Shield tunnel segment joint sealing gasket with concave and convex cross section forms

A shield tunnel segment and gasket technology, which is used in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of waterproof failure of segment joints, small contact stress on contact surfaces, and separation of gaskets and sealing grooves. The effect of increasing long-term water resistance, preventing separation and falling off, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

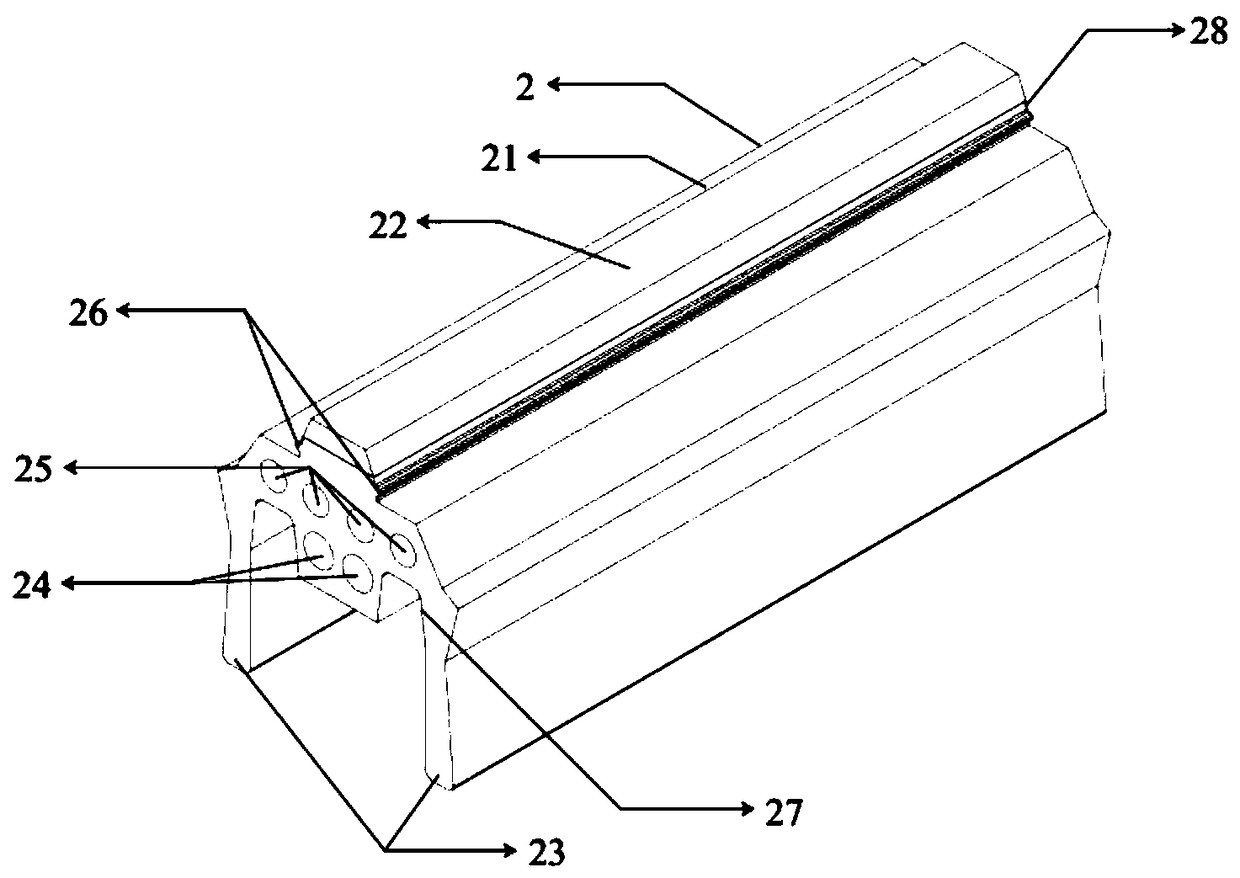

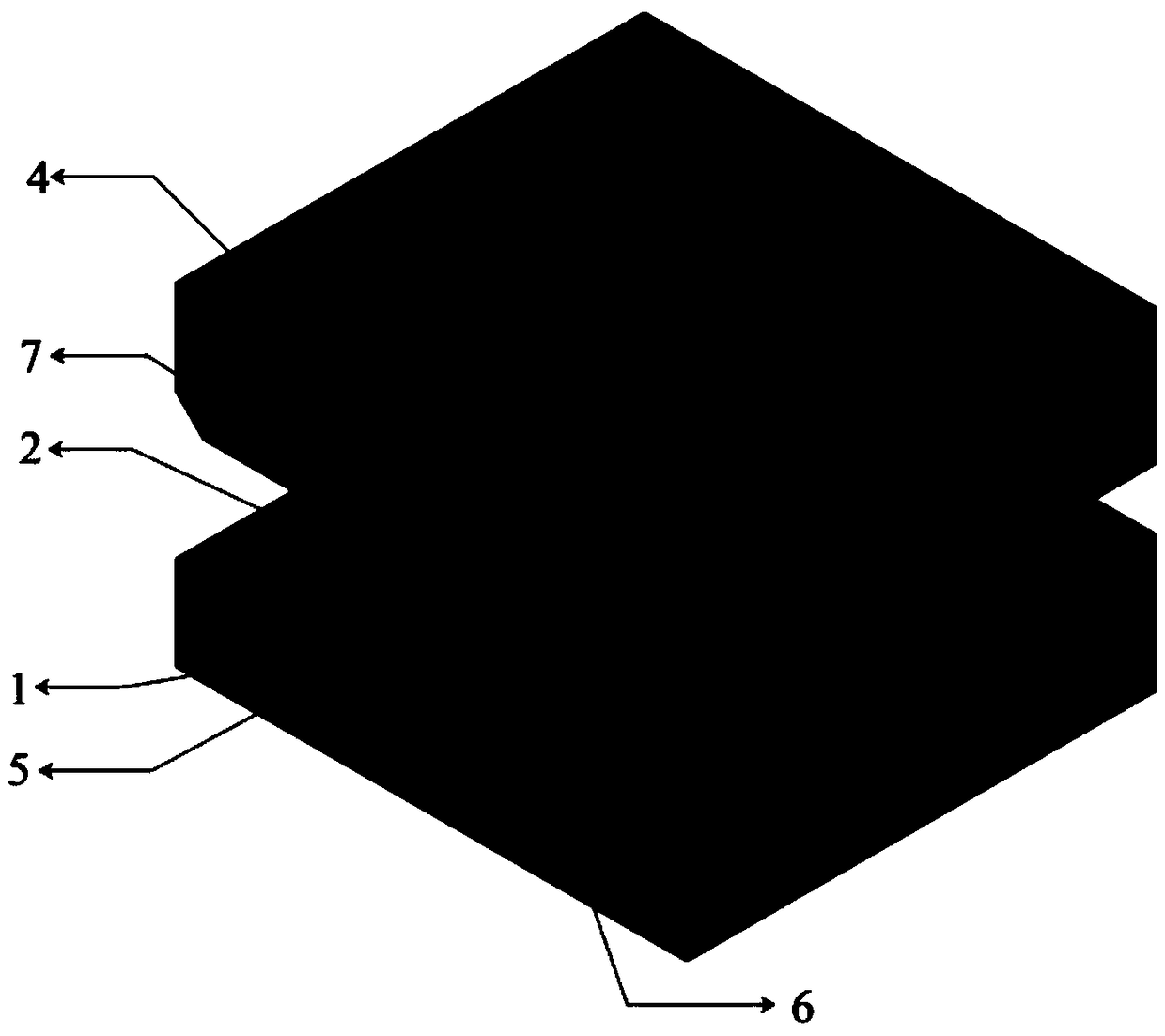

[0027] A shield tunnel segment seam gasket with a concave-convex cross-section is divided into a concave-shaped cross-section gasket 1 and a convex-shaped cross-section gasket 2 .

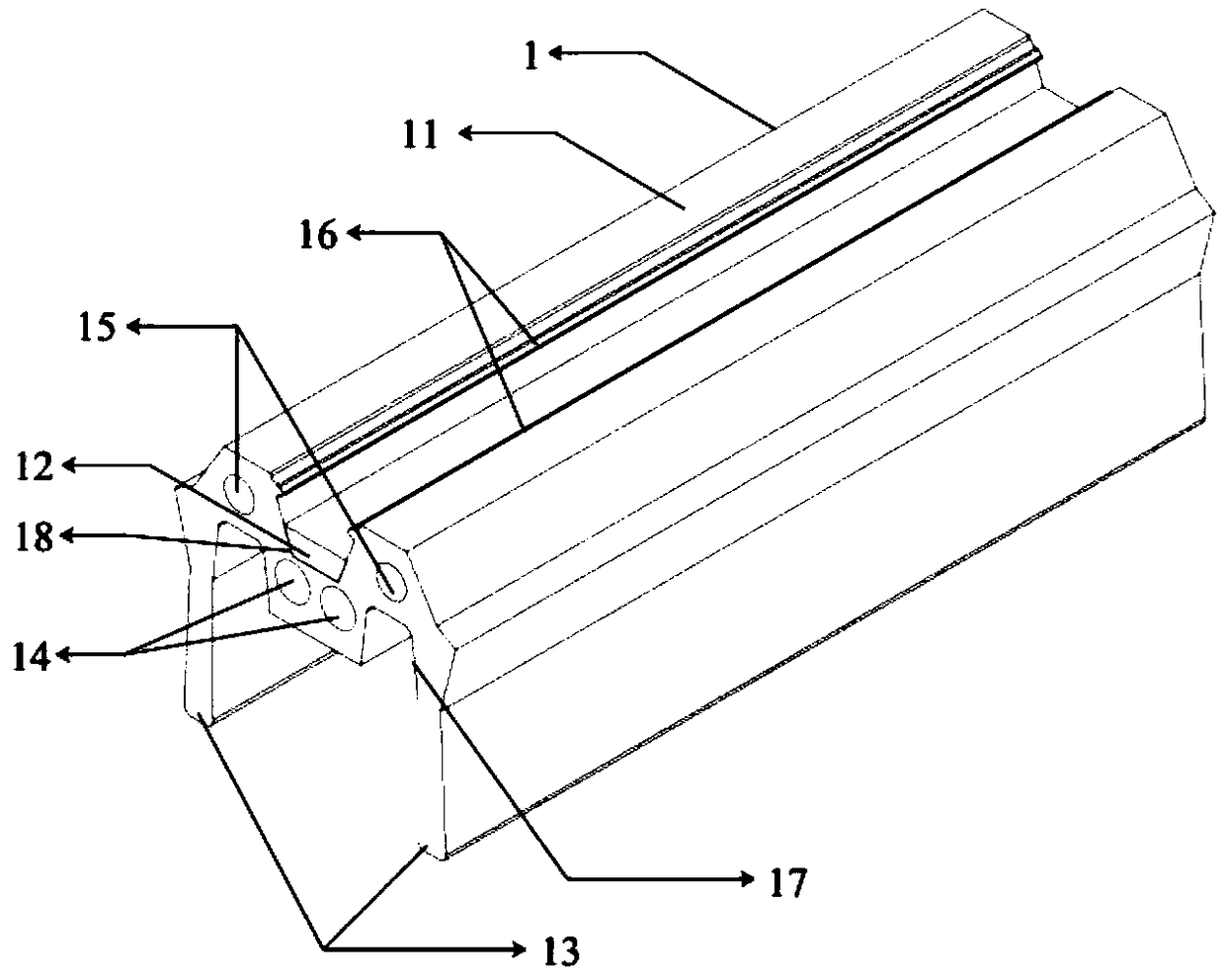

[0028] Such as figure 1 As shown, the waterproof gasket is a concave section gasket 1, the gasket is composed of EPDM rubber 11 and water-swellable rubber 12, and the top surface of the section of the EPDM rubber 11 is provided with convex ribs 16 The "concave" type pressure groove 18, the water-swellable rubber 12 is arranged at the bottom of the pressure groove 18. The section opening of the EPDM rubber 11 includes two grooves 17 and several through holes, and the two grooves 17 are symmetrically arranged on the bottom section of the concave section gasket 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com