A tool and method for processing comb lines on the inner wall of a cylinder liner

A combing line and cylinder liner technology, which is applied in the field of tools for processing combing lines on the inner wall of the cylinder liner, to achieve the effects of low surface roughness, simple processing process, and easy control of precision and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

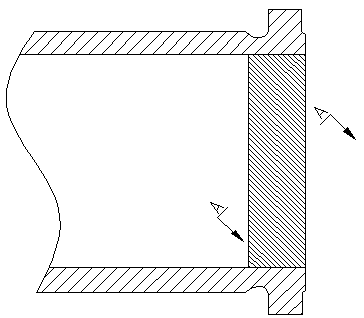

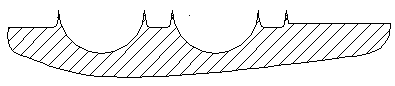

[0031] The present invention will be further described in detail below with reference to the embodiments: The present invention proposes a tool and method for processing a comb line capable of absorbing carbon deposits on the inner wall of a cylinder liner. The comb line processed by this method can effectively absorb the carbon deposits in the cylinder liner, making the carbon deposits gather in the non-working area of the cylinder liner, preventing the carbon deposits from slipping to the working area of the piston and cylinder liner, and affecting the normal operation of the cylinder .

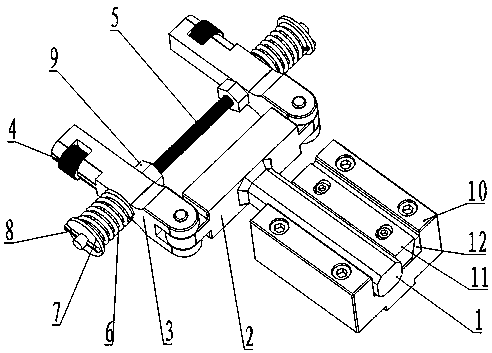

[0032] figure 1 It is a structural diagram of the wire combing knife and the tool holder in the present invention, including a tool holder fixed on the turret of the CNC lathe and a wire combing knife installed on the tool holder.

[0033] Wherein the wire combing knife comprises a cuboid handle 1, the other end of the handle 1 is welded with a crossbeam 2, the crossbeam 2 is perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com