Coal mine transportation and sale system

A technology for coal mines and coal yards, applied in the field of coal mine transportation and sales systems, can solve the problems of adulteration, lack of monitoring, unclear coal loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

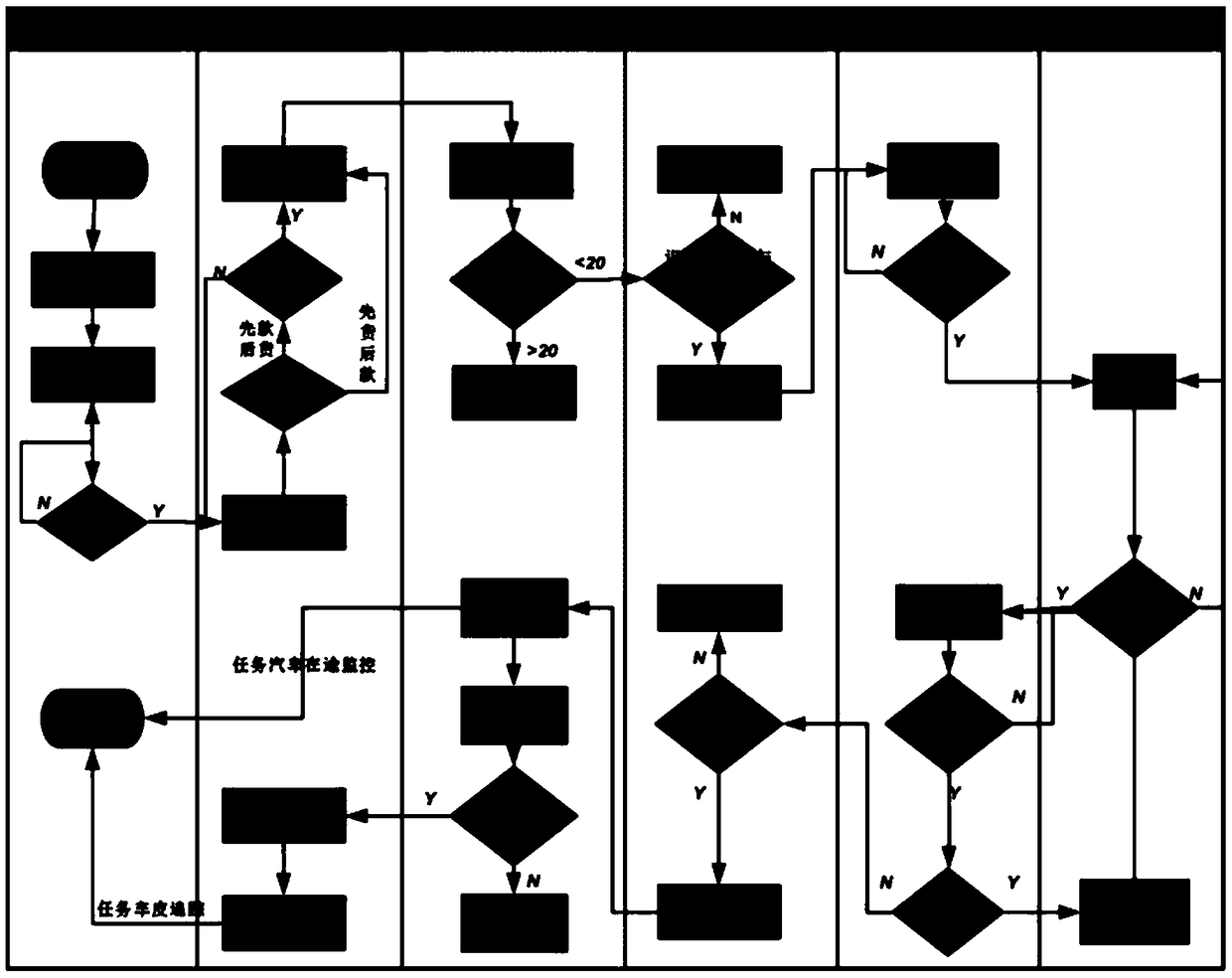

[0028] Coal vehicles entering and leaving the mine are manually released, which is inefficient. Vehicles entering and exiting the coal mine need to be manually released by the security guard at the gate, and the vehicle has not been recognized and automatically lifted when it arrives at the coal mine gate. To get out of the mine, the coal driver needs to get off the car and hand over the scale sheet to the security guard before manually controlling the lifting rod to go out of the mine

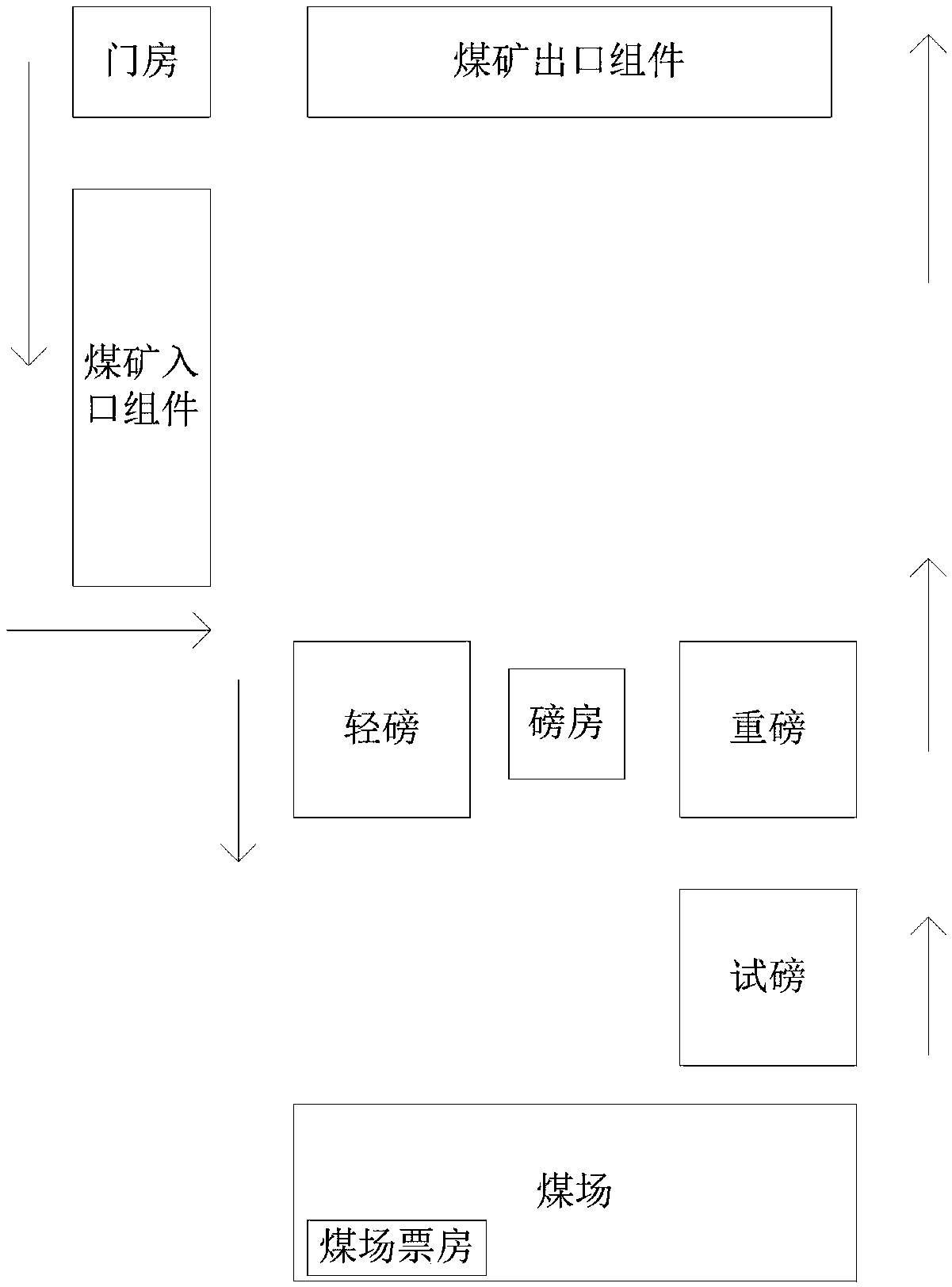

[0029] In order to solve the problem that there are many vehicles for transporting coal abroad, the management is difficult, and the vehicle scheduling is difficult in the peak season of coal, the coal mine transportation and sales system in this embodiment includes: gatehouse, coal mine entrance assembly, coal mine exit assembly, weighing room, light weight device, and heavy weight device , the coal mine entrance assembly includes the entrance door lever, the coal mine exit assembly includes ...

Embodiment 2

[0036] On the basis of the automatic entry and exit of coal transportation vehicles into and out of coal mines and coal platforms in Embodiment 1, in order to solve the defects that coal transportation vehicles are parked at will in the factory area and cannot effectively monitor the number of coal transportation vehicles in the factory area, the coal mine transportation and marketing system disclosed in this embodiment also includes Parking lot, the parking lot is for a number of coal transport vehicles to enter the parking lot along the path from the entrance of the coal mine to the parking lot and line up. They will drive out from the exit of the parking lot in sequence according to the order of entering the parking lot, and enter the coal yard after passing through the light weight device. coal. The purpose of setting up a parking lot in the coal mine transportation and sales system of this embodiment is to facilitate the centralized parking of coal transportation vehicles,...

Embodiment 3

[0041] On the basis of Embodiment 1 and Embodiment 2, the coal mine transportation and marketing system of this embodiment also includes a coal transportation vehicle management and control subsystem. The coal transportation vehicle management and control subsystem monitors the coal transportation vehicles in the transportation process. The monitoring includes but not It is limited to parking for a long time, parking in a sensitive area, not following the prescribed route, and exceeding the speed limit. In this embodiment, the purpose of setting the coal transportation vehicle management and control subsystem in the coal mine transportation and sales system is to prevent coal quality safety problems from occurring during transportation. The program module monitors the account balance information of the customer to which the coal transport vehicle belongs, and judges whether the weight of coal transported by the coal transport vehicle corresponding to the account balance informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com