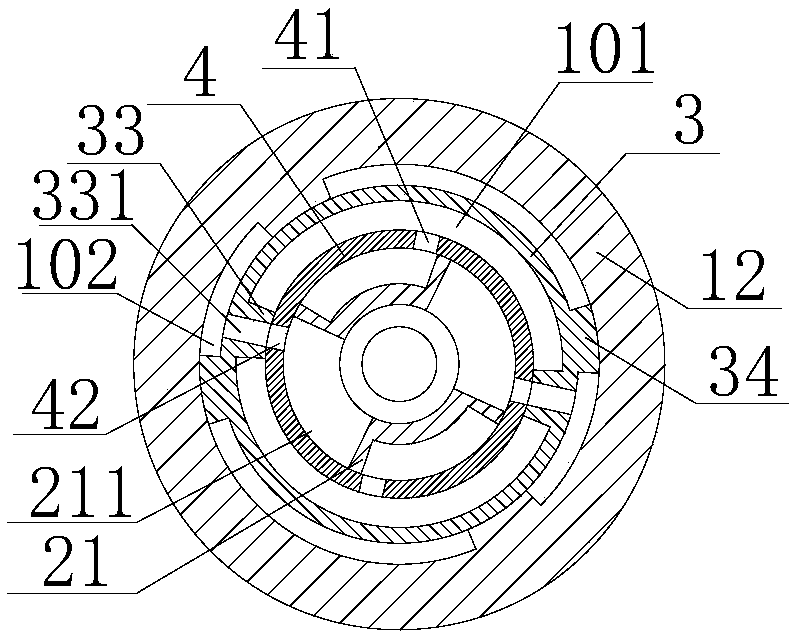

[0045] Figure 1 to Figure 4As shown, the present invention provides a two-way resonant drilling speed-increasing tool 100, which includes a hollow tool shell 1, and the top of the tool shell 1 is connected to a downhole power tool or a drill collar; To the rotating hollow drive shaft 2, a hollow drill seat 3 that can swing circumferentially and can slide axially is set below the drive shaft 2, and the bottom of the drill seat 3 connects the drill bit (the prior art, not shown in the figure), The lower portion of the side wall of the drive shaft 2 is circumferentially spaced and radially symmetrically provided with first outer fan-shaped protrusions 21, the outer walls of each first outer fan-shaped protrusions 21 can be in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com