Conical single-nozzle sampling system provided with two stages of shielding cases

A sampling system and shielding cover technology, applied in the field of conical single-nozzle sampling system, can solve the problems of unrepresentative sampling results, loss of airborne effluent pipeline, sampling distortion, etc., to achieve improved transmittance, high Transmittance, effect of reducing wall loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

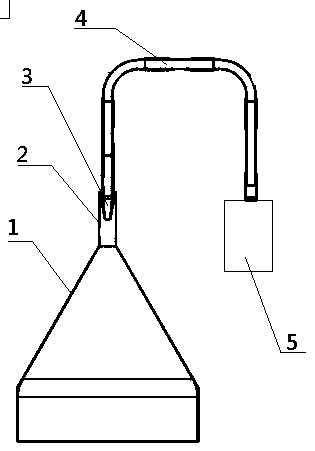

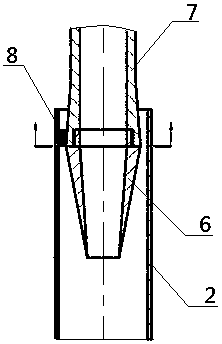

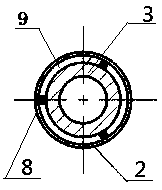

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a conical single-nozzle sampling system with a secondary shield is characterized in that it includes a primary shield 1, the primary shield 1 is funnel-shaped, and the end of the funnel is provided with a solid connection The secondary shielding cover 2, the inner end of the secondary shielding cover 2 is fixedly connected with a nozzle 3, the end of the nozzle 3 is threadedly connected with a pipeline 4, and the end of the pipeline is threadedly connected with an external exhaust gas emission monitoring device 5; the secondary shielding cover 2 is a round pipe structure, and its connection with the nozzle 3 is a welded connection with three connection points 8 in equal parts, and an airflow channel 9 is arranged between the two; the nozzle is composed of a nozzle 6 and a pipe body 7 , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap