A horizontally opposed engine with coaxially arranged cylinders

A coaxial arrangement, horizontally opposed technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of high manufacturing cost and maintenance cost of horizontally opposed engines, reduced service life of pistons and cylinders, uneven wear of cylinder walls, etc. , to improve energy utilization, prolong service life and eliminate uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

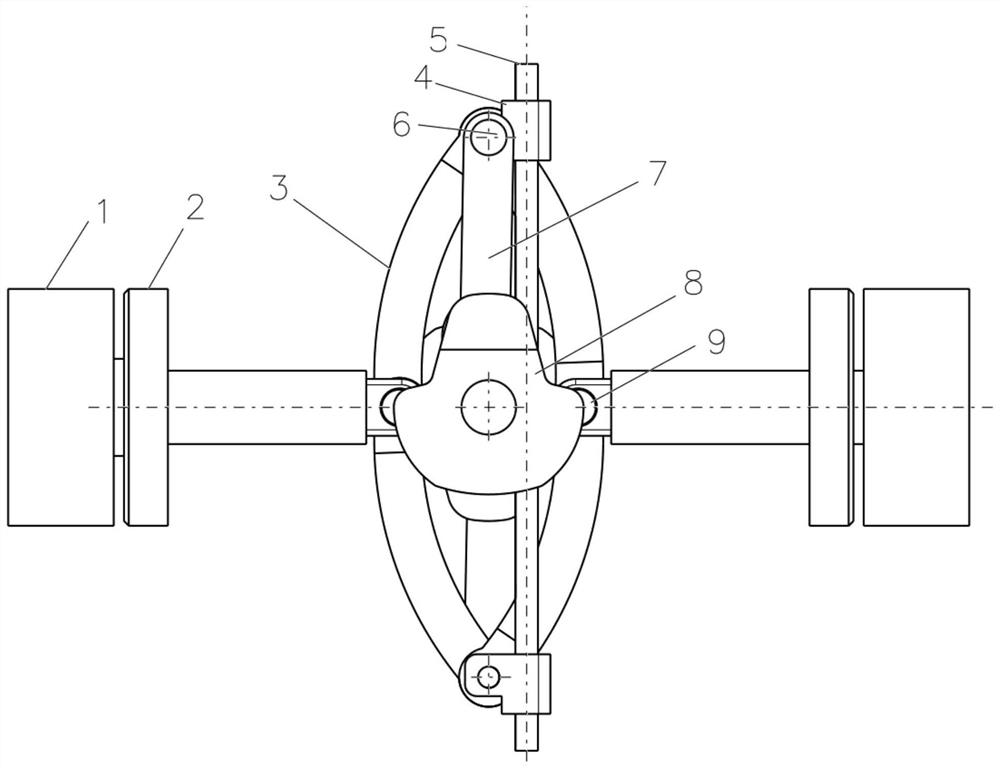

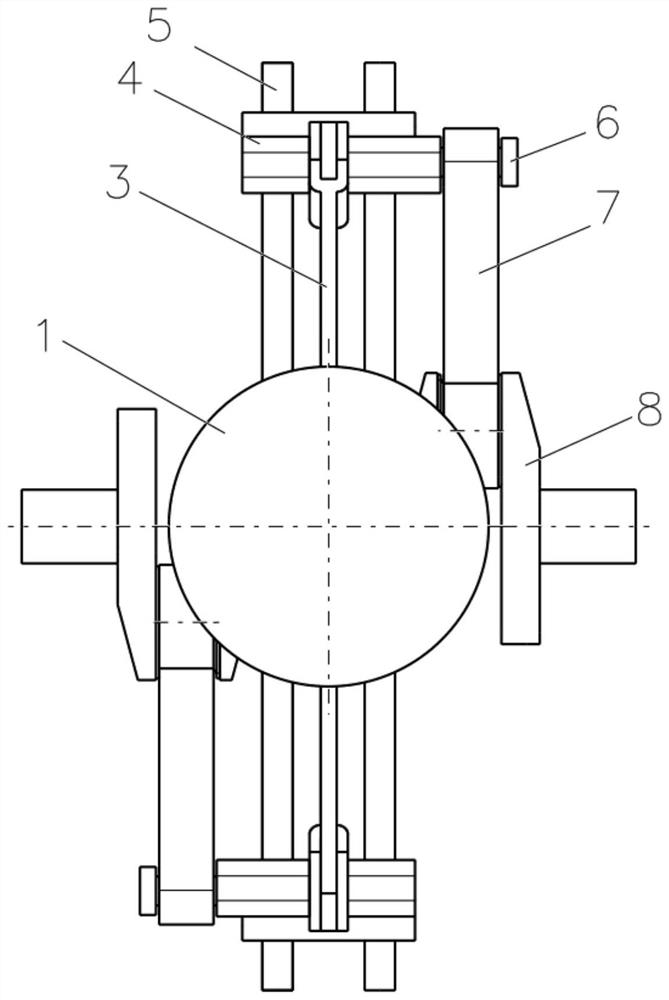

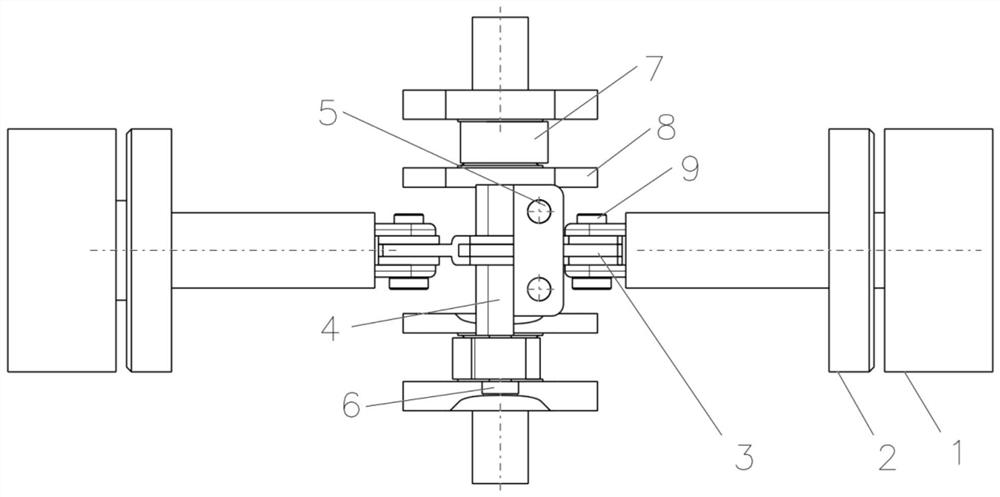

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] See attached Figure 1-3 , this embodiment provides a horizontally opposed engine with cylinders coaxially arranged, including: a piston 1, a piston connecting rod assembly 3, a piston connecting rod guide rod 5, a crankshaft connecting rod 7 and a crankshaft 8;

[0024] See attached Figure 4 , the piston connecting rod assembly 3 is an annular structure composed of arc-shaped first connecting rod 31, second connecting rod 32, third connecting rod 33, and fourth connecting rod 34 with the same structure; since the four connecting rods have the same structure , then the piston-connecting rod assembly 3 is symmetrical up and down, left and right.

[0025] Wherein the two connection points in the vertical direction of the piston connecting rod assembly 3 are respectively provided with a piston connecting rod guide block 4, and the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com