Method for accurately detecting hole site of equipment by using total station

A technology of testing equipment and total station, which is applied to instruments, measuring devices, measuring instruments, etc., can solve the problems of inaccurate measurement of horizontal hole height, low measurement accuracy, and long operation time, so as to avoid accuracy loss and improve installation efficiency. , the effect of shortening the adjustment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

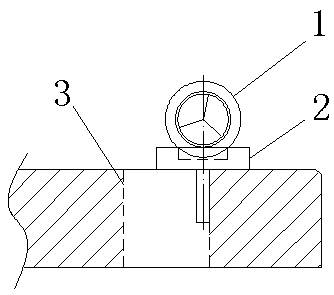

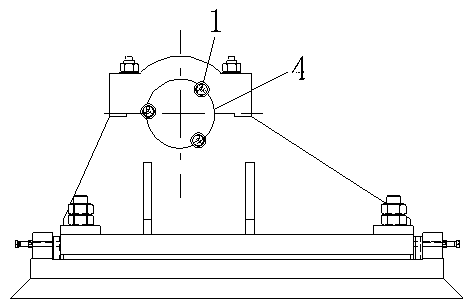

[0019] Such as figure 1 , figure 2 As shown, a method of using a total station to accurately detect the hole position of the equipment, including

[0020] Step 1. After the equipment is in place, make initial adjustments according to the drawing size.

[0021] Step 2. Set up the total station to the position where the hole position of the equipment can be seen through, and use the free station method to set up the station based on the pre-arranged three-dimensional control network.

[0022] Step 3. Use the spherical prism 1 and the matching magnetic base 2 to measure the three-dimensional coordinates of the pin holes 3 and 4. The measurement method is to attach the spherical prism 1 to the magnetic base 2, and use the The straight rod is close to the inside of the edge of the pin holes 3 and 4, and then the total station is used to measure the spherical prism to collect and record the three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com